2. Certification: ISO 9001 and load calculation report.

3. Customization: Bolted connection for easy handling; for warehouse/logistics upgrade.

4. Delivery: Standard in 10 days, galvanized +5 days.

5. Applications: Equipment platforms, multi - level mezzanines; load ≥5 kN/m².

6. Anti - corrosion: Hot - dip galvanizing (≥120μm zinc); fluorocarbon as alternative.

7. Weather resistance: 30 years.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Beam Platform Manufacturer & Supplier

Shenyang Zhongda Steel Structure Engineering Co., Ltd. excels in beam platform manufacturing, offering superior quality, customization, and technical expertise. Our ISO-certified processes and full-chain integration ensure unmatched precision and efficiency in the production.

Beam Platform Product Description

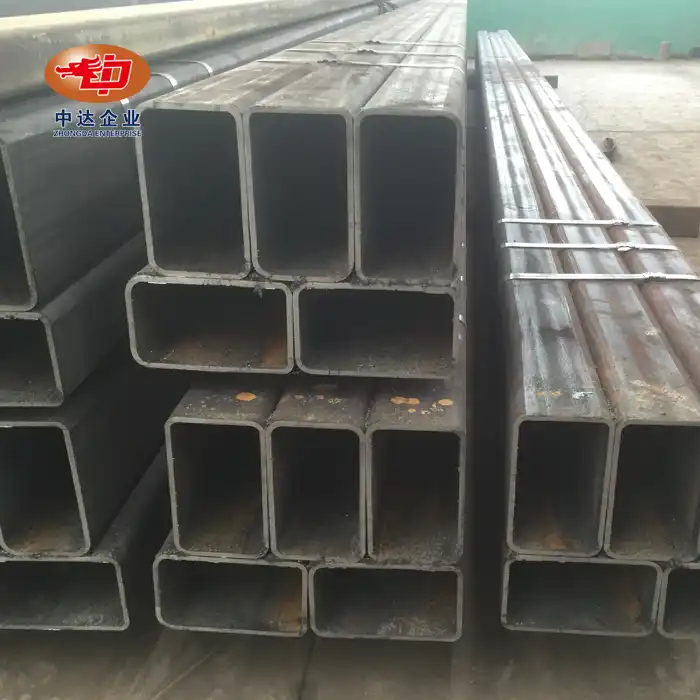

Our high-performance products are engineered for durability and versatility, perfect for large-scale construction and industrial applications. Crafted from premium Q345B hot-rolled H-shaped steel, these platforms offer:

- Customizable column sections (200×200mm to 400×400mm)

- Impressive beam spans up to 12 meters

- Uniform load capacity exceeding 5 kN/m²

- Bolted connection design for easy assembly and disassembly

- Adaptability for warehouse upgrades and logistics platforms

- Suitability for equipment operation platforms and multi-level steel mezzanines

Our products combine strength with flexibility, meeting diverse project requirements while ensuring safety and efficiency.

Beam Platform Features

- Superior load-bearing capacity

- Modular design for easy installation and reconfiguration

- Corrosion-resistant options with hot-dip galvanizing (zinc layer ≥120μm)

- Weather-resistant solutions lasting up to 30 years

- Compliance with international safety standards

Quality Control for Beam Platform

At Zhongda, quality is paramount. Our beam platform undergo rigorous testing and inspection:

- Non-destructive testing for structural integrity

- CNC precision fabrication ensuring dimensional accuracy

- Automated welding for consistent joint quality

- Comprehensive load calculation reports for each design

Why Choose Zhongda for Your Beam Platform Needs?

- Industry-leading R&D capabilities

- 60,000-ton annual production capacity

- Advanced equipment including 300mm CNC ultra-thick plate cutting

- Expertise in complex project execution using BIM technology

- 70% client retention rate and 20-30% reduced lead times

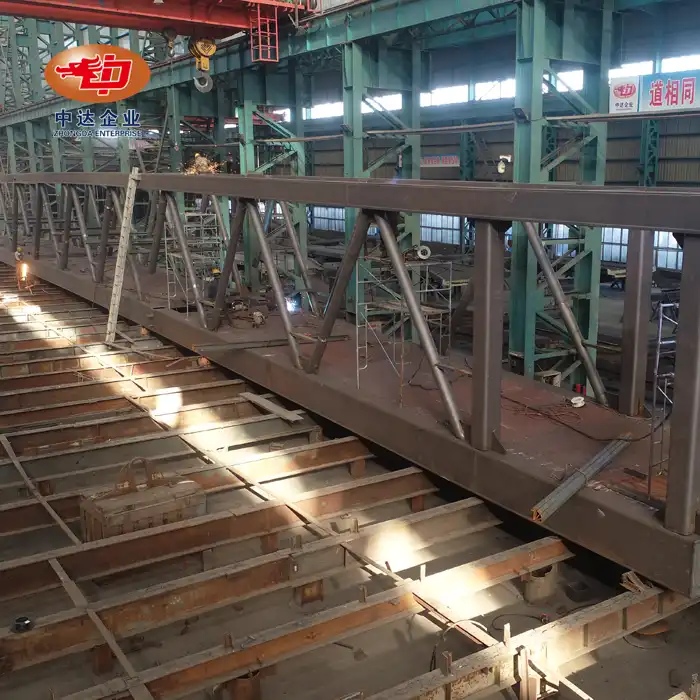

Beam Platform Production Process

Our streamlined process includes:

- Design & Engineering involves a team of skilled professionals creating innovative blueprints, considering functionality and aesthetics for optimal product design.

- Precision Fabrication utilizes advanced machinery to transform raw materials into components with high - accuracy cuts, bends, and shapes.

- Quality Inspection employs strict protocols and advanced testing tools to ensure each product meets the highest quality and safety standards.

- Surface Treatment uses processes like painting, plating, and polishing to enhance appearance, durability, and corrosion resistance of products.

- Packaging & Delivery focuses on secure wrapping and efficient shipping methods to ensure products reach clients in perfect condition on time.

OEM & ODM Beam Platform Solutions

Zhongda offers comprehensive OEM and ODM services for the products:

- Customized designs based on specific project requirements

- Material selection optimization for cost-efficiency

- Innovative solutions for unique architectural challenges

- Integration of advanced features like built-in utilities or modular expansion capabilities

- Collaborative engineering support throughout the project lifecycle

We work closely with clients to develop product solutions that perfectly align with their operational needs and aesthetic preferences.

Beam Platform Project Cases

Our beam platform have been successfully implemented in various high-profile projects:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion

- Industrial plant mezzanines for major manufacturers

- Multi-level warehouse platforms for logistics giants

- Custom equipment platforms for Australian mining operations

These projects showcase our ability to deliver products that meet diverse and demanding specifications.

Certifications for Beam Platform ISO 9001/14001/45001 certified

- Class I Steel Structure Professional Contracting Qualification

- Compliance with EN 1090, AWS, and JIS standards

Packaging and Delivery of Beam Platform

- Secure packaging for long-distance transport

- Standard orders delivered within 10 days

- Galvanized orders: additional 5 days

- Global shipping capabilities

Frequently Asked Questions about Beam Platform

Q: Can products be customized for specific load requirements?

A: Yes, we design platforms to meet your exact load specifications.

Q: What's the lifespan of your products?

A: With proper maintenance, our platforms can last 30+ years, especially with galvanization.

Q: Do you provide installation services?

A: We offer comprehensive installation support and can arrange full installation services if required.

Contact Us for Your Beam Platform Needs

Ready to elevate your project with our superior beam platform? Contact our expert team at Ava@zd-steels.com for a personalized consultation and quote. Let Zhongda be your trusted partner in structural excellence.

YOU MAY LIKE