Area: Common prefabricated warehouses range in size from a few hundred to tens of thousands of square meters. The larger the area, the lower the cost per square meter. Generally, warehouses under 1,000 square meters will have higher costs per square meter.

Height: Cornice heights of 3-10 meters are common. Costs increase with each increase in height; for example, increasing from 6 meters to 8 meters could increase costs by 10%-20%.

Structural Type: Lightweight steel structures are relatively inexpensive and generally suitable for small warehouses with light loads. Heavyweight steel structures are used for large warehouses with high load-bearing requirements and are more expensive.

Cost Range

International Market: Based on a free on board (FOB) basis, prices range from approximately US$10-160 per square meter. The most common price range is US$25-70 per square meter.

Domestic Market: Generally speaking, the cost of a typical prefabricated steel warehouse is between RMB 800-2,000 per square meter. Light steel warehouses (under 10 meters) cost approximately 600-800 yuan per square meter, while those 10-12 meters cost approximately 750-1000 yuan per square meter. Heavy steel warehouses cost approximately 1500-2000 yuan per square meter.

Cost Advantages

Material Costs: Centralized prefabrication in the factory allows for bulk material procurement, reducing unit prices and minimizing material waste. A 10%-20% price discount is available for steel purchases reaching a certain scale.

Construction Costs: On-site installation is fast, reducing labor and equipment rental time. Compared to traditional construction methods, construction time can be shortened by 30%-50%, resulting in significant savings in labor and equipment rental costs.

Maintenance Costs: Prefabricated components offer consistent quality and durability, resulting in low ongoing maintenance costs. Roofing and wall materials have a long lifespan, requiring no major maintenance for 10-15 years, reducing maintenance costs by 30%-40% compared to traditional warehouses. Cost Key Points for Buyers

Customization Costs: Customization is possible based on buyer needs, but the higher the degree of customization, the more significant the cost increase. For example, adding specialized insulation and ventilation systems can increase costs by 20%-50%.

Transportation Costs: Transportation distance significantly impacts costs, especially for overseas projects. Buyers should consider transportation method and distance to select an appropriate transportation solution to minimize transportation costs.

Long-Term Costs: While prefabricated warehouses may have slightly higher initial construction costs, their long lifespan, low maintenance costs, and scalability make them highly cost-effective in the long term.

Prefab Warehouse Cost: Affordable Solutions from Shenyang Zhongda

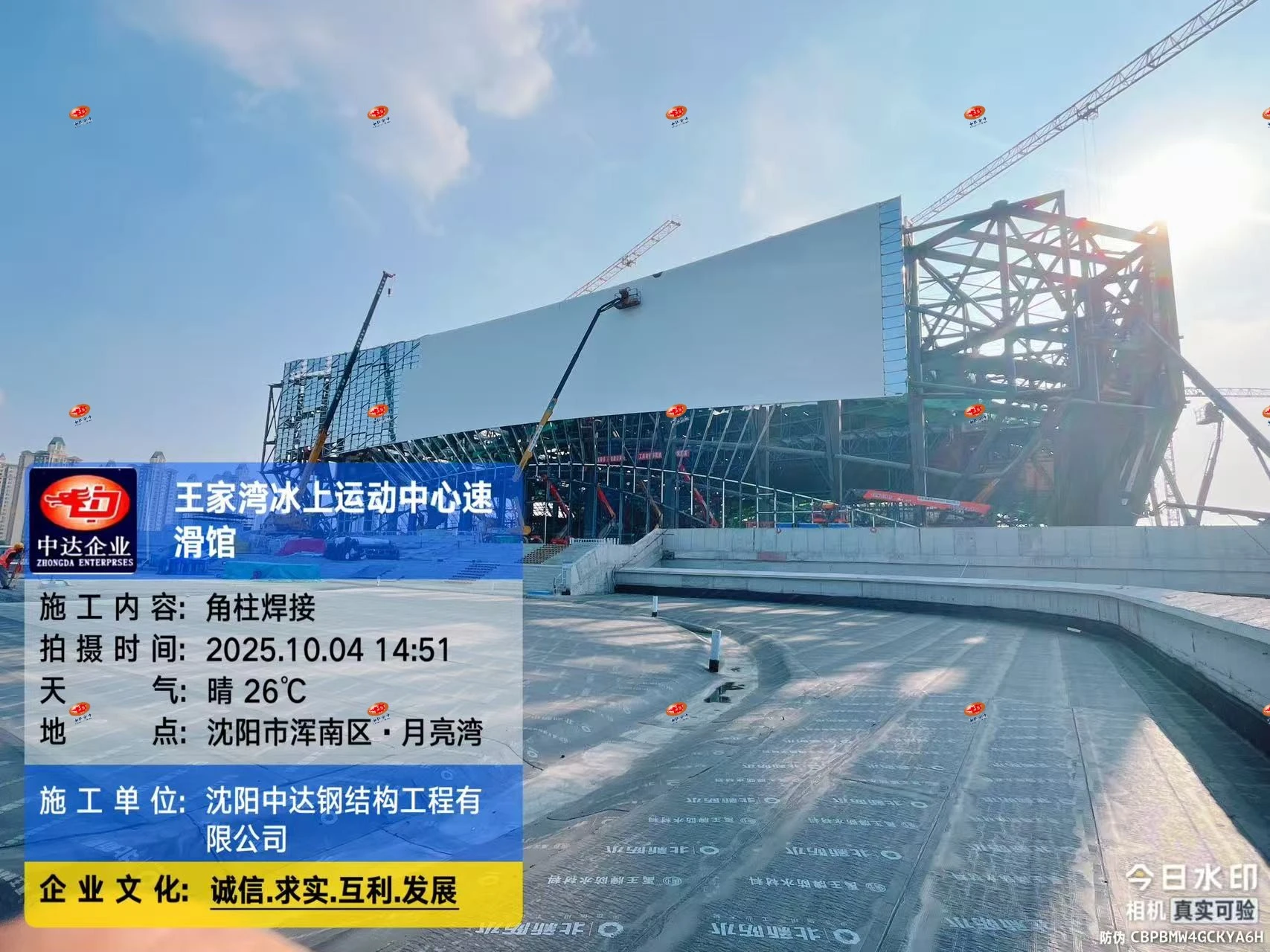

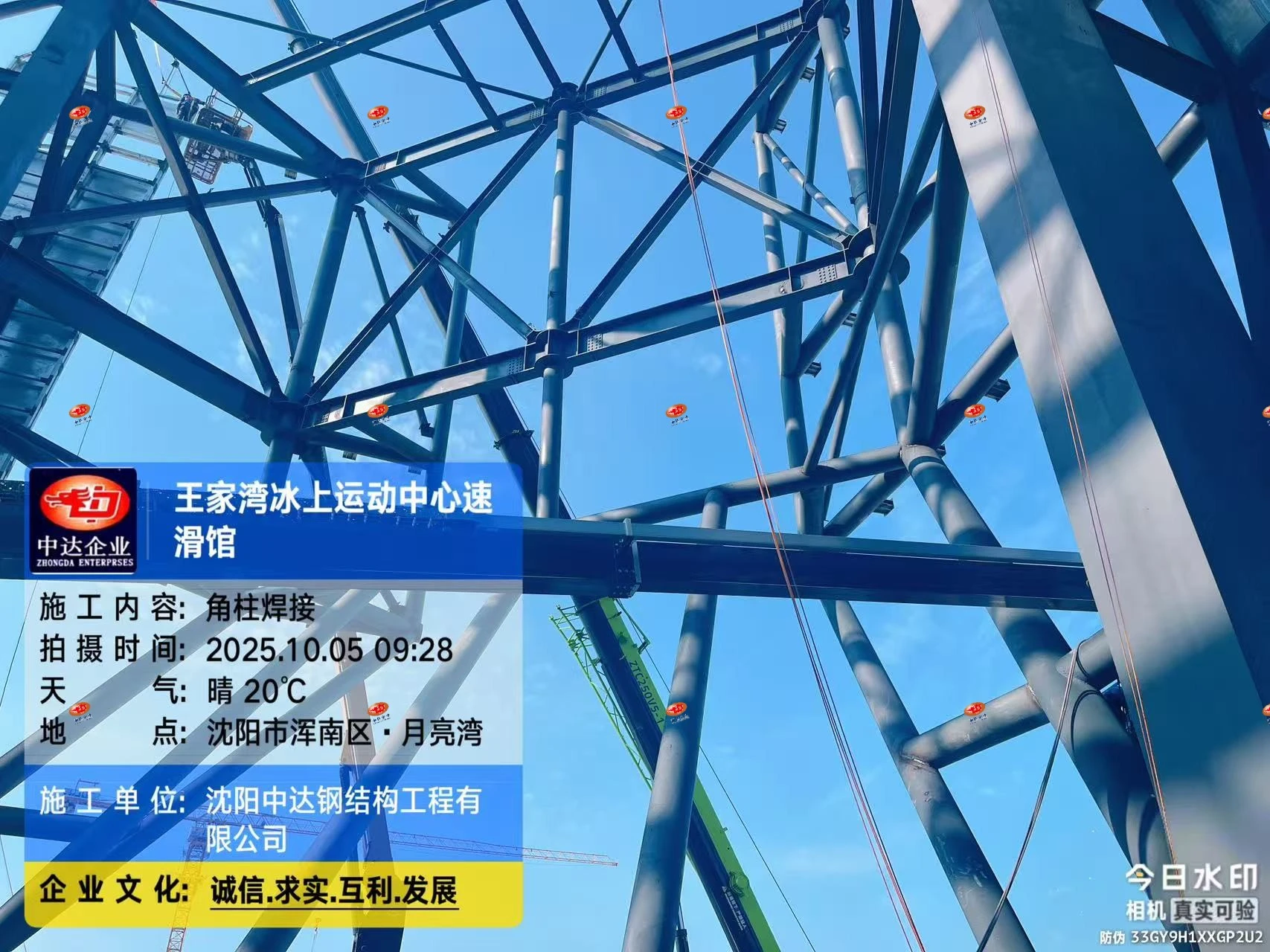

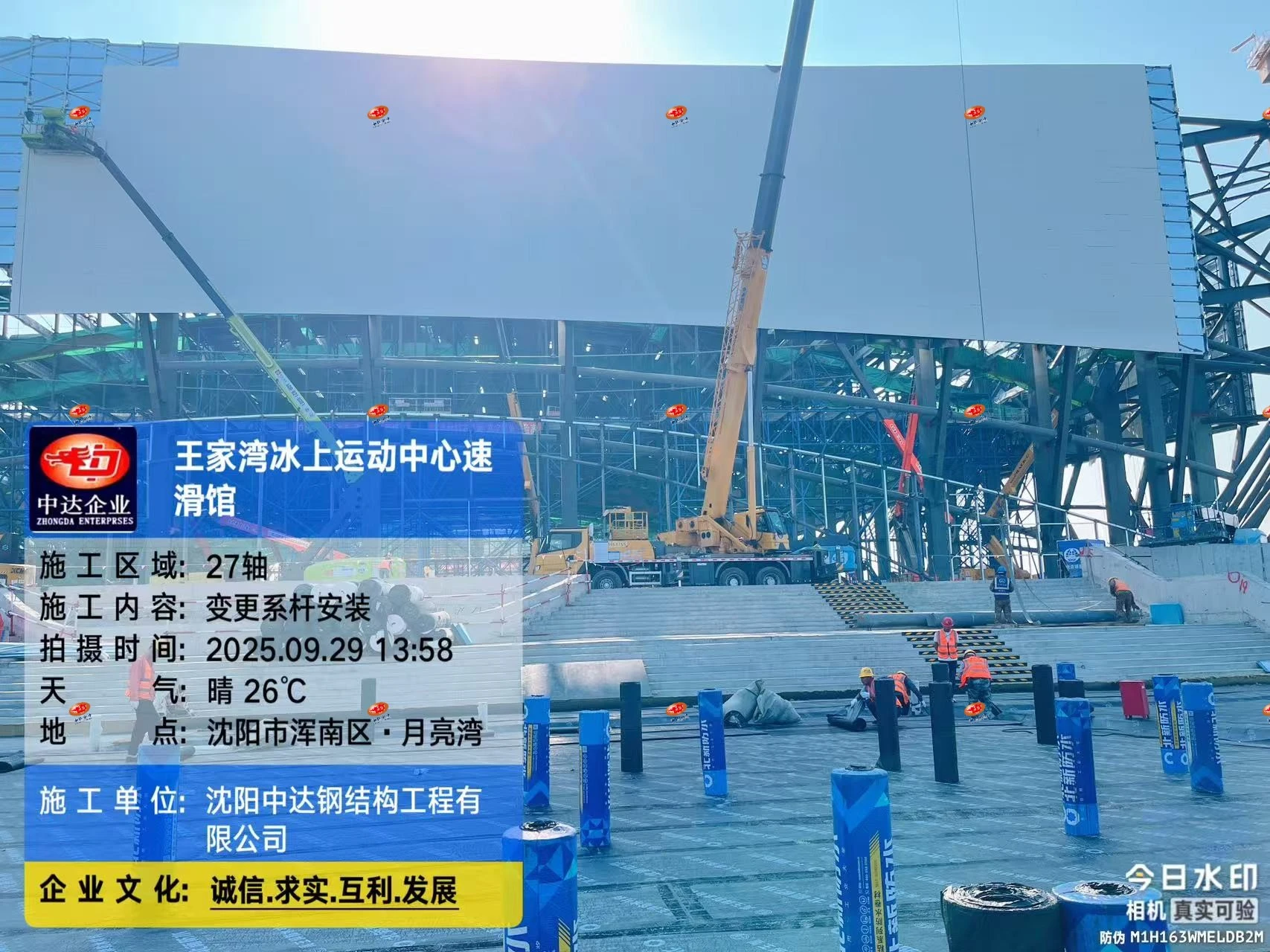

As a leading prefab warehouse cost manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers cost-effective, high-quality solutions for your storage needs. Our advanced production capabilities and experienced team ensure competitive pricing without compromising on durability or customization options. With Zhongda, you'll find the perfect balance of affordability and quality for your prefabricated warehouse project.

Product Description

Our prefabricated warehouses are designed to meet diverse industrial and commercial storage requirements while keeping costs in check. These structures feature:

- Sturdy steel frames for long-lasting stability

- Customizable dimensions to fit your space needs

- Quick assembly, reducing on-site labor expenses

- Energy-efficient insulation options for climate control

- Corrosion-resistant coatings for extended lifespan

- Flexible interior layouts for optimized storage

By choosing Zhongda for your product needs, you'll benefit from our streamlined manufacturing process and bulk material purchasing power. This allows us to offer competitive pricing without sacrificing quality or performance. Our team works closely with clients to develop cost-effective solutions that align with their budget and operational requirements.

Why Choose Us?

Our commitment to quality, efficiency, and customer satisfaction sets us apart:

- 40,000-ton annual steel component production capacity

- In-house design and engineering expertise

- Strict quality control measures

- Global project experience across diverse climates

- Comprehensive after-sales support

Function & Application

Our prefab warehouses are versatile and suitable for various industries:

- Logistics and distribution centers

- Manufacturing facilities

- Agricultural storage

- Retail and e-commerce fulfillment

- Cold storage solutions

These structures can be easily adapted to your specific needs, ensuring optimal functionality while maintaining cost-effectiveness.

Production Process

Our streamlined production process helps minimize prefab warehouse costs:

- Client consultation and design optimization

- Precision cutting and fabrication of steel components

- Quality control inspections at each stage

- Efficient packaging for safe transportation

- On-site assembly support for rapid construction

OEM & ODM Services

We offer customized OEM and ODM services to meet your unique requirements:

- Tailored designs to match your brand aesthetics

- Cost-effective material selection options

- Specialized features integration (e.g., loading docks, ventilation systems)

- Scalable solutions for future expansion

Packaging and Delivery

Our products are carefully packaged to ensure safe transport and easy on-site handling. We offer flexible delivery options to accommodate your project timeline and budget constraints.

Qualification of Company

Shenyang Zhongda holds the First-Class Steel Structure Engineering Qualification from China's Ministry of Housing and Urban-Rural Development. Our ISO 9001-certified quality management system ensures consistent, high-standard product solutions.

FAQs

- Q: How do the products compare to traditional construction?

A: Prefab warehouses typically offer 20-30% cost savings due to reduced labor and faster construction times. - Q: What is the average lead time for a prefab warehouse project?

A: Lead times vary based on size and complexity, but generally range from 4-12 weeks. - Q: Can prefab warehouses be expanded in the future?

A: Yes, our modular designs allow for easy expansion to accommodate your growing needs. - Q: Are there any hidden costs in prefab warehouse construction?

A: We provide transparent pricing, including materials, delivery, and assembly. Site preparation may incur additional costs. - Q: How long do prefab warehouses typically last?

A: With proper maintenance, our prefab warehouses can last 30+ years, offering excellent long-term value.

Contact & Support

Ready to explore cost-effective prefab warehouse cost solutions? Contact our team at postmaster@zd-steels.com for a personalized quote and expert guidance on optimizing your project's budget. We're here to help you achieve the best value for your investment.

YOU MAY LIKE