2. Certifications: CE, compliant with EN 10025 - 4.

3. Customization: Honeycomb Beam Hole Design, reduces self - weight by 20%.

4. Delivery: Standard sizes in 15 days, non - standard in 25 days.

5. Application: High - rise building columns, industrial supports, 40% more lateral stiffness.

6. Cost: 10% material savings vs box columns, 31% more installation efficiency.

Double H-Section Cross-Section Column: Engineered for Strength and Efficiency

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Double H-Section Cross-Section Columns. Our advanced production capabilities, rigorous quality control, and innovative design solutions make our products the preferred choice for large-scale construction projects worldwide.

Product Description

Our products are the cornerstone of modern structural engineering. Designed for superior load-bearing capacity and structural integrity, these columns are ideal for high-rise buildings, industrial facilities, and heavy-duty support structures. The unique double H-shape provides enhanced stability and lateral stiffness, making them perfect for projects requiring exceptional strength and durability.

Key features of our products include:

- Material: High-quality Q355B low-alloy steel

- Flange Width: Customizable from 100-300mm

- Web Thickness: Ranging from 6-25mm

- Improved Lateral Stiffness: Up to 40% compared to standard columns

- Weight Reduction: Optional honeycomb beam hole design reduces self-weight by 20%

Double H-Section Cross-Section Columns

.

Quality Control

At Zhongda, quality is paramount. Our Double H-Section Cross-Section Columns undergo rigorous testing and inspection processes, including:

- Non-destructive testing

- Dimensional accuracy checks

- Material composition analysis

- Load-bearing capacity tests

We adhere to international standards, ensuring our columns meet or exceed industry specifications.

Why Choose Us?

- Expertise: With over 60 landmark projects completed, we bring unparalleled experience to your construction needs.

- Innovation: Our R&D-driven approach ensures cutting-edge solutions for your most challenging projects.

- Customization: We offer tailored designs to meet your specific project requirements.

- Cost-Efficiency: Our columns provide material cost savings of up to 10% compared to box columns.

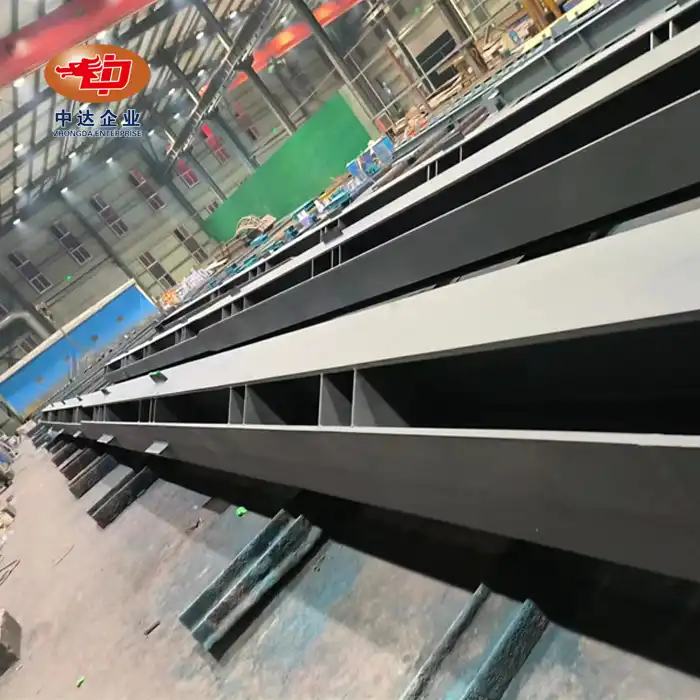

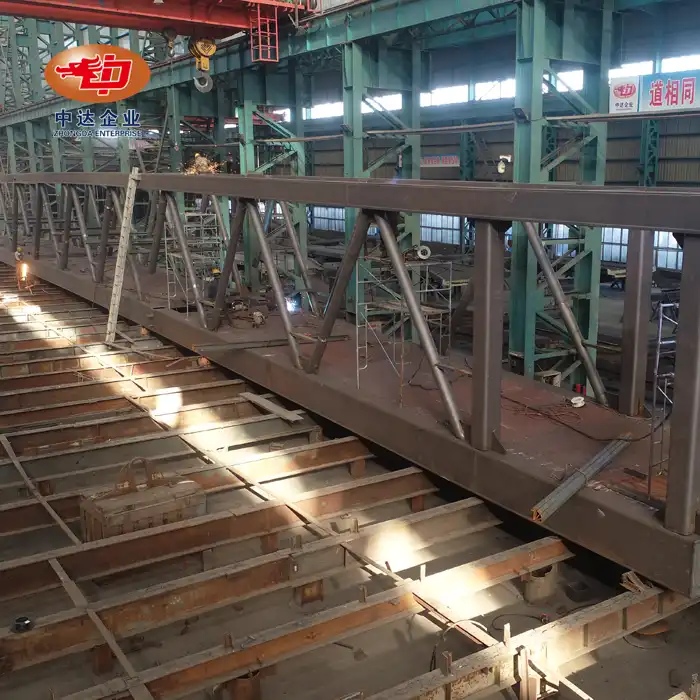

Production Process

Our state - of - the - art facility represents the pinnacle of modern manufacturing innovation. Inside, a range of advanced CNC machinery hums with precision, capable of intricate cuts and shaping on various materials. Automated welding lines seamlessly join components, providing consistent and robust welds, free from human error. Complemented by precision fabrication techniques, every detail of our products is meticulously crafted. This comprehensive setup, under the watchful eyes of our skilled technicians, ensures that the products emerging from our facility are of the highest quality, meeting and exceeding industry standards.

OEM & ODM Services

We understand that every project is unique. That's why we offer comprehensive OEM and ODM services for our product. Our team of experienced engineers works closely with clients to develop custom solutions that meet specific project needs.

Customization options include:

- Tailored dimensions and specifications

- Specialized coatings for enhanced corrosion resistance

- Integration of additional structural elements

- Design optimization for improved performance and cost-efficiency

Our flexible production capabilities allow us to accommodate orders of varying sizes, from small specialized batches to large-scale project requirements.

Project Cases

Our products have been integral to numerous high-profile projects, including:

- The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Multiple industrial plants for leading manufacturing companies

- High-rise commercial buildings in major urban centers

- Heavy-duty support structures for international mining operations

These projects showcase our ability to deliver products that meet the most demanding structural requirements across diverse applications.

Cases

Certifications

Our products are CE certified and comply with EN 10025-4 standards. We also hold ISO 9001, ISO 14001, and ISO 45001 certifications, ensuring the highest quality and safety standards.

Packaging and Delivery

We ensure secure packaging to protect your products during transit. Standard sizes are typically delivered within 15 days, while custom designs may require up to 25 days.

FAQ

Q: What are the main advantages of the products?

A: They offer superior load-bearing capacity, enhanced lateral stiffness, and potential weight reduction, making them ideal for large-scale construction projects.

Q: Can you provide custom dimensions for the products?

A: Yes, we offer customization services to meet your specific project requirements.

Q: How do the products compare to traditional box columns?

A: They typically offer improved structural performance and can result in material cost savings of up to 10%.

Contact Us

Ready to elevate your construction project with our Double H-Section Cross-Section Columns? Contact us at Ava@zd-steels.com for a consultation and quote today.

YOU MAY LIKE