2. Material: Q355D steel pipe, 600 - 2500mm dia., 14 - 40mm thickness.

3. Seismic: Concrete - filled, ≤1/300 lateral displacement.

4. Anti - Corrosion: Arc - sprayed aluminum (150μm) + fluorocarbon topcoat (C5 - M).

5. Certifications: EN 1090 - 2 EXC4, UT inspection report.

6. Construction: Patented sleeve positioning, ±1mm accuracy.

7. Delivery: Standard in 30 days, complex in 46 days.

Bent Arc-Shaped Steel Columns: Precision-Engineered Excellence from Shenyang Zhongda

As a leading Bent Arc-Shaped Steel Column manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled quality and innovation. Our advanced manufacturing capabilities and rigorous quality control ensure superior products that meet the most demanding project requirements.

Product Description:

Our products are the epitome of structural elegance and strength. Precision-engineered using state-of-the-art 3D CNC pipe bending technology, these columns boast an impressive error tolerance of ≤2mm/m, supporting intricate spiral and wave shapes. Crafted from premium Q355D steel pipe with diameters ranging from 600-2500mm and wall thicknesses of 14-40mm, our columns deliver exceptional load-bearing capacity and durability.

The concrete-filled steel tube composite structure ensures superior seismic performance, with a lateral displacement angle of ≤1/300. This makes our products ideal for projects in earthquake-prone regions, providing both safety and peace of mind.

Product Features:

- High-precision 3D CNC bending for complex shapes

- Q355D steel for superior strength and durability

- Concrete-filled design for enhanced seismic resistance

- Customizable dimensions to suit project requirements

- Arc-sprayed aluminum (150μm) + fluorocarbon topcoat for C5-M grade corrosion protection

Quality Control:

Our commitment to quality is evidenced by our EN 1090-2 EXC4 certification and comprehensive UT inspection reports. Each Bent Arc-Shaped Steel Column undergoes rigorous testing to ensure it meets or exceeds industry standards, guaranteeing the highest level of structural integrity and performance.

Why Choose Us?

Zhongda's expertise in products is backed by our full-chain technical integration, R&D-driven innovation, and proven track record in mega-project execution. Our 70% client retention rate and ability to reduce lead times by 20-30% demonstrate our commitment to customer satisfaction and project success.

Production Process:

Our streamlined production process includes 3D modeling, CNC bending, welding, surface treatment, and quality inspection, ensuring each column meets exact specifications.

OEM & ODM Services:

At Zhongda, we understand that every project is unique. Our OEM and ODM services offer tailored solutions to meet your specific requirements. Leveraging our advanced 3D CNC pipe bending technology and expertise in special-shape forming, we can create custom products that perfectly align with your architectural vision.

Our team of experienced engineers works closely with clients to develop innovative designs, optimize material usage, and enhance structural performance. Whether you need columns with unique curvatures, special load-bearing capacities, or specific aesthetic features, our OEM and ODM capabilities ensure your project stands out.

We pride ourselves on our ability to handle complex shapes and designs, with delivery timelines of 30 days for standard models and 45 days for more intricate configurations. Our patented sleeve positioning technology guarantees assembly accuracy within ±1mm, ensuring seamless integration into your construction process.

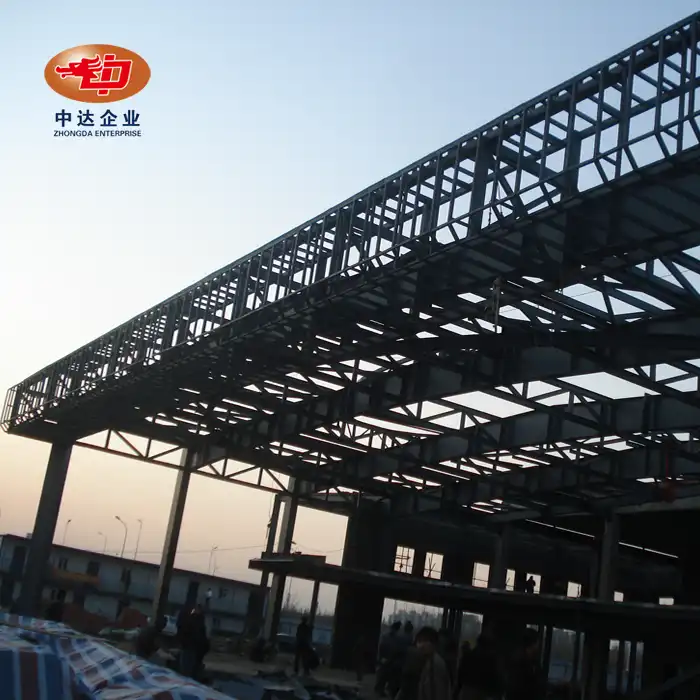

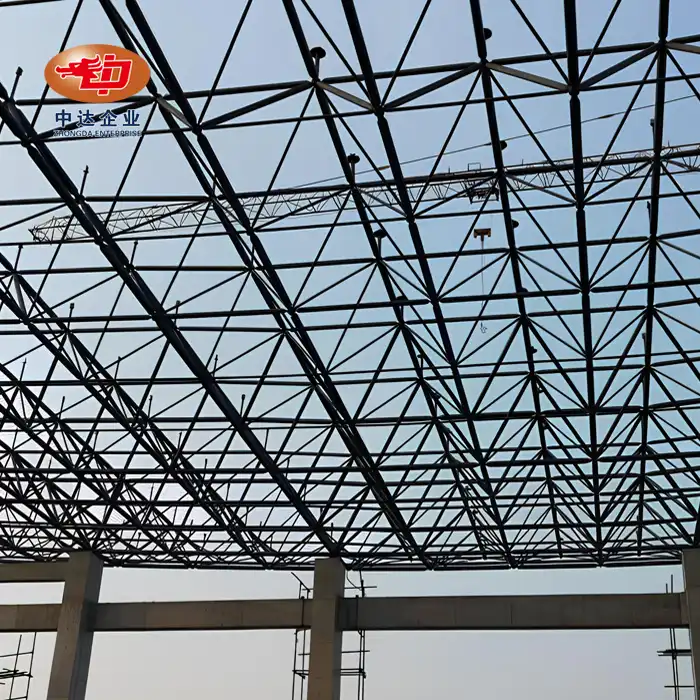

Project Cases:

Our products have been instrumental in numerous landmark projects. The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge showcases the structural integrity and aesthetic appeal of our columns. In industrial applications, our columns have been used in Australian mining crushing stations, demonstrating their versatility and durability in demanding environments.

For the Jingha Expressway expansion, our products provided both functional support and architectural distinction. These projects highlight our ability to deliver high-quality, custom solutions for diverse applications, from infrastructure to industrial facilities.

Certifications:

EN 1090-2 EXC4, ISO 9001, ISO 14001, ISO 45001

Packaging and Delivery:

Secure packaging ensures safe transportation. We offer flexible shipping options to meet your project timeline and location requirements.

FAQ:

Q: Can you customize the dimensions of the products?

A: Absolutely! We offer full customization to meet your specific project needs.

Q: What is the lead time for custom orders?

A: Standard models typically take 30 days, while complex shapes may require up to 45 days.

Q: Do you provide technical support for installation?

A: Yes, our expert team offers comprehensive technical support throughout the project lifecycle.

Contact Us:

Ready to elevate your project with our Bent Arc-Shaped Steel Columns? Contact us at Ava@zd-steels.com for a personalized consultation and quote. Let Zhongda be your partner in structural excellence!

YOU MAY LIKE