2. Certifications: ASTM A500 Grade C, suitable for North American market.

3. Customization: Holing, cutting, flange welding for modular construction.

4. Delivery: In - stock items in 2 days, custom specs in 20 days.

5. Application: Light industrial columns, warehouse shelving, compressive strength ≥235MPa.

6. Anti - corrosion: Hot - dip galvanizing (zinc layer ≥82μm), epoxy zinc - rich primer.

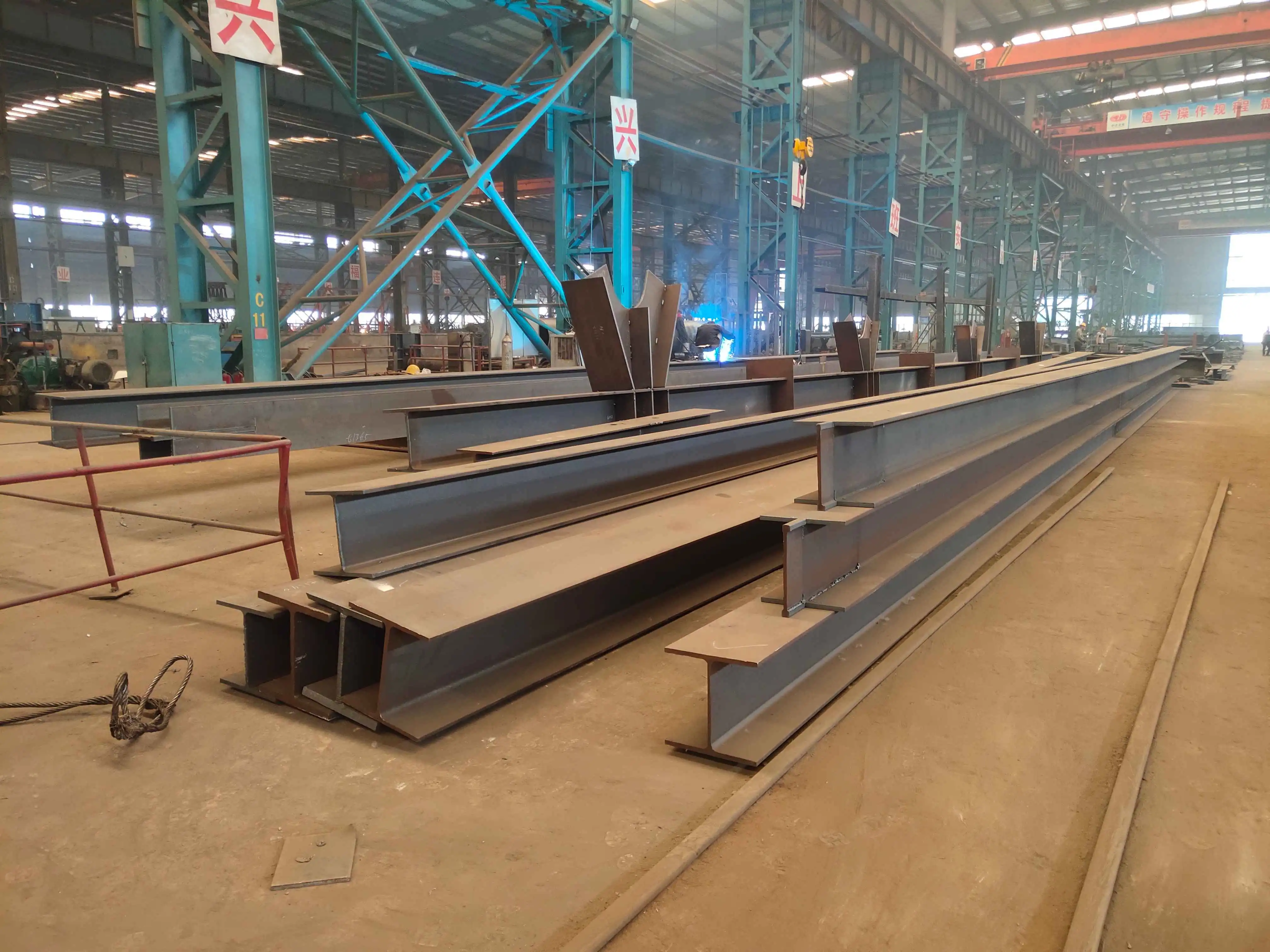

Square Tube Column for Industrial Factory Buildings: Shenyang Zhongda Steel's Premium Solution

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Square Tube Column for Industrial Factory Buildings. Our advanced manufacturing capabilities, rigorous quality control, and commitment to innovation make our square tube columns the preferred choice for industrial construction projects worldwide.

Product Description: Square Tube Column for Industrial Factory Buildings

Our products combines strength, durability, and versatility to meet the demanding requirements of modern industrial construction. Engineered with precision, these columns provide exceptional load-bearing capacity and structural integrity, ensuring the longevity and safety of your factory buildings.

Key features of our products include:

- High-strength steel composition (Q235B, Q345B)

- Wide range of dimensions (50x50mm to 400x400mm)

- Customizable wall thickness (2-16mm)

- Corrosion-resistant coatings available

- Compliant with international building codes

Square Tube Column for Industrial Factory Buildings

Quality Control

At Shenyang Zhongda Steel, we maintain stringent quality control measures for our products:

- Advanced non-destructive testing techniques

- ISO 9001:2015 certified quality management system

- Rigorous material inspections and dimensional checks

- Continuous monitoring throughout the production process

Why Choose Us?

When you select our Square Tube Column for Industrial Factory Buildings, you benefit from:

- 60,000-ton annual production capacity

- Customization options to meet specific project requirements

- Technical support from our experienced engineering team

- Competitive pricing and reliable delivery schedules

- Proven track record in large-scale industrial projects

Production Process

Our state-of-the-art facility utilizes advanced equipment for precision fabrication:

- CNC cutting and drilling utilize advanced computer - controlled machinery for highly accurate and efficient shaping of various materials.

- Automated welding lines employ robotic arms and state - of - the - art equipment to create strong, consistent welds with minimal human intervention.

- Surface treatment and coating application involve processes like sandblasting, painting, and plating to enhance appearance and durability.

OEM & ODM Services

Shenyang Zhongda Steel offers comprehensive OEM and ODM services for the products. We understand that every industrial project has unique requirements, and our team is equipped to deliver tailored solutions.

Our OEM & ODM capabilities include:

- Custom dimensions and specifications

- Material selection optimization

- Specialized coatings and finishes

- Integration of additional features (e.g., pre-drilled holes, welded connections)

- Design assistance and structural analysis

- Prototype development and testing

By choosing our OEM & ODM services, you ensure that your products perfectly aligns with your project's specific needs, potentially reducing installation time and overall costs.

Project Cases

Our products have been successfully implemented in numerous high-profile projects:

- Shenyang Automotive Manufacturing Plant: 20,000 square meters

- Dalian Petrochemical Complex: Custom corrosion-resistant columns

- Beijing Electronics Industrial Park: Modular construction system

- Tianjin Logistics Center: High-load capacity warehouse structure

These projects showcase our ability to deliver products for diverse industrial applications, consistently meeting or exceeding client expectations.

Certifications

Our products are certified to:

- ISO 9001:2015

- CE marking (EN 1090)

- ASTM A500 Grade C

Packaging and Delivery

- Secure bundling and shrink - wrapping are employed using high - quality materials to safeguard products during transit, preventing any potential damage.

- Custom crating available for international shipments is designed to meet specific requirements, ensuring safe delivery across long - distance hauls.

- Typical lead time: 2 - 3 weeks for standard orders. This allows for efficient processing while maintaining high - quality production standards.

FAQ

Q: What is the maximum load-bearing capacity of your products?

A: The load-bearing capacity varies based on dimensions and specifications. Our engineering team can provide detailed calculations for your specific requirements.

Q: Do you offer galvanized products?

A: Yes, we offer hot-dip galvanization and other corrosion-resistant coatings to suit various environmental conditions.

Q: Can you provide structural design services for our factory building project?

A: Absolutely. Our experienced engineers can assist with structural design optimization using your products.

Contact Us

Ready to elevate your industrial construction project with our premium Square Tube Column for Industrial Factory Buildings? Contact our sales team at Ava@zd-steels.com or call +86-24-25855668 for a personalized quotation and expert consultation.

YOU MAY LIKE