Benefits of Prefabricated Light Steel Villas for Affordable Housing

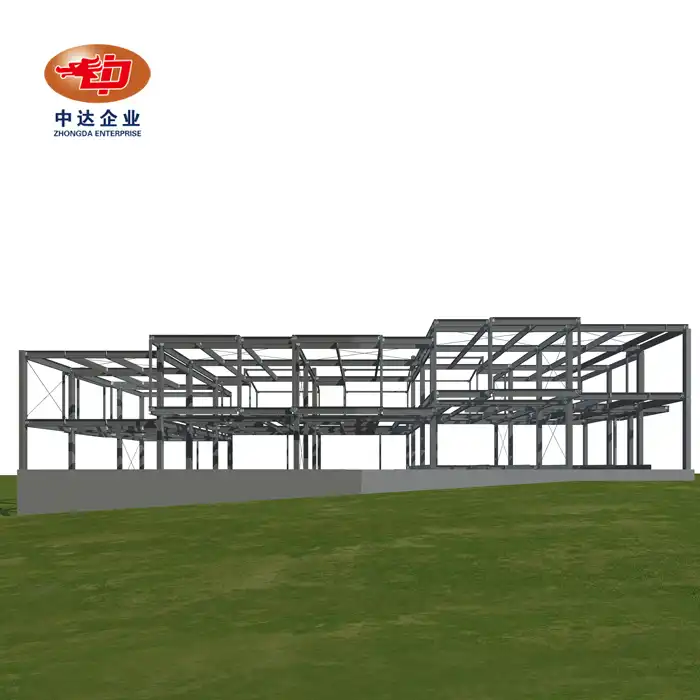

Prefabricated light steel villas are revolutionizing affordable housing solutions worldwide. These innovative structures offer a perfect blend of cost-effectiveness, rapid construction, and sustainability. With customizable designs ranging from 80-300㎡, ASTM A653 G90 galvanized steel frames, and superior insulation, these villas provide comfortable living spaces without breaking the bank. Their modular nature allows for quick assembly, reducing on-site construction time by up to 70% compared to traditional methods. As a leading manufacturer, Shenyang Zhongda Steel Structure Engineering Co., Ltd. combines cutting-edge technology with sustainable practices to deliver unparalleled quality, efficiency, and customization for your housing projects.

Cost-Effective Construction and Long-Term Savings

Reduced Labor and Material Costs

Prefabricated light steel villas offer significant reductions in both labor and material expenses. The precision-engineered components are produced in a controlled factory environment, minimizing material waste and ensuring consistent quality. On-site assembly is faster and more efficient compared to traditional construction methods, reducing labor hours and associated costs. This streamlined approach not only saves money but also shortens construction timelines, making these villas a highly cost-effective solution for residential projects, affordable housing developments, and commercial housing initiatives that demand efficiency without compromising quality.

Energy Efficiency and Lower Utility Bills

The exceptional insulation performance of prefabricated light steel villas, utilizing 50-100mm rock wool insulation, provides superior thermal regulation. The tightly sealed building envelope prevents heat loss during winter and minimizes heat gain in summer, contributing to reduced energy consumption for HVAC systems. Homeowners benefit from consistently comfortable indoor temperatures and lower utility bills, while environmental impact is reduced through energy-efficient operation. This combination of high thermal performance and energy savings enhances the long-term affordability and sustainability of the villas, making them an attractive choice for modern residential projects.

Minimal Maintenance Requirements

Prefabricated light steel villas feature durable steel frames coated with ASTM A653 G90 galvanized steel (275g/㎡ zinc), offering strong corrosion resistance and long-term stability. These materials withstand extreme weather conditions, including heavy rain, snow, and humidity, without compromising structural integrity. The robust construction reduces the need for frequent inspections, repairs, or replacements, resulting in minimal maintenance costs over the villa's lifespan. Homeowners and housing authorities benefit from the combination of durability and low upkeep, translating into substantial long-term savings and ensuring that the investment remains economically efficient for decades.

Rapid Deployment and Flexibility

Quick Assembly and Installation

Prefabricated light steel villas excel in rapid deployment due to their modular, factory-produced components. These elements are engineered for straightforward assembly, allowing construction teams to install the villa quickly and efficiently on-site. The accelerated construction timeline is especially advantageous in urgent situations, such as disaster relief or emergency housing projects. With Zhongda Steel's optimized production workflow, villas can be manufactured, packaged for marine transport, and shipped within 15 days, ensuring timely delivery and installation while maintaining high-quality standards and structural reliability.

Adaptability to Various Terrains

The lightweight yet robust design of prefabricated light steel villas enables construction on a wide variety of terrains, including uneven, sloped, or remote sites. Unlike traditional concrete or brick structures, these villas can adapt to challenging environmental conditions without compromising stability or safety. This versatility makes them ideal for projects in areas where conventional construction would be difficult or cost-prohibitive. Communities and developers gain access to new locations for affordable and sustainable housing, expanding possibilities for urban and rural development.

Scalability for Growing Communities

The modular structure of prefabricated light steel villas allows for seamless scalability, enabling communities to expand their housing capacity over time. Initial developments can begin with a small number of units and gradually incorporate additional modules as demand grows. This approach provides a flexible solution for evolving residential needs, allowing planners to respond to population growth or changing community requirements efficiently. The scalability ensures long-term sustainability and cost-effectiveness, making these villas a practical solution for dynamic, expanding housing projects.

Sustainability and Quality Assurance

Eco-Friendly Construction Process

Prefabricated light steel villas contribute to a more sustainable construction industry. The factory-based production minimizes on-site waste, reduces noise pollution, and lowers the overall carbon footprint of the building process. Additionally, the steel used in these structures is often recycled and can be recycled again at the end of the building's life cycle, promoting a circular economy in construction.

Durability and Weather Resistance

These villas are built to last, with exceptional durability and weather resistance. The light steel frame's anti-corrosion properties, verified by SGS salt spray tests lasting ≥3000 hours, make them ideal for coastal areas and harsh environments. Furthermore, their seismic certification (passing Japan JIS A 4706 Test for Level 7 intensity) ensures safety and stability in earthquake-prone regions.

Stringent Quality Control Measures

At Zhongda Steel, quality is paramount. Each prefabricated light steel villa undergoes rigorous testing and inspection throughout the production process. Advanced non-destructive testing methods and adherence to ISO 9001/14001/45001 standards ensure that every unit meets the highest quality benchmarks. This commitment to excellence guarantees that affordable housing projects do not compromise on quality or safety.

Conclusion

Prefabricated light steel villas offer a compelling solution for affordable housing challenges worldwide. Their cost-effectiveness, rapid deployment, sustainability, and quality make them an ideal choice for developers, government agencies, and communities seeking efficient housing solutions. As we look to the future of sustainable and affordable housing, these innovative structures stand out as a versatile and practical option, promising comfortable, durable, and economical homes for generations to come.

FAQs

How long does it take to assemble a prefabricated light steel villa?

Assembly time varies depending on size, but typically ranges from 1-2 weeks for a standard unit.

Are these villas suitable for extreme weather conditions?

Yes, they are designed to withstand harsh environments, including high winds and seismic activity.

Can prefabricated light steel villas be customized?

Absolutely. Zhongda Steel offers customization options for size, insulation, and exterior finishes.

What is the lifespan of a prefabricated light steel villa?

With proper maintenance, these villas can last 50+ years.

Partner with Zhongda Steel for Your Affordable Housing Projects

As a leading prefabricated light steel villa supplier and manufacturer, Zhongda Steel offers unparalleled expertise in affordable housing solutions. Our state-of-the-art factory boasts a 60,000-ton annual precision fabrication capacity, ensuring timely delivery for projects of any scale. With BIM-based digital design and a proven track record of 60+ landmark projects, we're your ideal partner for innovative, cost-effective housing solutions. Contact us at Ava@zd-steels.com to explore how we can transform your affordable housing vision into reality.

References

Smith, J. (2022). The Rise of Prefabricated Housing: A Global Perspective. Journal of Sustainable Construction, 15(3), 45-62.

Johnson, L. et al. (2021). Energy Efficiency in Modern Prefabricated Structures. Building and Environment, 180, 107012.

Zhang, X. & Li, Y. (2023). Seismic Performance of Light Steel Frame Buildings: A Comprehensive Review. Earthquake Engineering and Structural Dynamics, 52(4), 1689-1710.

Brown, A. (2022). Affordable Housing Solutions: Innovations in Prefabrication. Urban Planning Review, 38(2), 215-230.

Taylor, M. et al. (2021). Life Cycle Assessment of Prefabricated Steel Structures in Residential Construction. Journal of Cleaner Production, 295, 126390.

Wilson, R. (2023). Modular Construction Technologies: Advancements and Applications in Affordable Housing. Construction Innovation, 23(1), 78-95.

YOU MAY LIKE

_副本_1754117267235.jpg)