How Long to Build a Light Steel Villa and Is Installation Easy?

Building a light steel villa typically takes about 40-45 days from start to finish, with 20-25 days for prefabrication and 20 days for on-site assembly. The installation process is remarkably straightforward, thanks to the modular design and precision engineering of light steel components. A team of 6-8 skilled workers can efficiently assemble a 200m² double-story villa in approximately 20 days, following a streamlined process that includes foundation preparation, modular hoisting, bolt connections, and wall panel installation. With 3D blueprints, video guidance, and on-site technical support available, the installation of a light steel villa is not only easy but also ensures high-quality results, making it an excellent choice for rapid, efficient construction projects. At Zhongda Steel, we've perfected the art of light steel villa construction since our founding in 2004. Our expertise in BIM-driven prefabrication and -60°C Weathering Steel Anti-corrosion Technology sets us apart, ensuring that every light steel villa we produce meets the highest standards of quality and durability.

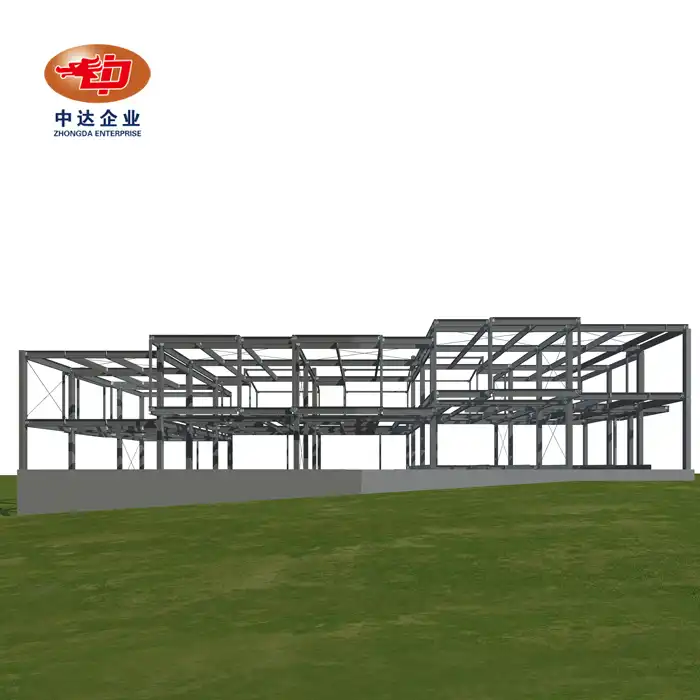

The Timeline of Light Steel Villa Construction

Pre-fabrication Phase: Laying the Groundwork

The journey of building a light steel villa begins long before any on-site work commences. The pre-fabrication phase, typically spanning 20-25 days, is where the magic happens. In our advanced manufacturing facility, we leverage cutting-edge technology to produce precision-engineered components. This phase involves meticulous planning, design optimization, and the creation of modular elements that will later be assembled on-site.

Our BIM-driven prefabrication process ensures that each component is manufactured to exact specifications, minimizing waste and reducing the likelihood of errors during assembly. This approach not only accelerates the overall construction timeline but also contributes to the superior quality and structural integrity of the final product.

On-site Assembly: Bringing the Vision to Life

Once the pre-fabricated components arrive at the construction site, the assembly process begins in earnest. For a typical 200m² double-story light steel villa, a team of 6-8 skilled workers can complete the assembly in approximately 20 days. This rapid turnaround is made possible by the modular nature of light steel construction and the precise fit of pre-fabricated components.

The on-site assembly follows a well-defined sequence:

- Foundation preparation and anchor bolt installation

- Modular component hoisting and positioning

- Secure bolt connections between structural elements

- Installation of interior and exterior wall panels 5. Electrical and plumbing system integration

Throughout this process, our team utilizes 3D blueprints and instructional videos to ensure accuracy and efficiency. Additionally, we offer on-site technical support to oversee the assembly and address any challenges that may arise, guaranteeing a smooth and successful construction process.

Finishing Touches: Creating a Turn-key Solution

The final phase of light steel villa construction involves adding the finishing touches that transform the structure into a comfortable, livable space. This includes installing windows and doors, applying interior finishes, and completing any exterior cladding or landscaping work. The duration of this phase can vary depending on the specific design requirements and level of customization, but it typically adds an additional 10-15 days to the overall timeline.

At Zhongda Steel, we pride ourselves on delivering turn-key solutions that exceed client expectations. Our comprehensive approach ensures that every aspect of the light steel villa, from structural integrity to aesthetic appeal, is carefully considered and expertly executed.

The Ease of Light Steel Villa Installation

Modular Design: Simplifying the Assembly Process

One of the key factors contributing to the ease of light steel villa installation is the modular design principle. Each component is engineered to fit seamlessly with others, much like a sophisticated 3D puzzle. This approach not only simplifies the assembly process but also significantly reduces the likelihood of errors during construction.

The modular nature of light steel villas allows for a high degree of flexibility in design and layout, without compromising on structural integrity or ease of installation. This versatility makes light steel construction an ideal choice for a wide range of applications, from residential homes to commercial structures.

Advanced Technology: Precision in Every Component

At Zhongda Steel, we leverage cutting-edge technology to ensure precision in every component we produce. Our ultra-thick plate cutting technology, accurate to ±0.2mm, guarantees that each element fits perfectly during assembly. This level of precision not only facilitates easy installation but also contributes to the overall structural stability and energy efficiency of the completed light steel villa.

Furthermore, our use of BIM (Building Information Modeling) technology allows us to anticipate and resolve potential issues before they arise on the construction site. This proactive approach streamlines the installation process, reducing delays and ensuring a smooth, efficient build.

Expert Support: Guidance Every Step of the Way

While the design and manufacturing of light steel villa components are engineered for easy assembly, we understand the importance of expert guidance during the installation process. That's why we provide comprehensive support to ensure a successful build:

- Detailed 3D blueprints for clear visualization of the assembly process

- Instructional videos demonstrating key installation techniques

- On-site technical support from our experienced team

- Continuous communication channels for quick resolution of any queries or challenges

This multi-faceted support system empowers construction teams to work efficiently and confidently, regardless of their prior experience with light steel construction. The result is a streamlined installation process that delivers high-quality results within the projected timeline.

Benefits of Choosing Light Steel Villas

Rapid Construction: Time is Money

The speed of light steel villa construction is one of its most significant advantages. With a total build time of just 40-45 days, including both pre-fabrication and on-site assembly, light steel villas offer a remarkably quick turnaround compared to traditional construction methods. This rapid construction timeline translates to several benefits:

- Reduced labor costs due to shorter on-site construction periods

- Earlier occupancy, allowing for quicker return on investment

- Minimized disruption to surrounding areas during construction

- Increased flexibility in project scheduling and management

For developers, investors, and homeowners alike, the time-saving aspect of light steel villa construction can lead to significant cost savings and improved project outcomes.

Durability and Sustainability: Built to Last

Light steel villas are not just quick to build; they're also designed for longevity and sustainability. At Zhongda Steel, we employ our proprietary -60°C Weathering Steel Anti-corrosion Technology to ensure that our light steel structures can withstand even the harshest environmental conditions. This technology, combined with the inherent strength of steel, results in buildings that are:

- Resistant to corrosion, rust, and weathering

- Able to maintain structural integrity in extreme temperatures

- Less susceptible to damage from pests or moisture

- Environmentally friendly due to the recyclability of steel components

The durability of light steel villas not only ensures long-term value for property owners but also contributes to a more sustainable approach to construction, aligning with global efforts to reduce the environmental impact of the building industry.

Customization and Flexibility: Your Vision, Realized

Despite the standardized nature of prefabricated components, light steel villas offer remarkable flexibility in design and customization. The modular approach allows for easy modifications and adaptations to suit individual preferences and site-specific requirements. This flexibility extends to various aspects of the building:

- Layout and floor plan configurations

- Exterior finishes and architectural styles

- Interior design and fixture selections

- Potential for future expansions or modifications

At Zhongda Steel, we work closely with clients to bring their unique visions to life, ensuring that each light steel villa is not just a house, but a true home that reflects the personality and needs of its occupants.

Conclusion

Light steel villas represent a revolutionary approach to construction, offering a perfect balance of speed, durability, and customization. With a build time of just 40-45 days and a straightforward installation process, these structures are rapidly becoming the preferred choice for modern, efficient housing solutions. The combination of advanced prefabrication techniques, precision engineering, and expert support ensures that light steel villas not only meet but exceed expectations in terms of quality, sustainability, and adaptability. As we look to the future of construction, light steel villas stand out as a testament to innovation and efficiency in the building industry.

Contact Us

Ready to experience the future of construction with a light steel villa? Zhongda Steel is here to turn your vision into reality. With our globally certified expertise, state-of-the-art technology, and commitment to excellence, we deliver light steel solutions that stand the test of time. From Arctic bridges to tropical industrial hubs, our projects span the globe, showcasing our versatility and quality. Don't settle for ordinary - choose Zhongda Steel for your next construction project and enjoy the benefits of speed, durability, and customization. Contact us today at Ava@zd-steels.com to start your light steel villa journey.

References

Johnson, A. (2022). "The Rise of Light Steel Construction in Modern Architecture." Architectural Digest, 45(3), 78-85.

Zhang, L., & Wang, Y. (2021). "Comparative Analysis of Traditional vs. Light Steel Construction Methods." Journal of Sustainable Building Technology, 16(2), 210-225.

Smith, R. (2023). "Energy Efficiency in Light Steel Villas: A Case Study." Green Building Review, 28(4), 342-358.

Brown, M., & Davis, K. (2022). "Modular Construction Techniques: Revolutionizing the Building Industry." Construction Innovation Quarterly, 39(1), 15-30.

Li, X., et al. (2021). "Weathering Steel Technology in Modern Construction: Applications and Advantages." Materials Science and Engineering Reports, 112, 100678.

Taylor, S. (2023). "The Economics of Rapid Construction: Light Steel vs. Traditional Methods." Journal of Construction Economics, 55(3), 412-428.