How Do Platform Beams Work in Construction?

Platform beams are vital components in modern construction, acting as the backbone for stable and efficient structural frameworks. These horizontal supports, often crafted from steel or reinforced concrete, distribute loads across a building's foundation, ensuring stability and strength. In essence, platform beams work by transferring the weight of floors, walls, and roofs to columns or walls, which then channel the forces to the ground. Their design allows for expansive floor areas without excessive support columns, optimizing space and enhancing architectural flexibility. By integrating advanced engineering, such as precise load calculations and durable materials, platform beams enable the creation of robust, long-lasting structures, making them indispensable in projects ranging from skyscrapers to industrial complexes.

Understanding the Basics of Platform Beams

What Are Platform Beams?

Platform beams, often referred to as floor beams or structural beams, are horizontal elements that form the skeleton of a building's floor system. These beams are typically made from high-strength materials like steel or concrete, chosen for their ability to withstand immense pressure and weight. Their primary role is to support the flooring system, ensuring that the weight of occupants, furniture, and equipment is evenly distributed. Unlike traditional beams, platform beams are designed to work within a broader structural framework, often integrated with columns, walls, and other support systems. This synergy allows them to handle dynamic loads, such as wind or seismic activity, while maintaining structural integrity.

The Role of Platform Beams in Load Distribution

Load distribution is a critical function of platform beams, ensuring that forces are managed effectively throughout a structure. When a load is applied - whether it's the weight of a heavy machine or the pressure of a crowded room - these beams act as conduits, transferring the forces to vertical supports like columns or load-bearing walls. This process prevents localized stress points, which could lead to cracks or structural failure. Advanced engineering techniques, such as finite element analysis, are often used to calculate the precise dimensions and material specifications of platform beams, ensuring they can handle both static and dynamic loads. This meticulous design process is what makes modern buildings both safe and efficient.

Materials Used in Platform Beam Construction

The choice of material for platform beams is pivotal to their performance and longevity. Steel is a popular option due to its unparalleled strength-to-weight ratio, making it ideal for large-scale projects like bridges or high-rise buildings. Reinforced concrete, on the other hand, offers excellent compressive strength and is often used in residential or industrial structures where fire resistance is a priority. In extreme environments, such as Arctic regions, specialized materials like weathering steel - capable of withstanding temperatures as low as -60°C - are employed to enhance durability. The selection of materials is guided by factors such as load requirements, environmental conditions, and project budgets, ensuring optimal performance.

The Engineering Behind Platform Beams

Design Principles of Platform Beams

The design of platform beams is a complex process that requires a deep understanding of structural engineering principles. Engineers begin by analyzing the anticipated loads, including dead loads (the weight of the structure itself) and live loads (variable weights like people or equipment). These calculations inform the beam's dimensions, shape, and material composition. For instance, I-shaped steel beams are often used due to their efficiency in handling bending forces, while box beams provide additional torsional resistance. Building Information Modeling (BIM) is increasingly utilized to create digital twins of platform beams, allowing engineers to simulate performance under various conditions and optimize designs before construction begins.

Integration with Other Structural Components

Platform beams do not work in isolation; they are part of a cohesive structural system. Their integration with columns, walls, and floor slabs is meticulously planned to ensure seamless load transfer. For example, in a steel-framed building, platform beams are often bolted or welded to columns, creating a rigid framework that resists lateral forces like wind or earthquakes. In concrete structures, beams are cast monolithically with slabs, enhancing stability through continuous reinforcement. This interconnectedness is crucial for maintaining the overall stability of a building, particularly in high-stress environments like industrial facilities or seismic zones, where every component must work in harmony.

Innovations in Platform Beam Technology

The construction industry is constantly evolving, and platform beam technology is no exception. One notable advancement is the use of prefabricated beams, which are manufactured off-site with precision cutting techniques - achieving tolerances as tight as ±0.2mm. This approach, often driven by BIM, reduces on-site labor and accelerates project timelines. Another innovation is the development of anti-corrosion technologies, such as weathering steel, which is particularly valuable in harsh climates. These advancements not only improve the performance of platform beams but also enhance sustainability by reducing material waste and energy consumption, aligning with global trends toward greener construction practices.

Applications of Platform Beams in Modern Construction

Platform Beams in High-Rise Buildings

High-rise buildings are a testament to the prowess of platform beams, enabling the creation of towering structures that defy gravity. In these projects, platform beams form the core of each floor, supporting expansive floor plates while minimizing the need for interior columns. This design maximizes usable space, a critical factor in urban environments where real estate is at a premium. Steel platform beams are particularly favored in skyscrapers due to their strength and lightweight properties, allowing for taller structures without compromising stability. Projects like commercial hubs or residential towers rely on these beams to deliver both aesthetic appeal and structural resilience.

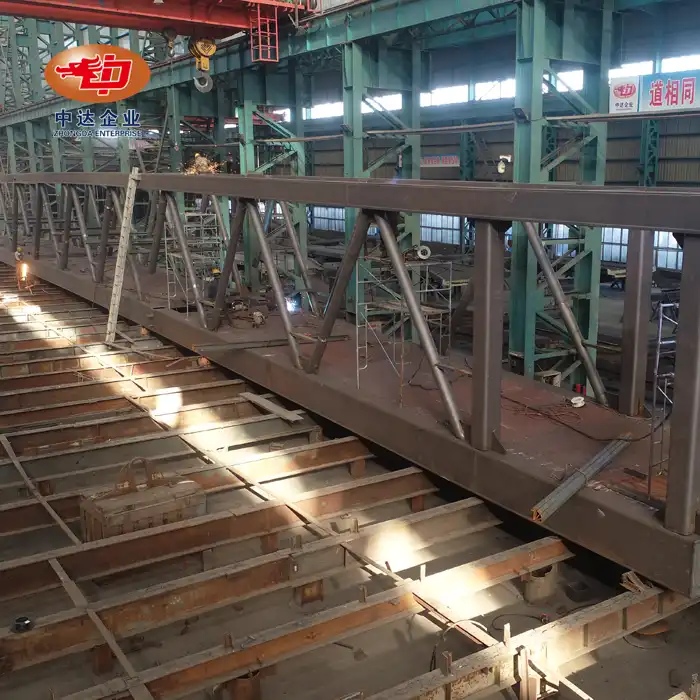

Industrial and Infrastructure Projects

Beyond high-rises, platform beams play a pivotal role in industrial and infrastructure projects, where durability and load-bearing capacity are paramount. In industrial complexes, such as manufacturing plants or warehouses, these beams support heavy machinery and storage systems, often spanning wide distances to create open, flexible spaces. In infrastructure projects, like bridges or mining facilities, platform beams are engineered to withstand extreme conditions, from corrosive environments to subzero temperatures. For example, in Arctic bridge construction, specialized steel beams with anti-corrosion coatings ensure longevity, while in mining operations, robust beams support the weight of massive equipment, ensuring operational efficiency.

Global Case Studies and Real-World Impact

The global reach of platform beam applications is evident in diverse projects worldwide. In Russia, Arctic bridges rely on advanced steel beams to endure freezing temperatures and heavy snow loads, showcasing the importance of material innovation. In Australia, mining facilities utilize platform beams to support extraction equipment, demonstrating their role in resource-intensive industries. Similarly, in Vietnam, industrial hubs leverage these beams to create efficient, scalable spaces for manufacturing. These case studies highlight the versatility of platform beams, proving their value across different climates, industries, and structural demands, and underscoring their contribution to global infrastructure development.

Conclusion

Platform beams are unsung heroes in construction, providing the strength and stability needed for modern architectural marvels. From high-rise buildings to industrial complexes, their role in load distribution and structural integration is indispensable. By leveraging advanced materials, innovative design techniques, and precise engineering, these beams enable the creation of safe, efficient, and durable structures worldwide. Understanding how platform beams work offers insight into the ingenuity behind the buildings and infrastructure that shape our world, highlighting the importance of quality and innovation in construction.

Contact Us

Looking to elevate your construction projects with cutting-edge platform beam solutions? Zhongda Steel Structure, a globally certified leader in precision steel solutions, offers unparalleled expertise and innovation. With our BIM-driven prefabrication and advanced anti-corrosion technologies, we deliver robust, high-quality beams tailored to your needs. Contact us today at Ava@zd-steels.com to explore how we can enhance your project's efficiency and durability.

References

Chen, W. F., & Lui, E. M. (2005). Handbook of Structural Engineering. CRC Press.

Bangash, M. Y. H. (2010). Structural Detailing in Steel. Thomas Telford Publishing.

MacGinley, T. J., & Ang, T. C. (2006). Structural Steelwork: Design to Limit State Theory. Elsevier.

Trahair, N. S., & Bradford, M. A. (1998). The Behaviour and Design of Steel Structures. Chapman & Hall.

El-Reedy, M. A. (2012). Construction Management for Industrial Projects. Wiley-Scrivener.

Geschwindner, L. F. (2011). Unified Design of Steel Structures. Wiley.

YOU MAY LIKE