2. Certifications: API 5L anti - corrosion. Suitable for chemical & coastal areas.

3. Custom services: Surface treatments, flange connection nodes for assembly.

4. Delivery: In - stock within 3 days, custom 25 days.

5. Applications: Oil platform supports, bridge cable towers. Compressive strength ≥345MPa.

6. Advantage: Gas - shielded welding for seams reduces residual stress by 31%.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Bridge Bracing Circular Tube Column Manufacturer

As a leading Bridge Bracing Circular Tube Column manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled quality and expertise. Our advanced manufacturing capabilities, rigorous quality control, and commitment to innovation make us the top choice for your bridge construction needs.

Product Description: Bridge Bracing Circular Tube Column

Our products are engineered to provide superior strength and stability for large-scale bridge projects. Made from high-grade ASTM A500 seamless steel pipe, these columns offer exceptional durability and load-bearing capacity. Available in diameters ranging from 114mm to 508mm and wall thicknesses of 5-30mm, our circular tube columns can be customized to meet your specific project requirements.

Key features of our products include:

- High compressive strength (≥345MPa)

- Excellent corrosion resistance

- Versatile application in various bridge designs

- Customizable dimensions and surface treatments

- Easy assembly with optional flange connection nodes

Bridge Bracing Circular Tube Column

Quality Control

At Zhongda, we maintain the highest level of quality control throughout our production process. Our state-of-the-art facilities, equipped with advanced CNC ultra-thick plate cutting and automated welding lines, enable us to achieve unrivaled precision in manufacturing. This precision is further enhanced by our team of highly skilled technicians who are trained to operate these complex machines with utmost care. We also employ a range of advanced non-destructive testing methods, such as ultrasonic and radiographic testing, to detect any potential flaws. Adhering strictly to international standards like ISO 9001, we are committed to delivering products of the highest quality, ensuring our customers' satisfaction and trust.

Why Choose Us?

- Full-chain technical integration

- R&D-driven innovation

- Proven track record in mega-projects

- Customization capabilities

- Compliance with global standards (EN 1090, AWS, JIS)

- Expertise in weathering steel applications

- BIM-based digital design and lifecycle management

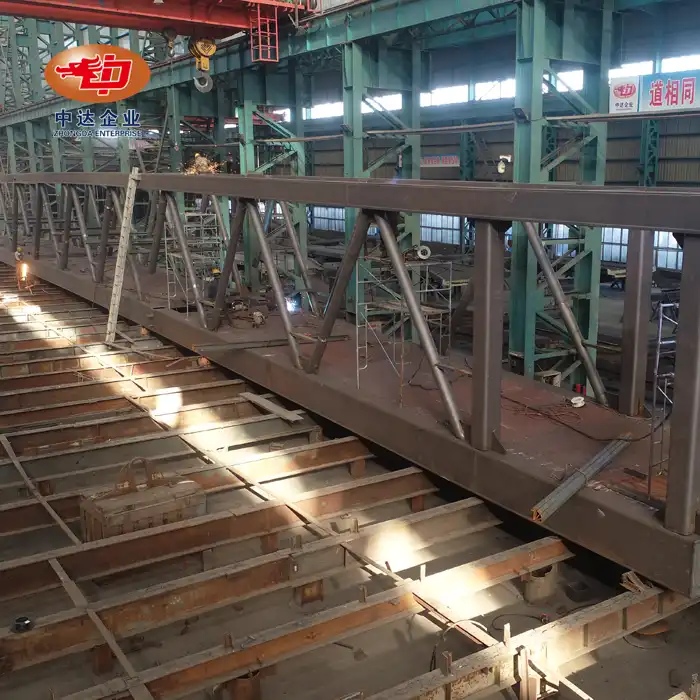

Production Process

Our Bridge Bracing Circular Tube Columns undergo a meticulous production process:

- Material selection

- Precision cutting and shaping

- Gas-shielded welding (reducing residual stress by 30%)

- Quality inspection

- Surface treatment (hot-dip galvanizing or spray coating)

OEM & ODM Services

Zhongda offers comprehensive OEM and ODM services for the products. We work closely with clients to develop tailored solutions that meet specific project requirements. Our experienced engineering team can assist with design optimization, material selection, and custom specifications. Whether you need specialized surface treatments, unique connection designs, or integration with other structural elements, we have the expertise to deliver.

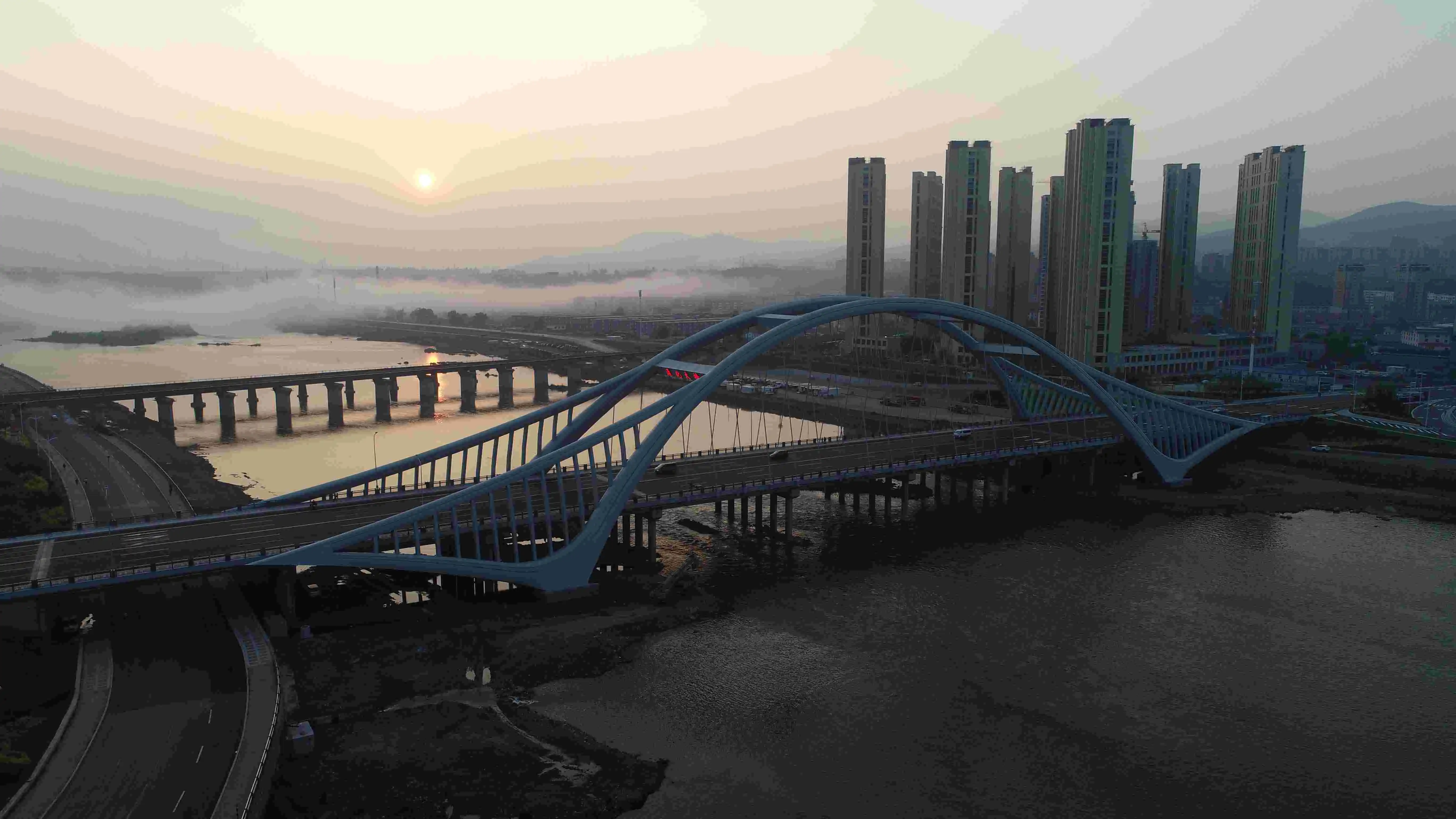

Project Cases

Our products have been successfully implemented in numerous high-profile projects:

- Shenyang Dongta Cross-Hunhe River Bridge (18,000-ton steel structure)

- Jingha Expressway expansion

- Multiple projects for China Railway, CSCEC, and CCCC

- International projects including Australian mining crushing stations

These case studies demonstrate our ability to handle complex, large-scale bridge construction projects with precision and efficiency.

Certifications

Our productns are certified to meet:

- API 5L Anti-Corrosion standards

- ISO 9001/14001/45001

- Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery

At our company, we prioritize the safety of your products during transit, which is why we ensure secure packaging. Our packaging team uses high - quality materials and innovative wrapping techniques to safeguard items from potential damage. For in - stock specifications, we pride ourselves on our rapid delivery service, with products dispatched within 3 days. In contrast, custom orders, which demand meticulous planning and specialized production, typically require a 25 - day lead time. This allows us to meet your unique requirements precisely and deliver a product that exceeds your expectations.

FAQ

Q: Can you provide the products for high-salt environments?

A: Yes, our columns are suitable for coastal and chemical industry applications, with specialized anti-corrosion treatments available.

Q: What is the minimum order quantity?

A: We can accommodate various order sizes. Please contact us for specific requirements.

Q: Do you offer technical support for installation?

A: Absolutely. Our team provides comprehensive technical support throughout the project lifecycle.

Contact Us

Ready to elevate your bridge construction project with our premium Bridge Bracing Circular Tube Columns? Contact us at Ava@zd-steels.com for a personalized quote and expert consultation.

YOU MAY LIKE