Support Forms: Common forms include concentric bracing (such as cross bracing, single diagonal bracing, chevron bracing, etc.) and eccentric bracing. Concentric bracing has a simple structure and can effectively improve the lateral stiffness of the structure. Eccentric bracing, while ensuring a certain lateral stiffness, has better energy - dissipation capacity. Different forms are suitable for different structural types and force - bearing requirements.

Steel Selection: Structural steels such as Q235 and Q345 are mostly used to ensure that the steel has good strength, plasticity and toughness. According to the magnitude of the support force and the importance of the structure, the specific steel type and corresponding mechanical property indicators such as yield strength and tensile strength are determined.

Cross - sectional Dimensions: The bracing members generally use round steel, angle steel, channel steel or steel pipes, etc. Their cross - sectional dimensions are determined according to calculations and need to meet the requirements of strength, stability and stiffness. For example, in high - rise steel - structure buildings, due to the large wind load and earthquake action, the cross - sectional dimensions of the bracing members are relatively large.

Product Advantages

Enhanced Structural Stability: It effectively improves the lateral force - resistance ability of the structure, resists horizontal forces such as wind load and earthquake action, reduces the horizontal displacement and deformation of the structure, prevents the structure from being damaged due to excessive deformation, and ensures the safety and stability of the structure under various working conditions.

Improved Structural Mechanical Performance: Reasonably arranged bracings can adjust the force - transfer path of the structure, making the internal force distribution of the structure more uniform, avoiding local stress concentration, giving full play to the bearing capacity of each structural member, and improving the overall performance of the structure.

Increased Structural Energy - dissipation Capacity: For support forms with energy - dissipation mechanisms such as eccentric bracing, when disasters such as earthquakes occur, through the deformation and energy - dissipation of the bracing itself, it consumes the energy input into the structure, reduces the seismic response of the structure, and protects the main structure from severe damage.

Selling Points Concerned by Purchasers

Targeted Solutions: According to the specific structural type, function, site conditions and seismic fortification requirements of the purchaser's project, a personalized support design solution is provided to ensure that the support system is perfectly adapted to the overall structure and meets the specific needs of different projects.

Cost - effectiveness Balance: On the premise of ensuring structural safety and performance, by optimizing the support form and the cross - sectional dimensions of the members, the amount of steel used is reasonably controlled to reduce material costs. At the same time, the simple and efficient installation method can reduce construction time and labor costs, achieving a good balance between cost and benefit.

High-Quality Structure Bracing Solutions | Shenyang Zhongda Steel Structure Engineering Co., Ltd.

As a leading structure bracing manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers top-tier solutions for your construction needs. Our product frameworks provide numerous ventures the offer assistance and soundness they require. With more than 18 a long time of involvement, we offer high-quality items that meet worldwide measures by combining modern thoughts in plan with exact fabricating and dependable execution.

Product Description

Our product frameworks are designed to upgrade the soundness and load-bearing capacity of buildings and framework. These vital components convey strengths equally, minimizing basic stretch and guaranteeing long-term strength. We offer a wide range of bracing options, including:

- Cross bracing

- K-bracing

- V-bracing

- Diagonal bracing

Each sort is custom fitted to particular extend necessities, giving ideal bolster for different building plans. Our product is fabricated utilizing high-grade steel, guaranteeing remarkable quality and erosion resistance. The secluded plan permits for simple establishment and support, decreasing in general venture costs and timelines.

Why Choose Us?

At Shenyang Zhongda, we pride ourselves on conveying quality, unwavering quality, and development. Our product arrangements are sponsored by thorough quality control measures and broad testing. With a talented group of engineers and state-of-the-art generation offices, we ensure items that meet the most noteworthy industry measures.

Function & Application

Our product plays a vital role in construction by enhancing lateral stability and load distribution. Our bracing systems are ideal for:

- Commercial buildings

- Industrial facilities

- Bridges and overpasses

- Warehouses and storage facilities

- High-rise structures

By effectively transferring horizontal loads, our bracing ensures structural integrity even in challenging environments.

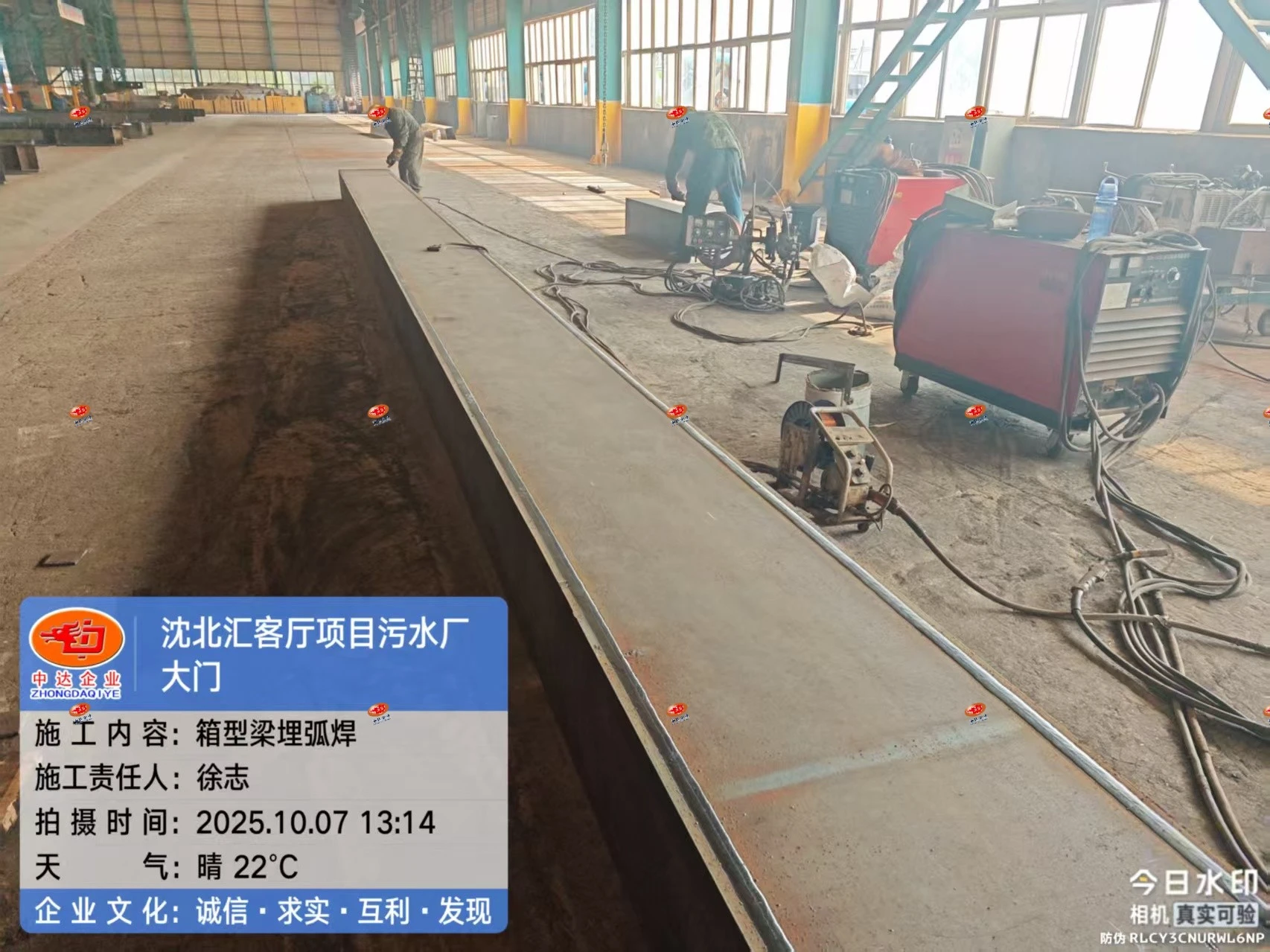

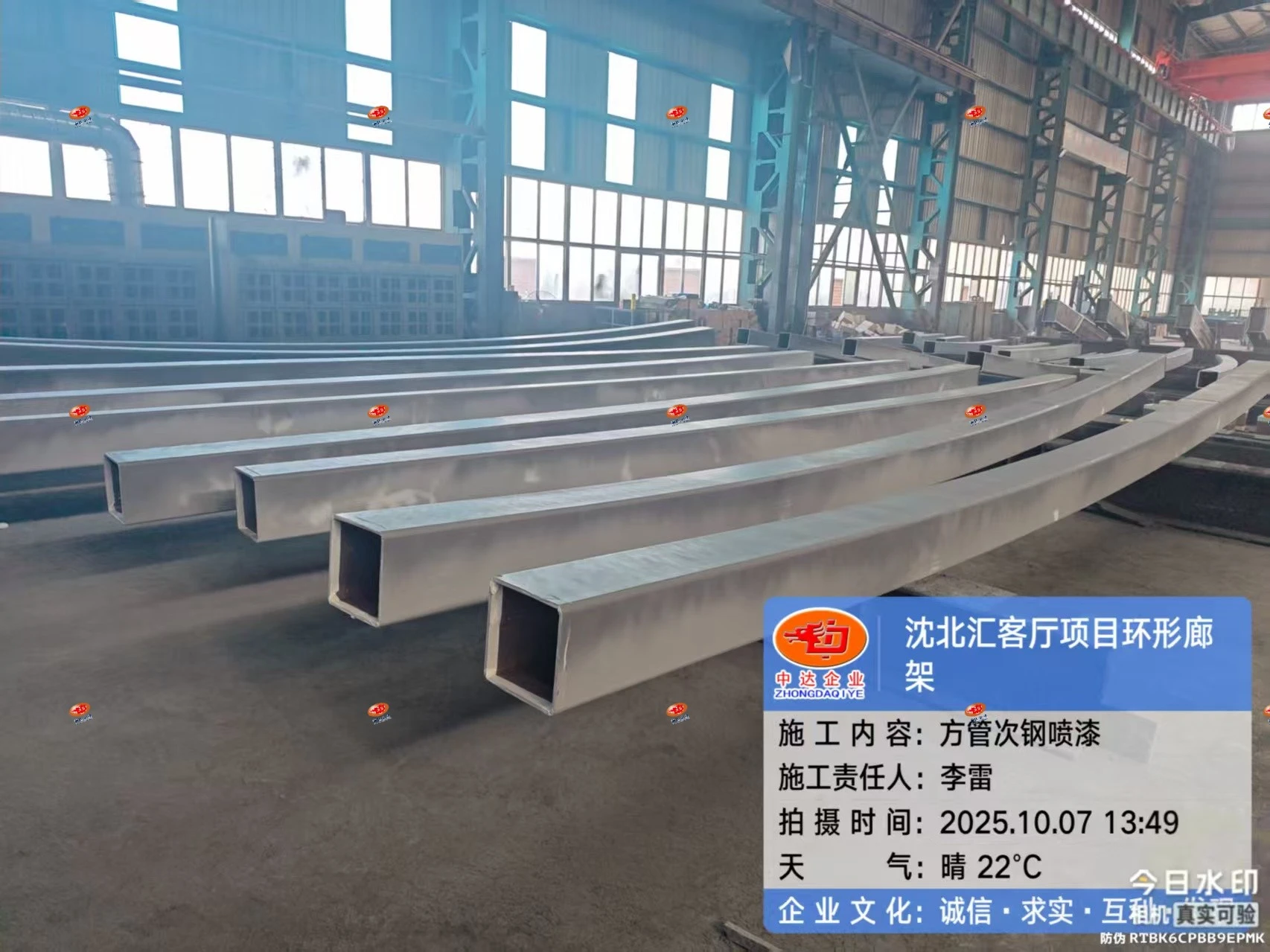

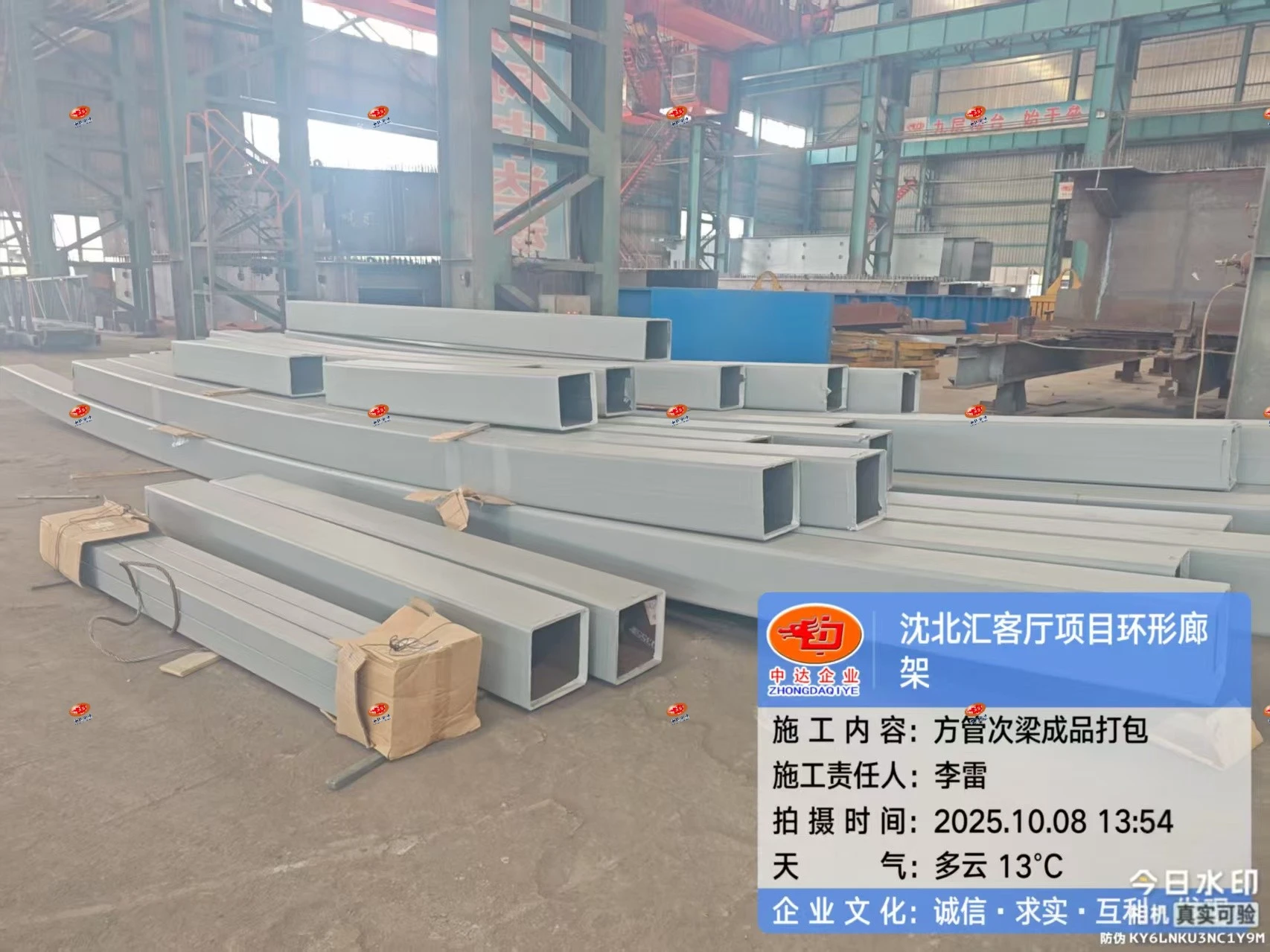

Production Process

Our structure bracing undergoes a meticulous production process:

- Design and engineering

- Material selection and cutting

- Precision fabrication

- Surface treatment and coating

- Quality inspection

- Packaging and shipping

Each step is carefully monitored to ensure consistent quality and performance.

OEM & ODM

We offer customized OEM and ODM services to meet your specific requirements. Our experienced team collaborates closely with clients to develop tailored product solutions. From concept to delivery, we ensure that every product aligns with your project specifications and industry standards.

Packaging and Delivery

Our product is securely packaged to prevent damage during transportation. We offer flexible shipping options to meet your project timelines and budget constraints.

Qualification of Company

Shenyang Zhongda Steel Structure Engineering Co., Ltd. holds the First-Class Steel Structure Engineering Qualification issued by China's Ministry of Housing and Urban-Rural Development. Our commitment to quality is further reinforced by ISO 9001:2015 certification and adherence to international standards such as ASTM and EN.

FAQs

- Q: What is the typical lead time for the product orders?

A: Lead times vary depending on order size and complexity, but we generally aim for 2-4 weeks for standard products. - Q: Can you provide custom product designs?

A: Yes, our engineering team can develop custom bracing solutions tailored to your specific project needs. - Q: What materials do you use for the product?

A: We primarily use high-strength steel alloys, but can accommodate other materials based on project requirements. - Q: Do you offer installation services for the product?

A: While we don't provide direct installation, we offer comprehensive technical support and guidelines for proper installation. - Q: How do you ensure the quality of your products?

A: We implement strict quality control measures throughout the production process and conduct rigorous testing before shipping.

Contact & Support

Ready to enhance your project with our premium structure bracing solutions? Contact our expert team today for personalized support and quotations. Let Shenyang Zhongda be your trusted partner in construction excellence.

Email: postmaster@zd-steels.com

YOU MAY LIKE

(1)_副本_1760321095013.jpg)