2. Material: Q355D steel pipe, 600 - 2500mm dia., 14 - 40mm thickness.

3. Seismic: Concrete - filled, ≤1/300 lateral displacement.

4. Anti - Corrosion: Arc - sprayed aluminum (150μm) + fluorocarbon topcoat (C5 - M).

5. Certifications: EN 1090 - 2 EXC4, UT inspection report.

6. Construction: Patented sleeve positioning, ±1mm accuracy.

7. Delivery: Standard in 30 days, complex in 45 days.

Curved Steel Tube Columns: Precision-Engineered Solutions for Modern Architecture

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Curved Steel Tube Column Manufacturer

At Shenyang Zhongda, we leverage our full-chain technical integration and R&D-driven standardization to deliver superior Curved Steel Tube Columns. Our ISO-certified facilities and advanced equipment ensure unparalleled quality and efficiency in every project.

Product Description

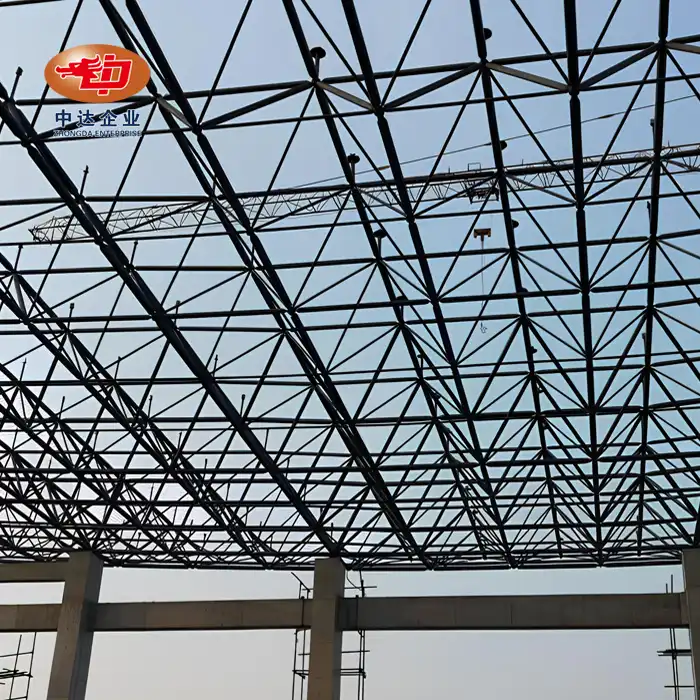

Our products are the cornerstone of innovative architectural design, offering both structural integrity and aesthetic appeal. These columns are precision-engineered using state-of-the-art 3D CNC pipe bending technology, guaranteeing an error margin of ≤2mm/m. We specialize in Q355D steel pipes with diameters ranging from 600-2500mm and wall thicknesses of 14-40mm, suitable for a variety of high-rise and complex structural applications.

Product Features

- Customizable curvature and dimensions to meet project-specific requirements

- High strength-to-weight ratio for optimal load-bearing capacity

- Seamless integration with concrete-filled steel tube composite structures

- Superior seismic performance with lateral displacement angle ≤1/300

- Weathering steel options for enhanced durability in challenging environments

Quality Control

Our rigorous quality assurance process includes:

- Non-destructive testing with UT inspection reports provided

- Compliance with EN 1090-2 EXC4 certification standards

- Arc-sprayed aluminum (150μm) + fluorocarbon topcoat (C5-M Grade) for exceptional corrosion resistance

- Continuous monitoring throughout the production process to ensure consistency

Why Choose Us?

- Industry-leading R&D capabilities and proprietary technologies

- Proven track record with over 60 landmark projects completed

- 70% client retention rate, demonstrating our commitment to customer satisfaction

- 20-30% lead time reduction compared to industry standards

- Comprehensive technical support and consultation services

Production Process

Our streamlined production process is a well - orchestrated symphony of craftsmanship and technology. It commences with precision cutting, where state - of - the - art machinery slices materials to exact dimensions. Bending follows, shaping components with utmost accuracy. Welding, executed by our skilled welders, creates strong and seamless joints. Finally, surface treatment adds a protective and aesthetic finish. Throughout, our expert team keeps a vigilant eye, monitoring each step to ensure that the highest quality standards are met, resulting in products that are both reliable and visually appealing.

OEM & ODM Services

We offer tailored OEM and ODM solutions to meet your specific project needs:

- Special-Shape Forming: Our advanced 3D CNC pipe bending technology supports spiral and wave shapes, allowing for unique architectural expressions.

- Material Customization: Beyond our standard Q355D steel, we can work with various steel grades and specifications to meet your project requirements.

- Anti-Corrosion Systems: We offer customized surface treatments, including our premium arc-sprayed aluminum with fluorocarbon topcoat for maximum durability.

- Design Collaboration: Our engineering team works closely with your architects and structural engineers to optimize designs for both aesthetics and performance.

- Patented Assembly Technology: Our sleeve positioning system ensures assembly accuracy of ±1mm, facilitating faster and more precise on-site construction.

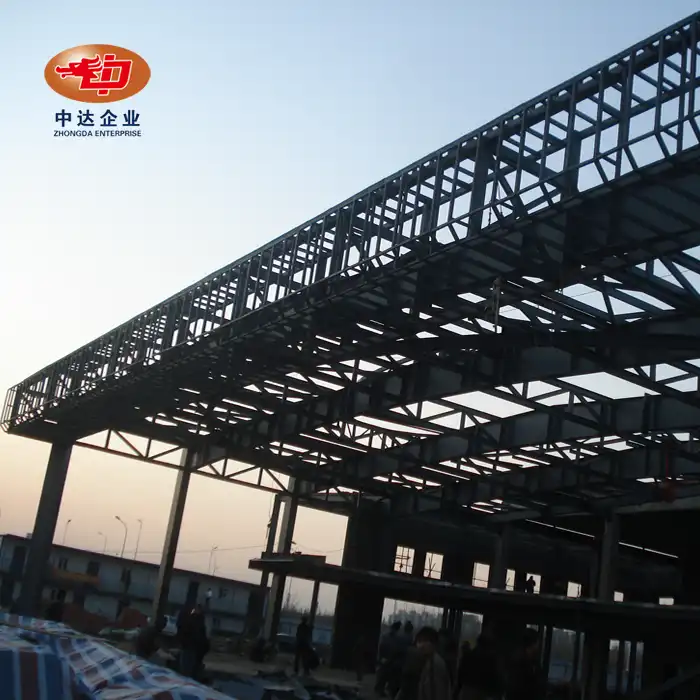

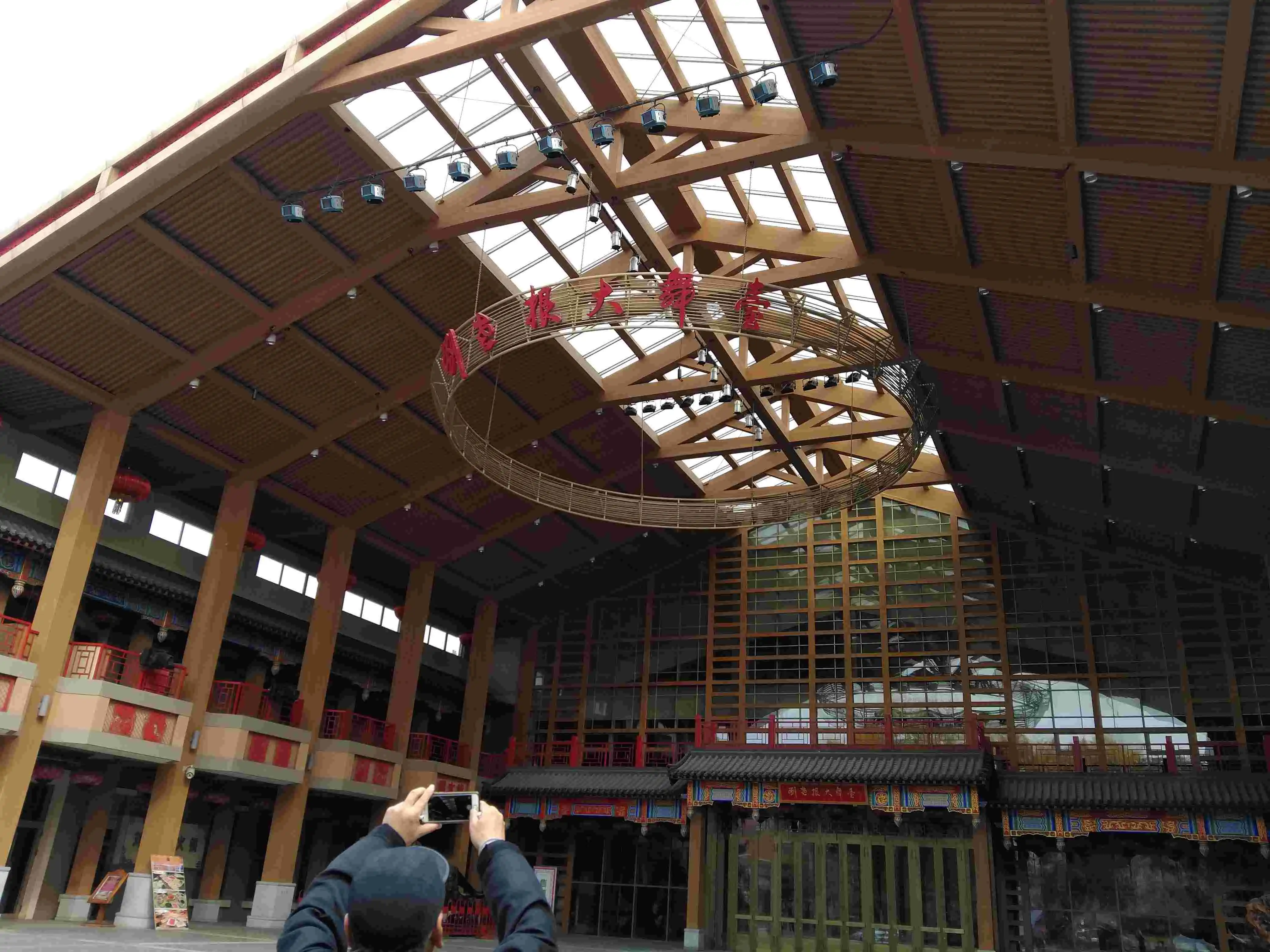

Project Cases

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge: Showcasing our expertise in large-scale, complex structural projects

- Australian Mining Crushing Stations: Demonstrating our global capabilities and compliance with international standards

- Modular Medical Facilities: Highlighting our innovative use of Curved Steel Tube Columns in prefabricated construction

Certifications

ISO 9001/14001/45001, EN 1090-2 EXC4, Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery

We ensure secure packaging and efficient logistics, with standard models delivered within 30 days and complex shapes within 45 days.

FAQ

Q: Can you customize products for specific architectural designs?

A: Absolutely! Our advanced 3D CNC technology allows us to create custom curvatures and shapes to match your unique design requirements.

Q: What are the advantages of using products in high-rise construction?

A: The products offer excellent strength-to-weight ratios, superior seismic performance, and aesthetic versatility, making them ideal for modern high-rise structures.

Contact Us

Ready to elevate your construction project with our premium Curved Steel Tube Columns? Contact our expert team at Ava@zd-steels.com for personalized consultation and quotes.

YOU MAY LIKE