2. Certifications: ISO 9001, CE, SGS. Third - party NDT reports available.

3. Custom services: Support non - standard sizes, offer galvanizing/painting, accept custom drawings.

4. Delivery: 15 days for regular, 10 days for expedited (10% extra).

5. Applications: Factory load - bearing beams, bridge supports. Bending strength ≥345MPa for large - span.

6. Cost: Saves 17% on steel vs. I - beams. Bulk orders have tiered pricing.

High-Frequency Welded I-Section Girder: Superior Strength for Your Structural Needs

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of High-Frequency Welded I-Section girders. Our advanced technology and rigorous quality control ensure that our products offer unparalleled strength, precision, and cost-effectiveness for your large-scale construction projects.

Product Description

Our products are engineered to meet the demanding requirements of modern construction. Utilizing state-of-the-art high-frequency welding technology, we create I-section beams that offer superior strength-to-weight ratios compared to traditional rolled I-beams. These girders are ideal for bridges, industrial facilities, and high-rise buildings where structural integrity is paramount.

Key features of our products include:

- Customizable dimensions to suit your project specifications

- Excellent load-bearing capacity and bending strength (≥345MPa)

- Reduced material usage, saving up to 15% on steel compared to standard I-beams

- Compliance with ASTM A992 and GB/T 11263-2010 standards

- Available in Q235B and Q345B steel grades for versatile applications

Quality Control

At Zhongda, quality is our top priority. Our products undergo rigorous testing and inspection processes:

- 100% ultrasonic testing of welds

- Third-party non-destructive testing (NDT) reports provided

- Dimensional accuracy checks using advanced measurement equipment

- Material composition analysis to ensure compliance with specified standards

Why Choose Us?

- Industry-leading expertise with over 60 landmark projects completed

- Full-chain integration from R&D to fabrication and construction

- 60,000-ton annual production capacity ensures timely delivery

- Advanced equipment including CNC ultra-thick plate cutting and automated welding lines

- 70% client retention rate, reflecting our commitment to customer satisfaction

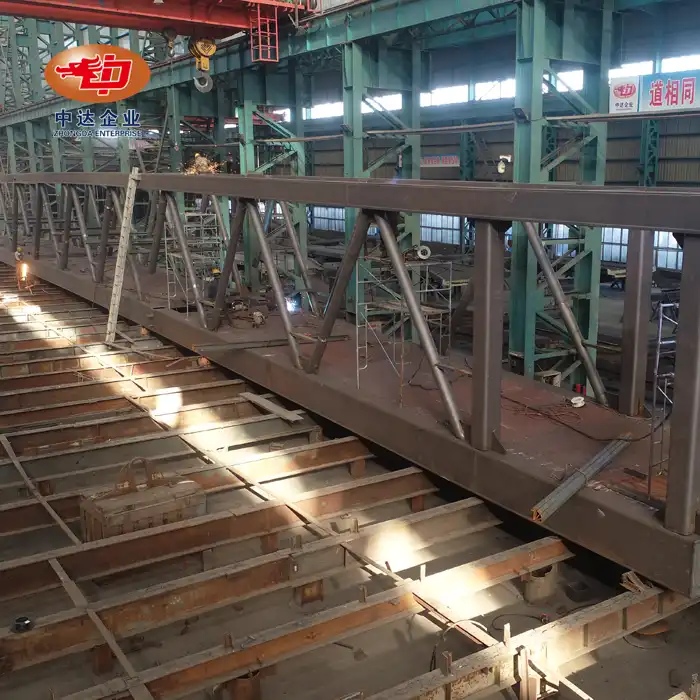

Production Process

Our streamlined production process for High-Frequency Welded I-Section girders includes:

- Precision cutting of steel plates

- High-frequency welding of web and flanges

- Quality inspection and non-destructive testing

- Surface treatment (if required)

- Packaging and shipping

OEM & ODM Services

We offer comprehensive OEM and ODM services for the products:

- Customizable dimensions: Web heights from 80-400mm and flange widths from 100-350mm

- Material options: Q235B/Q345B or custom specifications upon request

- Specialized welding: Fully penetrated welds with staggered seams (≥200mm)

- Surface treatments: Galvanizing or painting available

- Design support: We accept and work with custom CAD/3D files

- Flexible production: Both standard and non-standard sizes (e.g., extra-wide flanges, special cross-sections)

- Quick turnaround: Regular orders in 15 days, expedited options available

Project Cases

Our products have been successfully employed in numerous high-profile projects:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion

- Multiple industrial plants for leading state-owned enterprises

- Overseas equipment components, including Australian mining crushing stations

These projects showcase our ability to deliver high-quality, precision-engineered girders for diverse applications.

Cases

Certifications

Our commitment to quality is backed by:

- ISO 9001:2015 Quality Management System

- CE marking for European market compliance

- SGS material certifications

Packaging and Delivery

We ensure secure packaging and efficient delivery:

- Custom-designed packaging ensures maximum protection for your products during transit, safeguarding them from damage and maintaining their quality from our facility to your site.

- Flexible shipping options are tailored to fit your project timelines and logistical needs, allowing you to choose the most convenient and efficient delivery schedule for your business.

- Standard delivery within 15 days offers reliable service for most orders, while our expedited 10-day option is available for urgent projects, ensuring you receive your materials quickly when time is critical.

FAQ

Q: What are the advantages of the products over rolled I-beams?

A: Our girders offer higher strength-to-weight ratios, customizable dimensions, and up to 15% material savings, making them more cost-effective and versatile for large-scale projects.

Q: Can you provide girders for international projects?

A: Yes, we comply with international standards like ASTM and EN 1090, enabling seamless integration into global EPC project chains.

Contact Us

Ready to elevate your structural projects with our High-Frequency Welded I-Section girders? Contact our expert team at Ava@zd-steels.com for personalized solutions and competitive quotes.

YOU MAY LIKE