Web thickness of the joint domain: For example, in the beam - column joint domain of a steel frame, it generally needs to meet tw≥(hb + hc)/90 (hb and hc are the cross - sectional heights of the beam and column) to prevent shear failure of the joint domain.

Connection method: It mostly follows the principle of "strong joints and weak components", such as full - penetration welding + bolt connection, ensuring that the bearing capacity of the joint is ≥ 1.2 times that of the component.

Sleeve parameters: For some sleeve - type joints, the width - thickness ratio of the sleeve is not more than 25, and the height of the sleeve is not less than 150% of the width of the sleeve.

Product Advantages

Cast steel joints: Can be designed into various complex shapes according to requirements, with beautiful appearance; mainly solid structures, high bearing capacity and strong anti - deformation ability; butt welds replace complex intersecting welds, reducing welding stress concentration.

Bolt - connected joints: Convenient for installation and disassembly, fast in construction speed, can effectively shorten the construction period, and facilitate later maintenance and renovation.

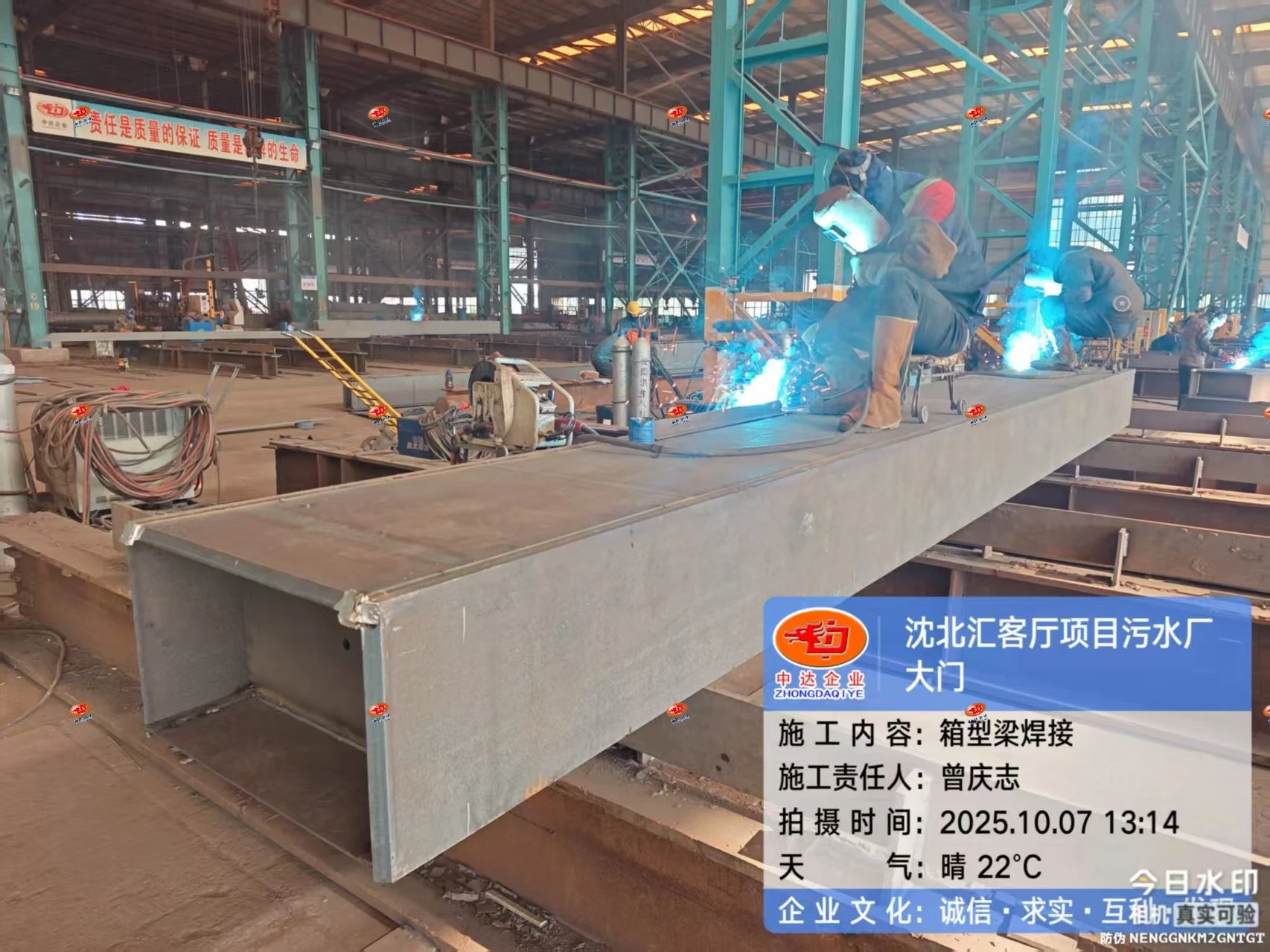

Welded joints: High connection stiffness and strong integrity, enabling the structure to better bear loads and transmit forces, ensuring the stability of the structure.

Selling Points Concerned by Purchasers

Reliability: Designed and manufactured in strict accordance with relevant standards and specifications, and tested for mechanical properties and quality inspection to ensure safety and reliability under various loads and environmental conditions.

Adjustability: Some joint designs have a certain adjustment margin, which can fine - tune the position and angle of components during on - site installation to adapt to deviations in actual construction.

Compatibility: Customized joint solutions can be provided according to different steel structure forms, component sizes and force - bearing characteristics to ensure perfect compatibility with the overall structure.

Shenyang Zhongda: Your Trusted Partner in Steel Structural Details

At Shenyang Zhongda Steel Structure Engineering Co., Ltd., we specialize in manufacturing top-quality steel structural details for diverse construction projects. Precision-engineered parts that meet the highest industry standards are made in our state-of-the-art buildings by our skilled staff. We offer dependable, low-cost solutions that are specially made to meet your needs because we are dedicated to new ideas and happy customers.

Product Description

To be the foundation of your building projects, our products are carefully planned and made. We have a wide range of parts that fit perfectly into your structure designs, from strong beams and columns to complex brackets and joints. Each part is made from high-quality steel, which gives it great strength, longevity, and load-bearing capacity.

Key Feature

- Precision-cut and welded connections for optimal structural integrity

- Corrosion-resistant coatings for enhanced longevity

- Customizable dimensions and specifications to suit project requirements

- Compliance with international quality standards (ASTM, ISO)

- Rigorous quality control throughout the manufacturing process

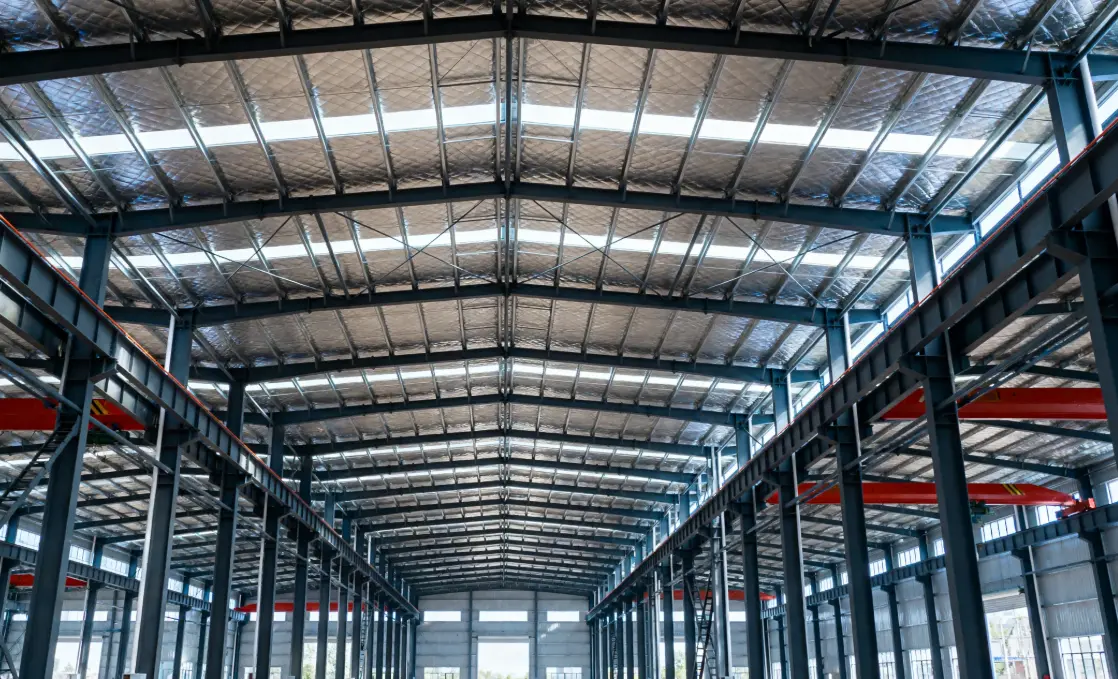

Whether you're working on industrial facilities, commercial buildings, or infrastructure projects, our products provide the reliable foundation you need for success.

Why Choose Us?

- Extensive experience in steel fabrication and engineering

- State-of-the-art production facilities for consistent quality

- Flexible manufacturing capabilities to meet diverse project needs

- Competitive pricing without compromising on quality

- Dedicated customer support and technical assistance

Function & Application

Our steel structural details serve as the critical components in various construction applications. They provide the essential framework for:

- Industrial warehouses and manufacturing facilities

- Multi-story commercial and residential buildings

- Bridges and transportation infrastructure

- Sports stadiums and large-span structures

- Modular and prefabricated construction projects

By choosing our products, you ensure structural stability, design flexibility, and efficient assembly on-site.

Production Process

- Design and Engineering: Our expert team creates detailed CAD drawings and structural analysis.

- Material Selection: We source high-quality steel that meets project specifications.

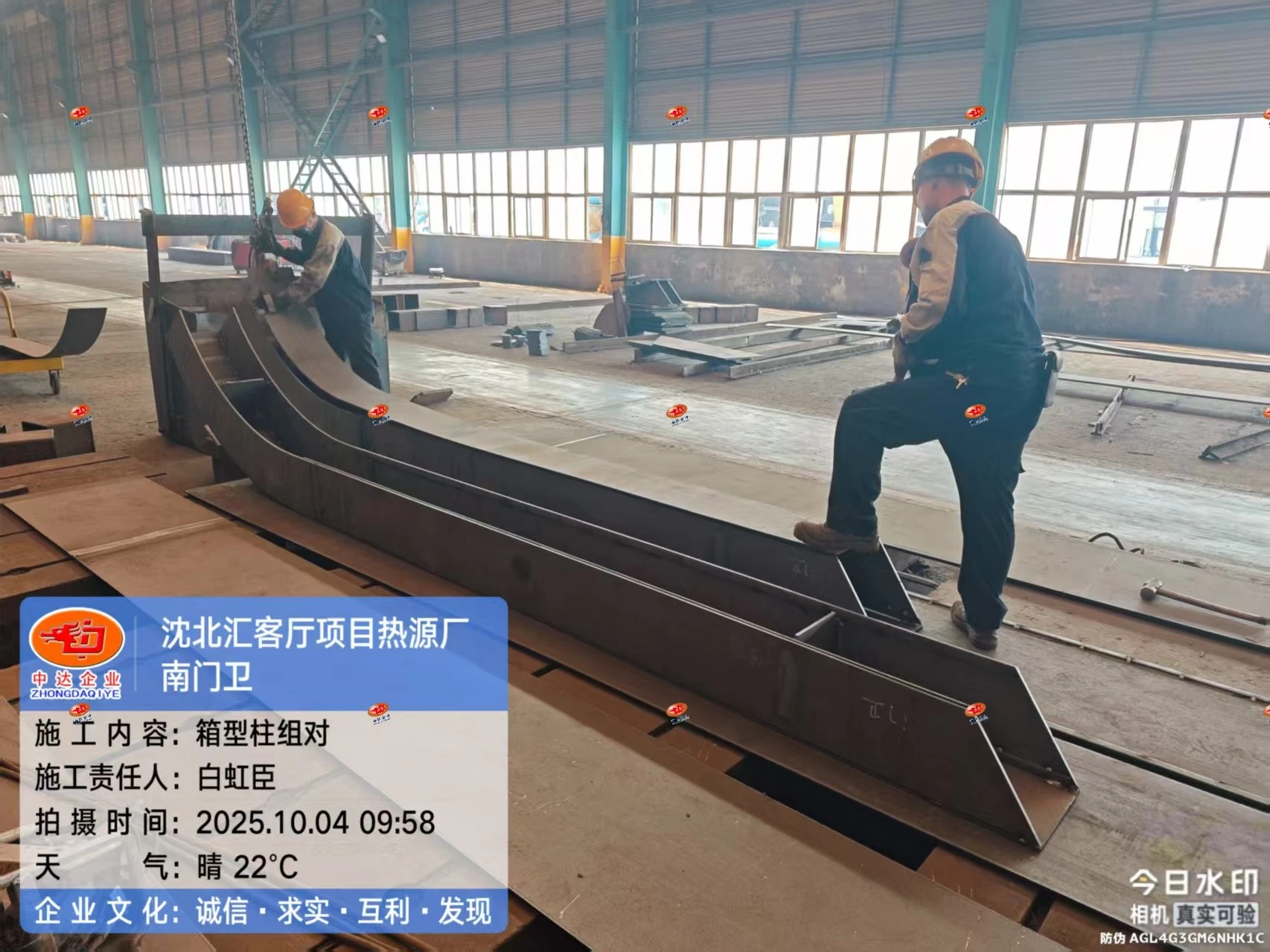

- Cutting and Shaping: Precision CNC machines cut and shape steel components.

- Welding and Assembly: Skilled welders join components using advanced techniques.

- Surface Treatment: Application of protective coatings for enhanced durability.

- Quality Inspection: Rigorous testing to ensure compliance with standards.

OEM & ODM Services

We offer comprehensive OEM and ODM services to meet your unique project requirements:

- Customized design and engineering support

- Prototype development and testing

- Flexible production quantities to suit your needs

- Specialized finishing options and treatments

- Full documentation and certification support

Partner with us to bring your innovative structural concepts to life.

Packaging and Delivery

- Secure packaging to prevent damage during transport

- Efficient logistics solutions for timely delivery

- Global shipping capabilities to serve international clients

- Flexible delivery options to accommodate project schedules

Qualification of Company

Shenyang Zhongda Steel Structure Engineering Co., Ltd. holds the prestigious First-Class Steel Structure Engineering Qualification issued by China's Ministry of Housing and Urban-Rural Development. This certification, along with our ISO 9001 quality management system, demonstrates our commitment to excellence and reliability in the steel structure industry.

FAQs

- Q: What is the lead time for custom products?

A: Lead times vary based on project complexity and volume. Typically, we can deliver within 4-8 weeks after order confirmation. - Q: Can you provide engineering support for my project?

A: Yes, our experienced engineering team offers comprehensive design and technical support throughout your project. - Q: Do you offer on-site installation services?

A: While we primarily focus on manufacturing, we can recommend trusted partners for installation services. - Q: What quality control measures do you have in place?

A: We implement strict quality control at every stage, including material testing, in-process inspections, and final product verification. - Q: Are your products suitable for seismic zones?

A: Yes, we can design and manufacture components that meet seismic design requirements for various regions.

Contact & Support

Ready to elevate your construction projects with our premium steel structural details? Contact our expert team today for personalized assistance and quotations. We're committed to helping you achieve your structural engineering goals with precision and efficiency.

Email: postmaster@zd-steels.com

Trust Shenyang Zhongda Steel Structure Engineering Co., Ltd. for all your steel structural needs – where quality meets innovation.

YOU MAY LIKE

_副本_1760170327027.jpg)