2. Certifications: CE, EN 10025. Seismic design verification report for earthquake - resistance.

3. Custom services: Supports column combinations, customizable galvanized anti - corrosion.

4. Delivery: Standard 20 days, special anti - corrosion +5 days.

5. Applications: Deep foundation pit supports, high - rise building columns. Axial load capacity ≥2000kN.

6. Cost: Saves 52% construction time vs. concrete. Modular design cuts installation costs.

Factory Building Bracing Lattice Column: Robust Support for Industrial Structures

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading Factory Building Bracing Lattice Column manufacturer and supplier. Our advanced products offer superior strength, durability, and cost-effectiveness for large-scale industrial projects.

Product Description

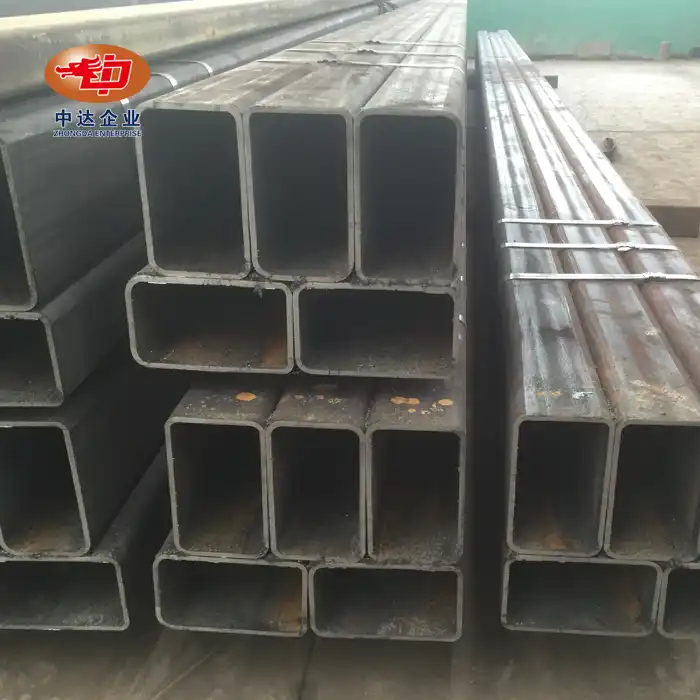

Our products are engineered to provide exceptional structural support for factory buildings, warehouses, and industrial facilities. These columns combine high load-bearing capacity with efficient material usage, making them ideal for projects requiring both strength and economy. Each product is precision-manufactured using Q355B steel, ensuring optimal performance in demanding industrial environments.

Product Features

- Customizable cross-section height (200-600mm) for versatile applications

- Lacing plate spacing ≤500mm for enhanced stability

- Available in double-limb and quadruple-limb configurations

- Axial load capacity ≥2000kN, suitable for high-rise structures

- Galvanized anti-corrosion treatment options for extended lifespan

Quality Control

Our Factory Building Bracing Lattice Columns undergo rigorous quality control processes, including:

- Non-destructive testing to ensure structural integrity

- Compliance with ISO 9001/14001/45001 standards

- Seismic design verification for earthquake-resistant performance

- Strict adherence to EN 10025 and CE certification requirements

Why Choose Us?

- Industry-leading R&D capabilities and proprietary technologies

- 60,000-ton annual production capacity for large-scale orders

- BIM-based digital design for precision and efficiency

- 20-30% reduced lead times compared to industry standards

- Proven track record with 60+ landmark projects and 70% client retention rate

Production Process

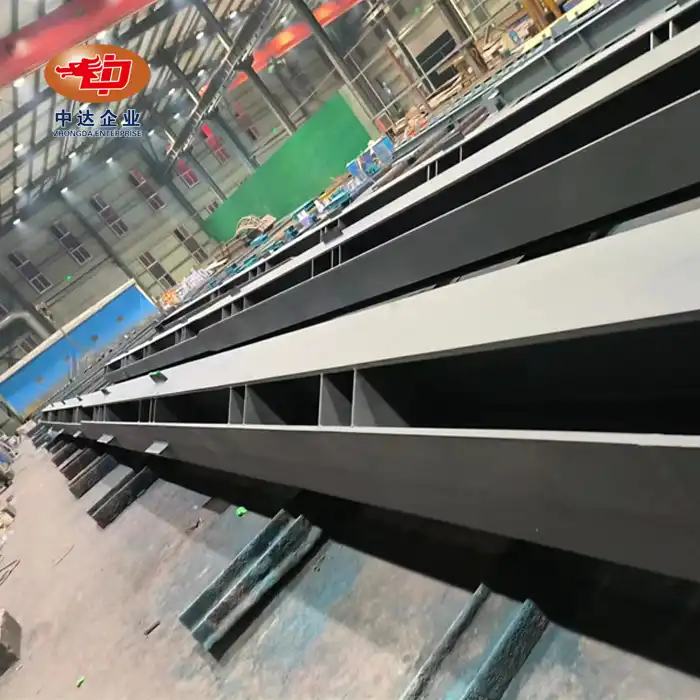

Our state-of-the-art facility is equipped with advanced CNC machinery that delivers unparalleled precision in cutting, shaping, and drilling, ensuring every product meets exact specifications. Automated welding lines enhance efficiency and consistency, reducing production time while maintaining high-quality joints and assemblies. Additionally, our facility features a 50-ton crane capacity, enabling the handling of large and heavy components with ease. Together, these technologies create a streamlined, efficient production process that guarantees top-tier quality, reliability, and performance in every product we manufacture, meeting the needs of even the most demanding projects.

OEM & ODM Services

We offer comprehensive OEM and ODM services for the products, tailored to your specific project requirements:

- Customizable material specifications, including Q355B steel and various lacing plate options

- Flexible column combinations, supporting both double-limb and quadruple-limb designs

- Specialized corrosion protection treatments for harsh environments

- Rapid turnaround times: 20 days for standard specifications, with only 5 additional days for special anti-corrosion treatments

- Modular designs to reduce installation costs and construction time by up to 50% compared to traditional concrete structures

Our engineering team works closely with clients to optimize product designs for specific load requirements, site conditions, and local building codes.

Project Cases

Our products have been successfully implemented in numerous high-profile projects, including:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion

- Multiple industrial plants for China Railway, CSCEC, and CCCC

- Overseas equipment components for Australian mining crushing stations

These diverse applications showcase the versatility and reliability of our products across various industrial and infrastructure projects.

Project Cases

Certifications

Our products are certified to meet EN 1090, AWS, and JIS standards, which are globally recognized benchmarks for quality, safety, and performance in construction and manufacturing. This ensures full compliance with international regulations, making our materials readily acceptable across different markets. The certifications also facilitate seamless integration into international EPC (Engineering, Procurement, and Construction) project chains, allowing for smooth collaboration with global partners. By adhering to these rigorous standards, we provide reliable, high-quality products that meet the diverse needs of complex, multinational projects with confidence and efficiency.

Packaging and Delivery

We provide secure packaging and efficient logistics solutions for the products, with flexible shipping options to meet your project timelines and requirements.

FAQ

Q: What is the typical lead time for the products?

A: Standard specifications are typically ready in 20 days, with an additional 5 days for special anti-corrosion treatments.

Q: Can you provide custom designs for specific load requirements?

A: Yes, our engineering team can customize products to meet your exact specifications and local building codes.

Contact Us

Ready to optimize your industrial construction project with our Factory Building Bracing Lattice Columns? Contact our expert team at Ava@zd-steels.com for personalized assistance and quotations.

YOU MAY LIKE