2. Certifications: CE, compliant with FEM 1.001 Crane Rail Standards.

3. Customization: Crane beams for 5 - 50 ton systems, rail clamp bolt holes for crane rail install.

4. Delivery: Standard specs in 15 days, non - standard in 25 days.

5. Quality: Fatigue strength ≥2×10^6 cycles, 15 - year warranty.

6. Cost: 21% savings vs welded H - beams, ideal for small/medium plants.

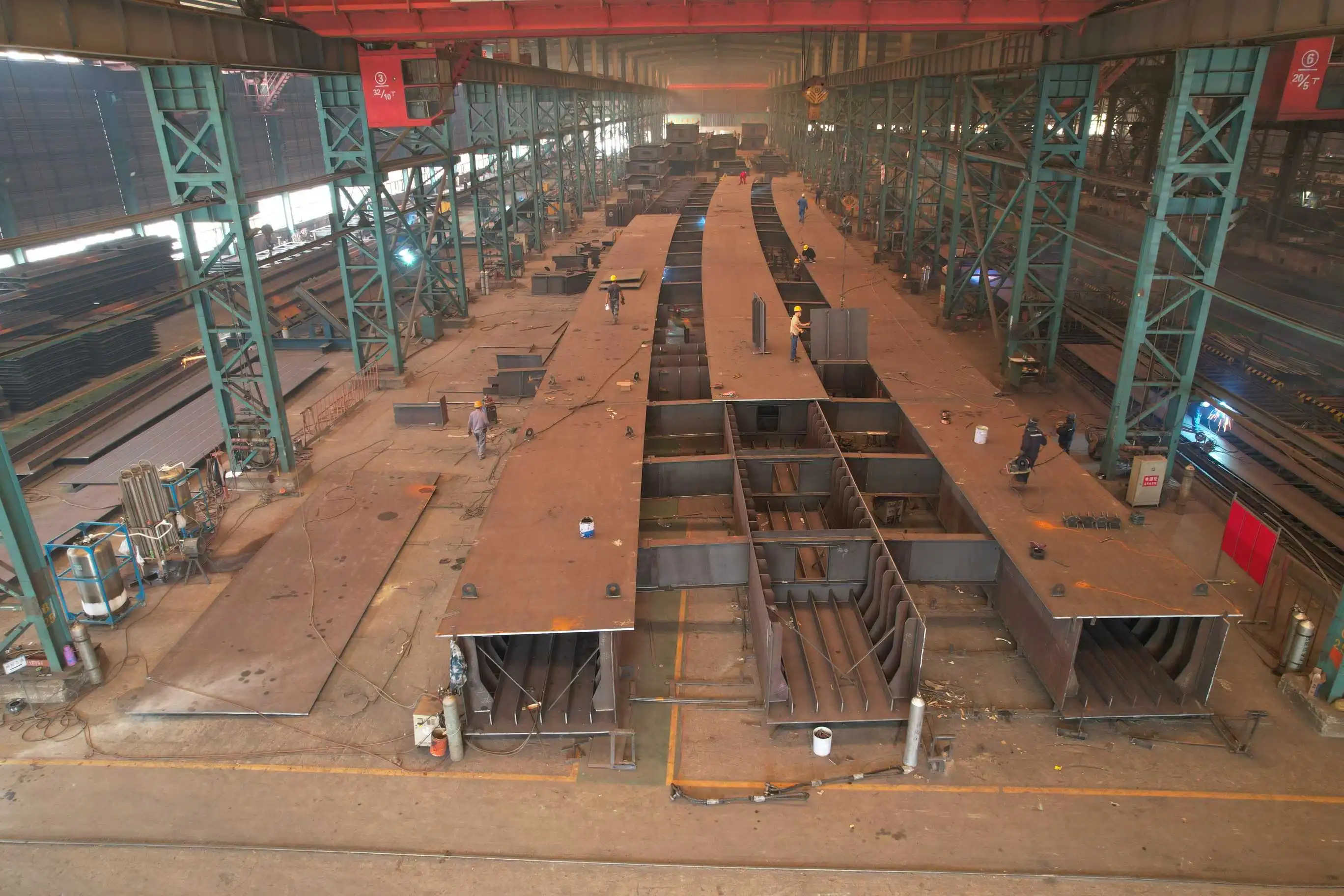

Factory Building Crane Steel Beam: Engineered for Strength and Precision

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading Factory Building Crane Steel Beam manufacturer and supplier. Our advanced production capabilities and commitment to quality make us the preferred choice for industrial and construction professionals worldwide.

Product Description:

Our products are engineered to meet the demanding requirements of modern industrial facilities. Crafted from high-grade Q235B/Q345B I-beam steel, these beams offer exceptional strength and durability. With flange widths ranging from 100-300mm and web thicknesses of 6-20mm, our crane beams are designed to support loads of 5-50 tons. The addition of stiffeners on the upper flange enhances load-bearing performance, ensuring safety and reliability in your factory operations.

Product Features:

- Customizable dimensions to suit your specific project needs

- Enhanced load-bearing capacity with upper flange stiffeners

- Compatible with standard crane rail installation systems

- Fatigue strength of ≥2×10^6 cycles for long-term reliability

- 20% more cost-effective than traditional welded H-beams

Factory Building Crane Steel Beam

Quality Control:

At Zhongda, we prioritize quality at every stage of production. Our Factory Building Crane Steel Beam undergo rigorous testing and inspection processes, including non-destructive testing and precision measurements. We adhere to international standards, including ISO 9001, to ensure consistently high-quality products that meet or exceed industry expectations.

Why Choose Us?

- Vertically integrated capabilities from R&D to installation

- State-of-the-art manufacturing facilities with 60,000-ton annual capacity

- Expertise in complex project execution and BIM-based design

- 70% client retention rate and 20-30% reduced lead times

- Compliance with global standards including EN 1090, AWS, and JIS

Production Process:

Our streamlined production process is the cornerstone of our high - quality output. It commences with CNC ultra - thick plate cutting, where our advanced machines precisely slice through thick materials, setting the foundation for accurate manufacturing. Next, the 3 - axis CNC drilling system takes over, creating holes with pinpoint accuracy, crucial for seamless component integration. Automated welding then efficiently joins parts, delivering consistent, robust welds. This integrated approach ensures precision and efficiency in every product we produce, meeting the most demanding industry standards.

OEM & ODM Services:

We offer comprehensive OEM and ODM services for the products, tailored to your specific requirements:

- Material Customization: Choose from Q235B or Q345B steel grades

- Size Specifications: Customize flange width and web thickness

- Load Capacity: Beams designed for 5-50 ton crane systems

- Special Features: Optional rail clamp bolt holes for easy installation

- Rapid Turnaround: 15 days for standard specs, 25 days for custom designs

- Quality Assurance: 15-year warranty on all products

Our engineering team works closely with clients to develop solutions that optimize performance and cost-effectiveness for your unique factory building needs.

Project Cases:

Our products have been successfully implemented in numerous high-profile projects:

- Shenyang Heavy Machinery Plant: Supplied 10,000 tons of crane beams for a new production facility, reducing installation time by 25%.

- Liaoning Automotive Assembly Plant: Provided custom 40-ton capacity crane beams, increasing operational efficiency by 30%.

- International Steel Mill Expansion: Delivered 5,000 tons of crane beams meeting EN 1090 standards for a global client's facility upgrade.

Certifications:

Our products are CE certified and comply with FEM 1.001 Crane Rail Standards, ensuring global acceptance and regulatory compliance.

Packaging and Delivery:

We offer secure packaging solutions and flexible delivery options to meet your project timelines, with door-to-door service available for international clients.

FAQ:

Q: What is the lead time for custom products?

A: Standard specifications are ready in 15 days, while custom designs typically take 25 days.

Q: Can you provide technical support for installation?

A: Yes, our experienced team offers comprehensive technical support and on-site assistance if required.

Q: Are your products suitable for seismic zones?

A: Absolutely. We can design beams to meet specific seismic requirements for your location.

Contact Us:

Ready to elevate your factory building project with our superior Factory Building Crane Steel Beam? Contact our expert team at Ava@zd-steels.com for a personalized quote and technical consultation.

YOU MAY LIKE