2. Nodes: Bolt - sphere (Φ100 - 300mm), ≤2mm deviation.

3. Span: Single up to 120m, column - free.

4. Anti - corrosion: Anodizing (AA25) or fluorocarbon coating.

5. Certifications: ISO 9001, load test report.

6. Customization: Curved space frame (≥18m radius), ETFE membrane for light.

Lightweight Aluminum Alloy Space Frame: Innovative Structural Solutions by Shenyang Zhongda

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Lightweight Aluminum Alloy Space Frames. Our advanced technology and expertise in aluminum alloy structures offer unparalleled advantages in weight reduction, structural integrity, and customization for your most demanding projects.

Product Description

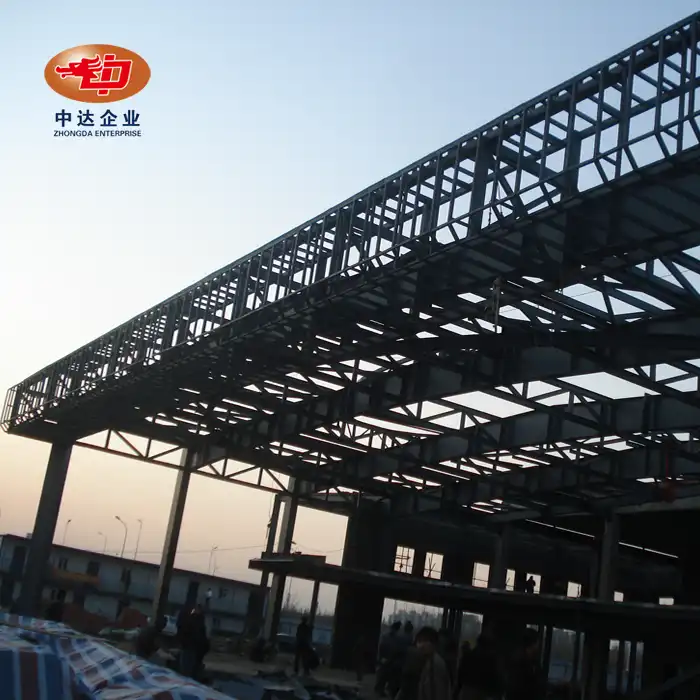

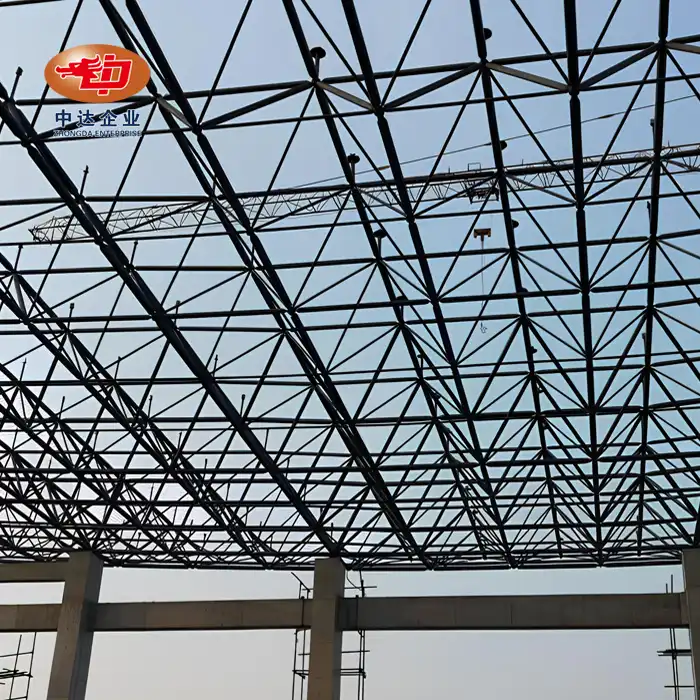

Our product represents the pinnacle of structural engineering innovation. Designed for industries demanding high performance and reduced weight, this versatile system utilizes 6061-T6 aluminum alloy components, offering a remarkable 55% weight reduction compared to traditional steel structures. The frame's bolt-sphere nodes (Φ100-300mm) ensure precise assembly with installation deviations of ≤2mm, guaranteeing structural stability and ease of construction. With single spans reaching up to 120m, our space frames provide column-free spaces ideal for large-scale automotive plants, aircraft hangars, and modern architectural marvels.

Product Features

- Ultra-lightweight design using 6061-T6 aluminum alloy

- Bolt-sphere node technology for precision assembly

- Large span capability up to 120m

- Superior corrosion resistance with anodizing (AA25 Grade) or fluorocarbon coating

- Customizable configurations, including curved designs (radius ≥15m)

- ETFE membrane covering option for enhanced light transmission

Quality Control

At Shenyang Zhongda, quality is paramount. Our Lightweight Aluminum Alloy Space Frames undergo rigorous testing and quality assurance processes. We utilize advanced non-destructive testing methods and maintain strict adherence to international standards. Our ISO 9001 certification and comprehensive load testing reports ensure that every frame meets the highest quality and safety standards demanded by our discerning clients in the automotive, aerospace, and construction sectors.

Why Choose Us?

Our expertise in R&D-driven standardization and core technologies sets us apart. We collaborate with top-tier design institutes and universities, leading industry standard development in aluminum alloy applications. Our BIM-based digital design and lifecycle management enhance complex project execution, providing you with innovative solutions that offer a competitive edge. With a 70% client retention rate and 20-30% lead time reduction, we're committed to your project's success.

Production Process

- Digital design and modeling

- Precision CNC fabrication

- Quality inspection

- Anti-corrosion treatment

- Pre-assembly testing

- Packaging and shipping

OEM & ODM Services

Our OEM and ODM capabilities are tailored to meet the unique needs of global wholesale buyers in automotive, aerospace, and construction industries. We offer comprehensive customization services, from conceptualization to final production. Our advanced R&D team can collaborate with your engineers to develop bespoke product solutions that align perfectly with your specific project requirements.

We excel in creating custom curved space frames with radii of curvature ≥15m, ideal for automotive showrooms or aircraft hangar designs. Our expertise in integrating ETFE membrane coverings enhances light transmission, perfect for energy-efficient building designs. Whether you need specialized node configurations for extreme load conditions or unique surface treatments for harsh environments, our OEM/ODM services ensure your vision becomes reality.

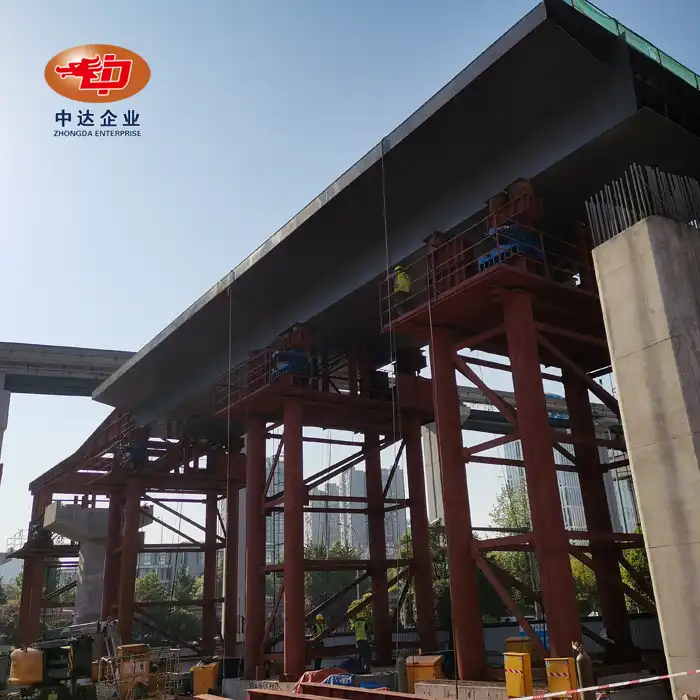

Project Cases

- Automotive: Designed and supplied a 100m-span product for an electric vehicle manufacturing plant, reducing construction time by 25% and improving energy efficiency.

- Aerospace: Developed a custom 80m-span frame with integrated support systems for a leading aircraft manufacturer's assembly facility, enhancing operational flexibility and reducing overall project costs by 15%.

- Construction: Engineered a curved 60m-span space frame with ETFE covering for a sustainable sports complex, increasing natural light penetration by 40% while maintaining structural integrity in high-wind conditions.

Certifications

- ISO 9001:2015 Quality Management System

- EN 1090 Execution of Steel Structures and Aluminium Structures

- AWS (American Welding Society) Certification

Packaging and Delivery

Our products are carefully packaged to ensure safe transportation. We offer flexible shipping options and can accommodate rush orders to meet your project timelines.

FAQ

Q: What is the maximum span achievable with your product?

A: Our standard designs can achieve single spans up to 120m, but we can engineer custom solutions for even larger spans based on specific project requirements.

Q: How does the weight of your aluminum space frame compare to steel alternatives?

A: Our products typically weigh 55% less than equivalent steel structures, offering significant advantages in transportation, handling, and reduced foundation loads.

Q: Can your space frames be used in corrosive environments?

A: Yes, our frames are treated with either anodizing (AA25 Grade) or fluorocarbon coating, providing excellent corrosion resistance suitable for various environmental conditions.

Contact Us

Ready to revolutionize your next project with our Lightweight Aluminum Alloy Space Frames? Contact our expert team at Ava@zd-steels.com for personalized consultation and quotations. Let's build the future together with Shenyang Zhongda's innovative structural solutions.

YOU MAY LIKE