2. Certifications: It has EN10219 Certification and is compliant with EU steel structure welding standards.

3. Customization Services: Multi - Cavity Composite Sections are available for complex designs, and concrete filling can enhance fire resistance performance.

4. Delivery Period: Standard orders take 30 days, while express orders take 22 days with an additional 15% rush fee.

5. Application Scenarios: It is used in Super High - Rise Building Core Tubes and Heavy Industrial Factory Columns, with seismic resistance up to Grade 8 earthquake protection.

6. Quality Assurance: The product has a Fully Automated Submerged Arc Welding Process and the weld quality is Grade 1 (the highest standard).

Box-Section Lattice Column: Unrivaled Strength for Your Megastructures

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading Box-Section Lattice Column manufacturer and supplier. Our advanced fabrication techniques and stringent quality control ensure superior products for your construction needs. Zhongda's products offer unparalleled strength, durability, and customization options, making us the preferred choice for discerning procurement managers and engineers worldwide.

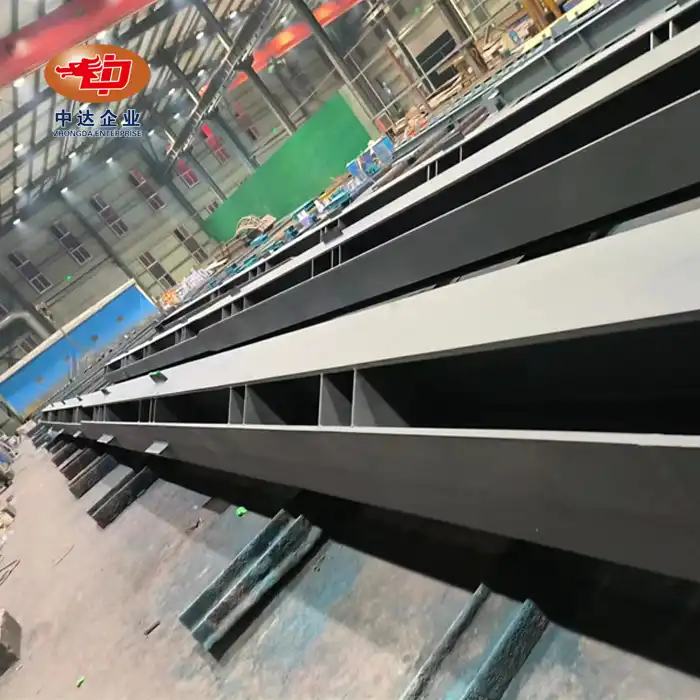

Product Description

Our products are engineered to provide exceptional load-bearing capacity and structural integrity for your most demanding projects. Crafted from high-grade Q345C steel, these columns feature a robust box section design with internal stiffeners, offering superior resistance to bending and torsional forces. Available in dimensions ranging from 200×200mm to 600×600mm, with wall thicknesses of 10-40mm, our columns are ideal for super high-rise buildings, heavy industrial facilities, and seismic-resistant structures up to Grade 8 earthquake protection.

Product Features

- Exceptional load-bearing capacity

- Enhanced structural stability with internal stiffeners

- Customizable dimensions and wall thickness

- Superior resistance to bending and torsional forces

- Suitable for high-rise and heavy industrial applications

- Seismic resistance up to Grade 8

Box-Section Lattice Column

Quality Control

At Zhongda, we prioritize quality at every step. Our fully automated submerged arc welding process ensures consistent, Grade 1 weld quality - the highest industry standard. Each product undergoes rigorous non-destructive testing, including ultrasonic and X-ray inspections, guaranteeing structural integrity and longevity for your projects.

Why Choose Us?

With our Class I Steel Structure Professional Contracting Qualification and ISO certifications, Zhongda offers unmatched expertise in the product manufacturing. Our vertically integrated capabilities, from R&D to precision fabrication, ensure cost-effectiveness and timely delivery. Choose Zhongda for superior products backed by comprehensive technical support and after-sales service.

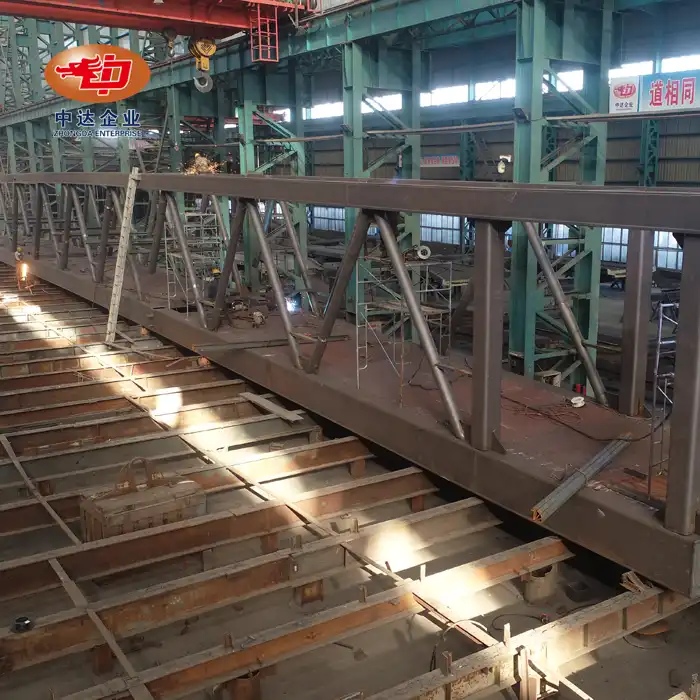

Production Process

Our state - of - the - art facility stands as a paragon of modern manufacturing prowess. Equipped with cutting - edge technology, we utilize CNC ultra - thick plate cutting to precisely shape even the most challenging materials. The 3 - axis CNC drilling systems enable us to create holes with pinpoint accuracy, crucial for complex assemblies. Complemented by automated welding lines, our production process is streamlined. This setup not only ensures high - precision products but also allows us to manufacture them efficiently and with unwavering consistency, meeting the strictest industry standards and customer demands.

OEM & ODM Services

Zhongda offers extensive customization options to meet your specific project requirements. Our multi-cavity composite sections cater to complex designs, while concrete filling enhances fire resistance performance. We work closely with clients to develop bespoke solutions, leveraging our R&D expertise and BIM-based digital design capabilities. Whether you need specialized dimensions, unique material compositions, or tailored load-bearing specifications, our team is ready to deliver. With our EN10219 certification and compliance with EU steel structure welding standards, we ensure your custom products meet global quality benchmarks.

Project Cases

Our Box-Section Lattice Column have been integral to numerous landmark projects, including:

- The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Expansion of the Jingha Expressway

- Multiple super high-rise buildings across China

- Heavy industrial facilities for mining and petrochemical sectors

These projects showcase our ability to deliver large-scale, complex structures with precision and reliability, consistently meeting or exceeding client expectations.

Certifications

- ISO 9001/14001/45001

- EN10219 Certification

- Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery

We ensure secure packaging for safe transportation. Standard orders are delivered within 30 days, while express orders can be completed in 22 days with a 15% rush fee.

FAQ

Q: What is the maximum load-bearing capacity of your products?

A: The load-bearing capacity varies based on dimensions and design. Our engineering team can provide specific calculations for your project requirements.

Q: Can these columns be used in corrosive environments?

A: Yes, we offer weathering steel options and protective coatings for enhanced corrosion resistance in challenging environments.

Contact Us

Ready to elevate your construction projects with our premium Box-Section Lattice Column? Contact our expert team at Ava@zd-steels.com for personalized solutions and quotations.

YOU MAY LIKE