2. Certifications: CE, compliant with EN 10025 - 4.

3. Customization: Honeycomb Beam Hole Design, reduces self - weight by 20%.

4. Delivery: Standard sizes in 15 days, non - standard in 25 days.

5. Application: High - rise building columns, industrial supports, 40% more lateral stiffness.

6. Cost: 10% material savings vs box columns, 32% more installation efficiency.

Low-Alloy Steel Cross-Section Columns: Superior Strength and Durability

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Low-Alloy Steel Cross-Section Columns. Our advanced production capabilities and commitment to quality make us the preferred choice for construction firms and industrial equipment manufacturers worldwide. Zhongda's products offer unparalleled strength, durability, and cost-effectiveness for your large-scale projects.

Product Description

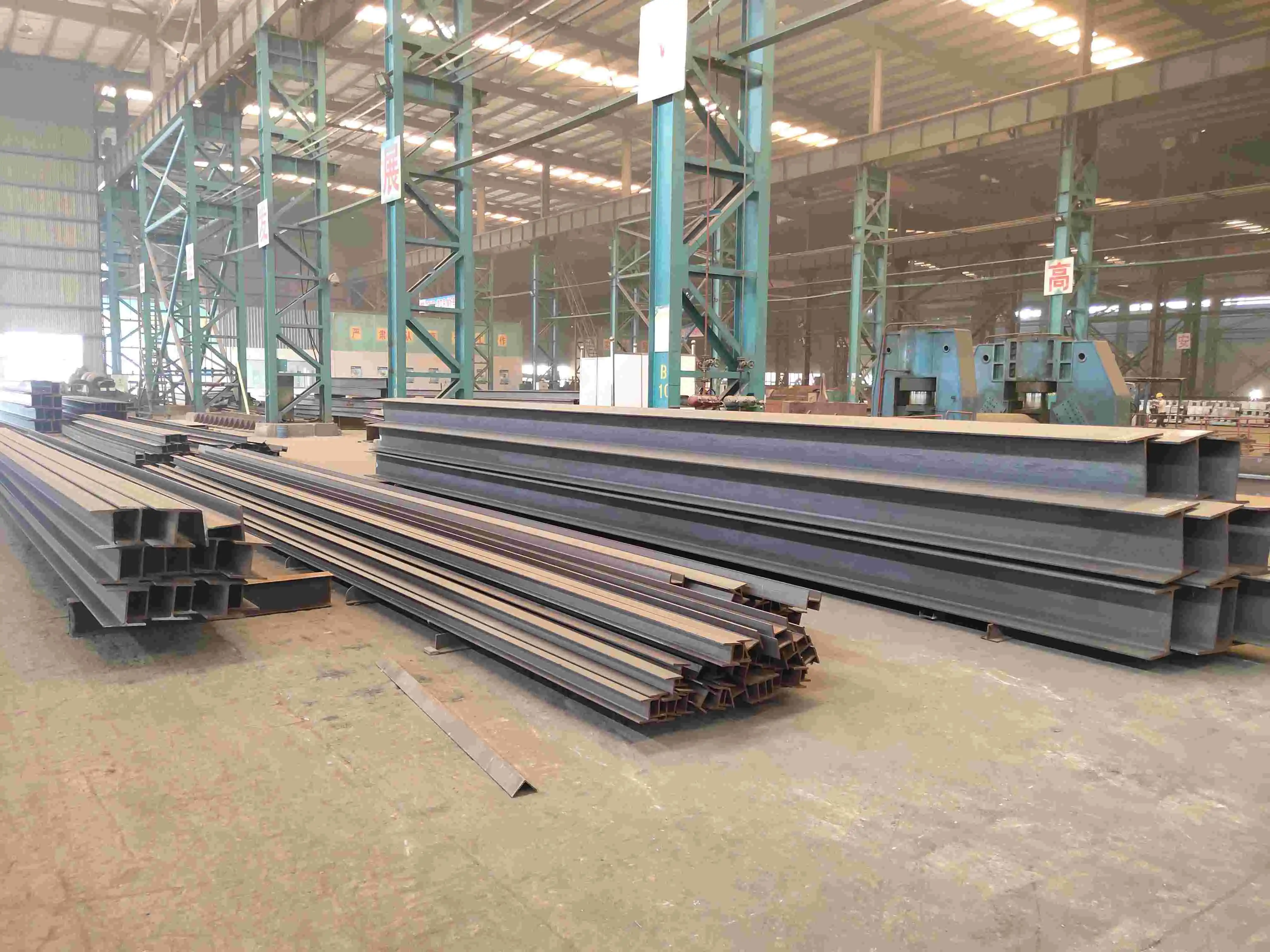

Our products are engineered to meet the demanding requirements of modern construction and industrial applications. Fabricated from high-quality Q355B low-alloy steel, these columns provide exceptional structural integrity and longevity. The double H-shaped steel welded assembly offers superior load-bearing capacity and resistance to deformation, making them ideal for high-rise buildings, bridges, and heavy industrial structures.

Key features of our products include:

- Flange width options ranging from 100mm to 300mm

- Web thickness varieties from 6mm to 25mm

- Customizable lengths to suit your project specifications

- Enhanced lateral stiffness, improved by 40% compared to traditional columns

- Reduced self-weight design options, decreasing overall structural load

Low-Alloy Steel Cross-Section Columns

Quality Control

At Zhongda, we maintain rigorous quality control measures throughout our production process. Our products undergo stringent testing and inspection, ensuring compliance with international standards such as EN 10025-4. With our ISO 9001:2015 certified quality management system, you can trust in the consistent excellence of our products.

Why Choose Us?

Selecting Zhongda for your productn needs means partnering with an industry leader. Our state-of-the-art facilities, including Northeast China's largest steel workshop and advanced CNC equipment, guarantee precision fabrication and timely delivery. With a 70% client retention rate and 20-30% lead time reduction, we're committed to your project's success.

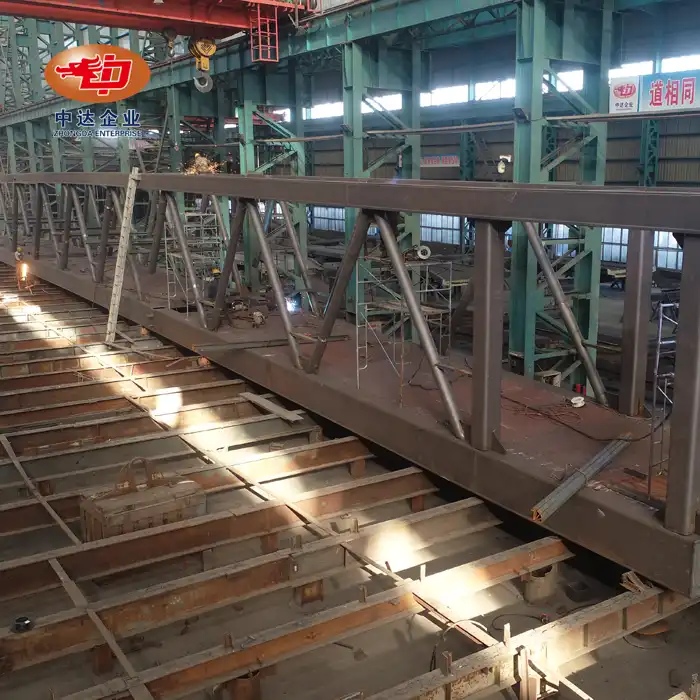

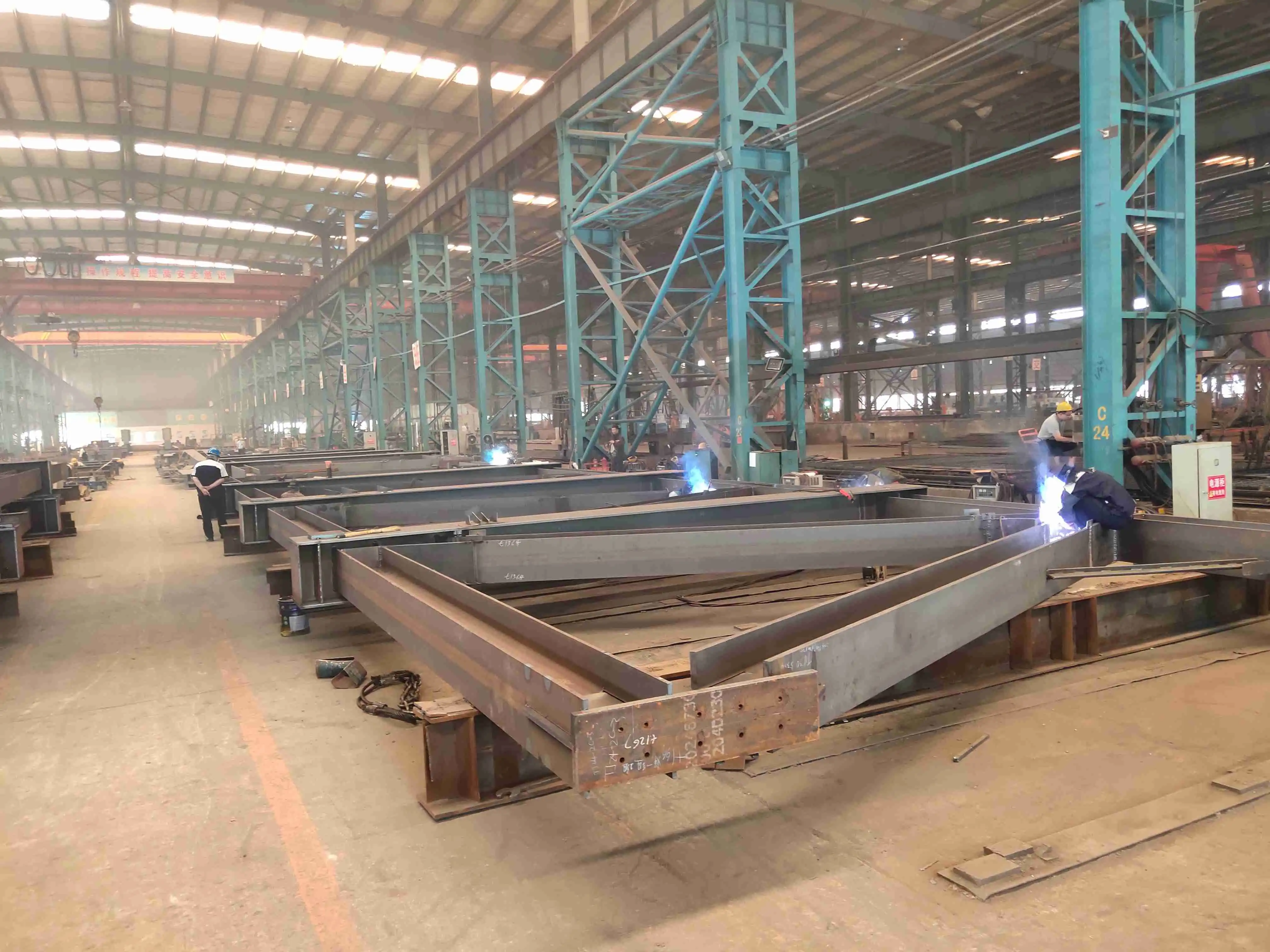

Production Process

Our streamlined production process includes:

- Material selection and testing

- CNC cutting and drilling

- Automated welding and assembly

- Non-destructive testing and quality inspection

- Surface treatment and finishing

OEM & ODM Services

Zhongda offers comprehensive OEM and ODM services for the products. We understand that each project has unique requirements, and our team of experienced engineers is ready to collaborate with you to develop customized solutions. Whether you need specialized honeycomb beam hole designs to reduce self-weight by 20% or specific material compositions to enhance performance, we've got you covered.

Our flexible manufacturing capabilities allow us to accommodate various specifications:

- Custom flange widths and web thicknesses

- Specialized surface treatments for corrosion resistance

- Integration of connection points for easy on-site assembly

- Tailored packaging for international shipping

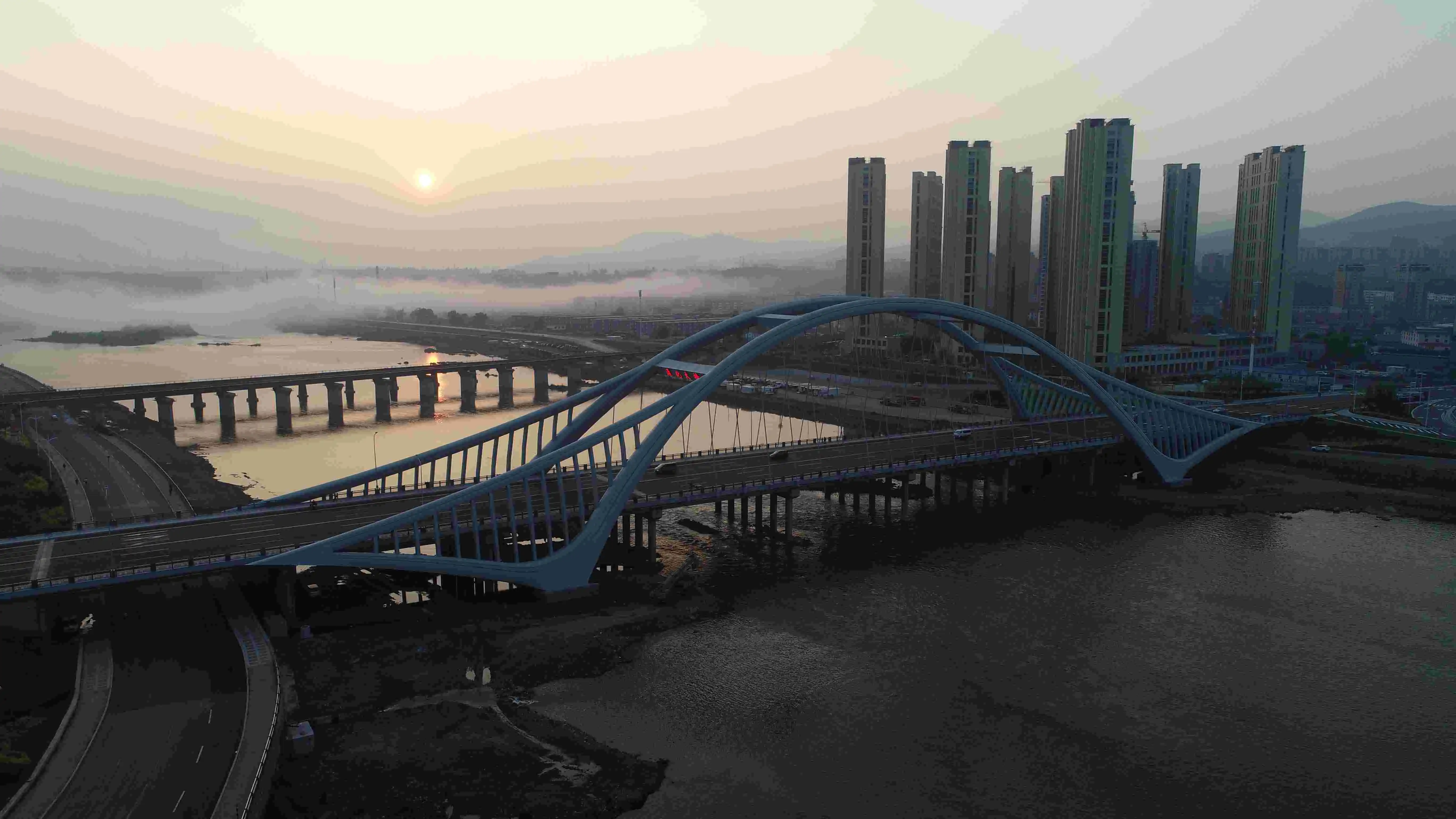

Project Cases

Our Low-Alloy Steel Cross-Section Columns have been successfully implemented in numerous high-profile projects:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge: Utilized our columns for superior strength in a challenging environment.

- Jingha Expressway expansion: Our columns provided the necessary support for increased traffic capacity.

- Australian mining crushing stations: Exported custom-designed columns to withstand extreme operational conditions.

These projects showcase our ability to deliver products for diverse applications across various industries and geographical locations.

Certifications

Our products are:

- CE Certified

- Compliant with EN 1090, AWS, and JIS standards

- Manufactured in ISO 9001/14001/45001 certified facilities

Packaging and Delivery

We ensure secure packaging for safe transportation. Standard sizes are typically delivered within 15 days, while custom designs may require up to 25 days. Our logistics team coordinates efficient shipping to meet your project timelines.

FAQ

Q: What are the advantages of the products over traditional columns?

A: Our products offer improved lateral stiffness, reduced material costs, and increased installation efficiency. They provide a 10% material cost saving compared to box columns and can increase installation efficiency by 30%.

Q: Can you provide technical support for integrating these columns into our project designs?

A: Absolutely! Our team of structural engineers is available to assist with technical specifications, load calculations, and integration strategies to optimize your project's performance.

Contact Us

Ready to elevate your construction projects with our superior Low-Alloy Steel Cross-Section Columns? Contact our sales team at Ava@zd-steels.com for personalized quotes, technical consultations, and to discuss how we can meet your specific project requirements.

YOU MAY LIKE