Challenges of Operating Mobile Crushing Stations in Extreme Cold

Material Brittleness and Structural Integrity

When temperatures plummet to -50°C, standard steel becomes brittle and prone to fracture. This poses significant risks for mobile crushing stations, as the immense forces involved in crushing rock can cause catastrophic failures if materials aren't properly selected. Our engineers at Zhongda Steel have tackled this challenge head-on by utilizing S355J2W and other high-nickel alloy steels specifically formulated to maintain toughness at ultra-low temperatures. These specialized steels exhibit impact strength of ≥27J at -60°C, ensuring our mobile crushers maintain structural integrity even in the most extreme Arctic conditions.

Lubrication and Hydraulic System Issues

Extreme cold dramatically increases the viscosity of lubricants and hydraulic fluids, potentially leading to equipment seizure or failure. To combat this, we've implemented multi-grade synthetic lubricants and hydraulic oils specifically engineered for Arctic use. These specialized fluids maintain proper viscosity across a wide temperature range, ensuring smooth operation of all moving parts and hydraulic systems. Additionally, we've redesigned hydraulic circuits to minimize pressure drops and incorporated trace heating elements in critical components to prevent fluid thickening during idle periods.

Engine Starting and Fuel System Complications

Diesel engines face significant starting difficulties in extreme cold, as fuel can gel and batteries lose capacity. Our mobile crushing stations overcome these hurdles through a multi-faceted approach. We equip our units with cold-weather adapted diesel engines, such as those from the Weichai series, known for their reliable cold-start capabilities. Integrated fuel heating systems prevent diesel gelling, while high-capacity cold-cranking batteries and engine block heaters ensure dependable starts even at -50°C. By addressing these critical areas, we've created mobile crushing stations that fire up reliably in even the most frigid environments.

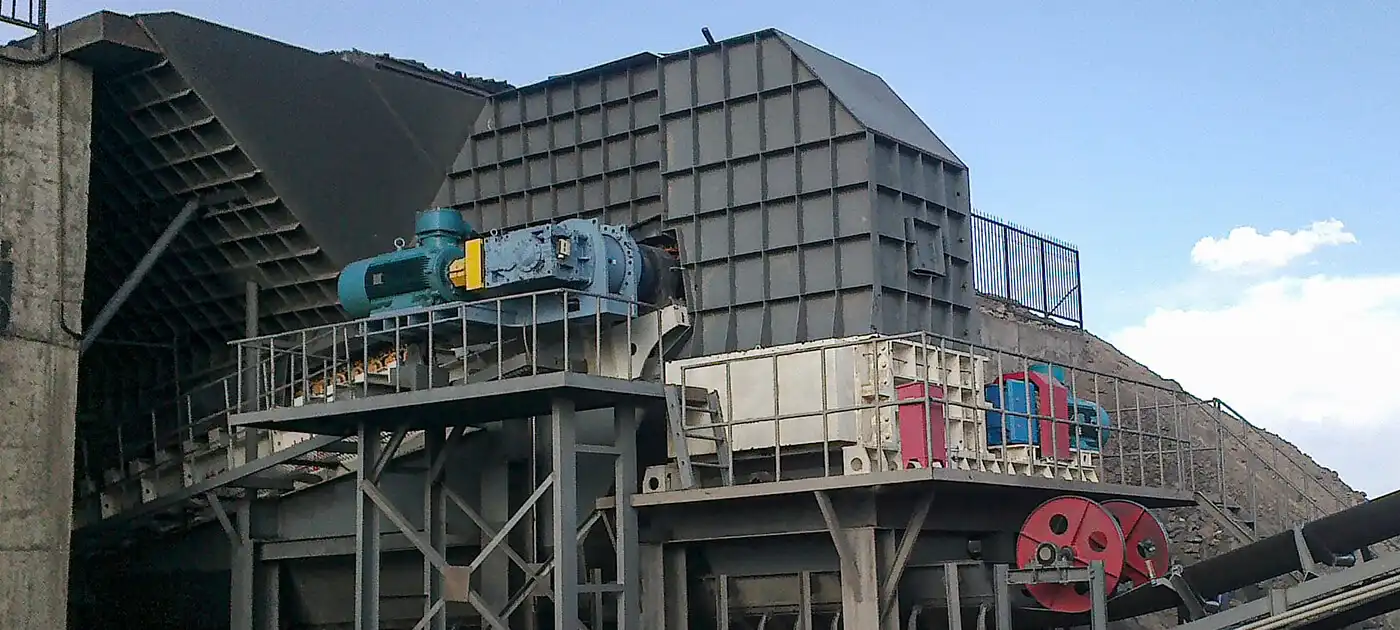

Innovative Design Features for Arctic-Grade Mobile Crushers

Advanced Materials and Fabrication Techniques

At Zhongda Steel, we've pushed the boundaries of materials science to create mobile crushers that thrive in extreme cold. Our use of S355J2W and similar high-toughness alloy steels isn't limited to just the main structure. We've extended this approach to critical wear components, crusher jaws, and even fasteners, ensuring every element of the machine maintains its strength and resilience at -50°C. Our fabrication process employs specialized low-hydrogen welding techniques, carefully controlled pre-heating, and post-weld heat treatments to eliminate the risk of cold cracking in welded joints. This comprehensive approach to materials and fabrication results in a mobile crushing station that maintains its structural integrity and crushing performance in the most demanding Arctic environments.

Thermal Management and Insulation Systems

Effective thermal management is crucial for reliable operation in extreme cold. Our Arctic-grade crawler-type mobile crushing stations incorporate multi-layered insulation systems to protect critical components and maintain optimal operating temperatures. High-efficiency heat exchangers recover waste heat from the engine and hydraulic systems, redirecting it to warm vital areas of the machine. We've also implemented smart thermal monitoring systems that continuously adjust heat distribution based on real-time temperature data, ensuring all systems remain within their ideal operating range. This proactive approach to thermal management significantly reduces warm-up times and prevents cold-related failures, maximizing uptime in harsh winter conditions.

Cold-Adapted Control Systems and Electronics

Modern mobile crushing stations rely heavily on sophisticated electronic control systems, which can be particularly vulnerable to extreme cold. Our engineering team has developed ruggedized control panels and sealed electronic enclosures capable of withstanding -50°C temperatures. We utilize military-grade components rated for Arctic use, including low-temperature LCD displays that remain responsive in severe cold. To further enhance reliability, we've implemented redundant systems for critical controls and incorporated self-diagnostic capabilities that can identify and mitigate potential cold-weather issues before they lead to equipment failure. These advanced control systems ensure precise, responsive operation of the mobile crusher, even in the most challenging Arctic environments.

Maintenance and Operational Considerations for Extreme Cold Environments

Specialized Cold Weather Maintenance Procedures

Operating mobile crushing stations in extreme cold environments requires a tailored approach to maintenance. At Zhongda Steel, we provide comprehensive cold weather maintenance guidelines with each Arctic-grade mobile crusher. These procedures include detailed instructions for proper warm-up and cool-down cycles, which are critical for preventing thermal shock to components. We recommend more frequent inspections of seals, hoses, and other elastomeric components, as extreme cold can accelerate degradation of these materials. Our maintenance protocols also emphasize the importance of moisture control, as any water ingress can lead to rapid freezing and equipment damage. By following these specialized procedures, operators can significantly extend the lifespan of their mobile crushing stations and minimize downtime in harsh Arctic conditions.

Operator Training for Arctic Conditions

The unique challenges of operating mobile crushing stations in extreme cold demand specialized operator training. Zhongda Steel offers comprehensive Arctic operations courses for crews working with our cold-weather adapted equipment. These training programs cover essential topics such as proper cold-start procedures, recognizing signs of cold-related equipment stress, and optimizing crusher settings for frozen or partially frozen material. We also emphasize the importance of personal safety in extreme cold environments, including proper use of Arctic-grade PPE and recognition of cold-weather health hazards. By equipping operators with this specialized knowledge, we ensure that our mobile crushing stations are used safely and efficiently, even in the most demanding cold-weather applications.

Logistical and Supply Chain Considerations

Successful operation of mobile crushing stations in remote Arctic locations requires careful logistical planning. Zhongda Steel works closely with our clients to develop comprehensive supply chain strategies for spare parts, consumables, and specialized Arctic-grade fluids. We recommend maintaining larger on-site inventories of critical components to account for potential shipping delays due to severe weather. Our parts department offers customized kitting solutions, pre-assembling collections of cold-weather specific maintenance items to streamline on-site repairs. Additionally, we provide guidance on proper storage of spare parts and fluids in extreme cold conditions, ensuring that these vital supplies remain ready for use when needed. By addressing these logistical challenges proactively, we help our clients maintain high levels of equipment availability in even the most isolated Arctic crushing operations.

Conclusion

Mobile crushing stations can indeed operate reliably in extreme cold conditions reaching -50°C, provided they are specifically engineered for Arctic use. Through innovative material selection, advanced thermal management, and specialized maintenance practices, these rugged machines can maintain productivity in the harshest winter environments. As the demand for resource extraction in cold regions continues to grow, Arctic-adapted mobile crushers will play an increasingly vital role in efficient, year-round operations.

Contact Us

At Zhongda Steel, we're at the forefront of developing mobile crushing solutions that thrive in extreme cold. Our Arctic-grade crushers combine innovative engineering with uncompromising quality, ensuring reliable performance in the world's most challenging environments. To learn more about how our cold-weather adapted mobile crushing stations can benefit your operations, contact us at Ava@zd-steels.com. Let Zhongda Steel's expertise in Arctic engineering power your success in extreme conditions.