2. Certification: CE (EN 1090 - 2), ISO 3834, 3rd - party test reports.

3. Custom: Track/wheel base, 800×1200 - 1500×2000mm feed, adj. output.

4. Delivery: 30 days std, 45 days non - std (incl. ocean freight).

5. Application: Mine/cwaste crushing, 200 - 800t/hour capacity.

6. Tech: Hydraulic folding conveyor, 60% time reduction.

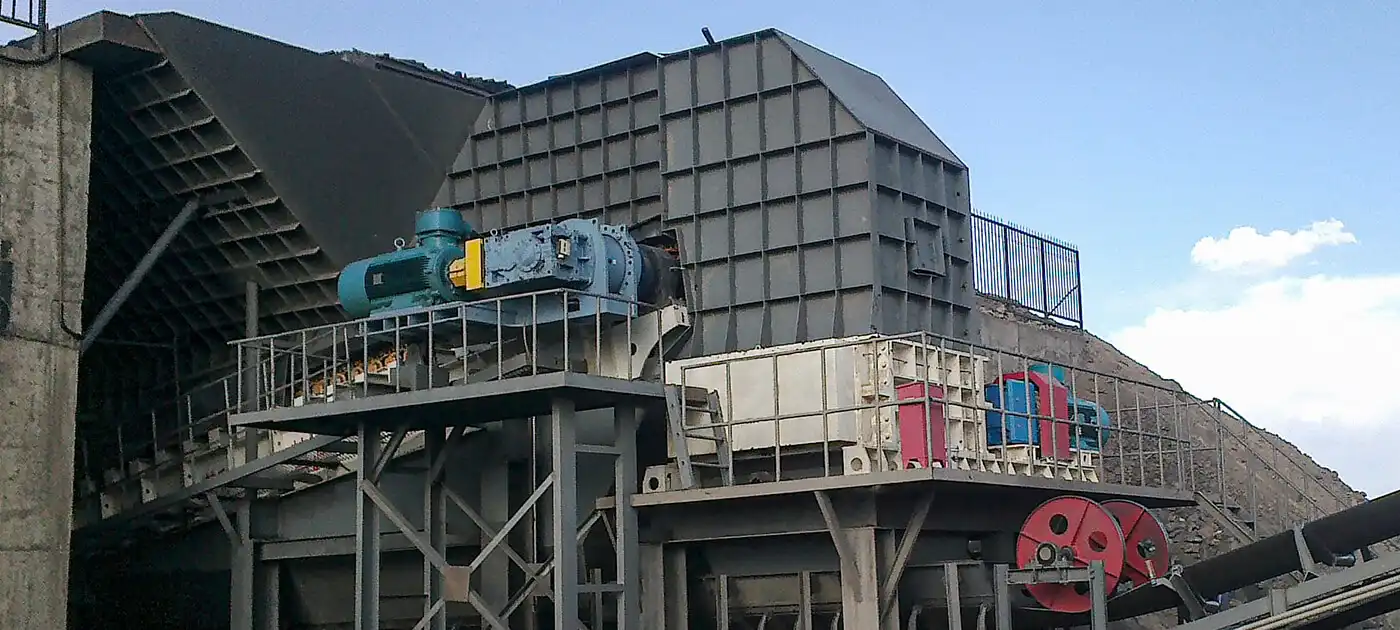

Mining Crushing Stations: Powering Efficient Mineral Processing

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of high-performance mining crushing stations. Our advanced crushing solutions offer superior efficiency, durability, and customization options, making us the preferred choice for mining operations worldwide. With our state-of-the-art manufacturing capabilities and innovative design expertise, we deliver crushing stations that maximize productivity and minimize downtime.

Product Description:

Our products are engineered to meet the demanding requirements of modern mining operations. Featuring robust construction with Q345B high-strength steel and NM400 wear-resistant steel plates, these stations are built to withstand the harshest operating conditions. The modular design allows for seamless integration with jaw crushers and cone crushers, offering flexibility in processing various materials. With customizable feed openings ranging from 800×1200mm to 1500×2000mm and adjustable discharge systems, our crushing stations can be tailored to your specific production needs, handling 200-800 tons per hour with ease.

Product Features:

- Hydraulic folding conveyor frame design reduces relocation and installation time by 60%

- Track-based or wheel-based mobility options for enhanced site versatility

- Advanced wear-resistant materials ensure extended service life

- Modular construction facilitates easy maintenance and upgrades

Quality Control:

We maintain rigorous quality standards throughout the production process. Our mining crushing stations are CE certified (EN 1090-2) and manufactured under ISO 3834 welding system guidelines. Each unit undergoes comprehensive third-party nondestructive testing, ensuring the highest level of reliability and performance. Our commitment to quality extends from material selection to final assembly, guaranteeing you receive a product that exceeds industry standards.

Why Choose Us?

As a National High-Tech Enterprise with a Class I Steel Structure Professional Contracting Qualification, we offer unparalleled expertise in mining equipment manufacturing. Our vertically integrated capabilities, from R&D to precision fabrication and on-site installation, ensure seamless project execution. With a proven track record of delivering over 60 landmark projects and a 70% client retention rate, we're your trusted partner for the products that drive operational excellence.

Production Process:

Our production process is a model of efficiency and precision. By leveraging state - of - the - art CNC equipment, we can achieve micron - level accuracy in machining operations. Automated welding lines further enhance our capabilities, delivering consistent, high - quality welds across all components. This streamlined approach not only ensures that each part meets the strictest quality standards but also significantly reduces production time. With every component passing through our advanced manufacturing system, clients can rely on products that are both precise and uniformly excellent in quality.

OEM & ODM Services:

We offer comprehensive OEM and ODM services to meet your unique requirements. Our experienced engineering team collaborates closely with clients to develop custom crushing station solutions that align with specific operational needs. Whether you require specialized material specifications, unique mobility features, or integration with existing equipment, we have the expertise to deliver. Our flexible manufacturing capabilities allow us to accommodate various production volumes, from small batches to large-scale orders, all while maintaining our commitment to quality and timely delivery.

Project Cases:

Our products have been successfully deployed in diverse mining operations globally. Notable projects include:

- A large-scale copper mine in Chile, where our custom-designed crushing station increased throughput by 25% while reducing energy consumption.

- An iron ore processing facility in Australia, featuring our track-mounted crushing station that improved site mobility and reduced setup time by 40%.

- A construction waste recycling operation in the Middle East, utilizing our adaptable crushing station to process various materials efficiently.

These case studies demonstrate our ability to deliver tailored solutions that address unique challenges and drive tangible improvements in mining operations.

Certifications:

CE Certified (EN 1090-2), ISO 9001:2015, ISO 14001:2015, ISO 45001:2018

Packaging and Delivery:

We provide secure packaging optimized for ocean freight, ensuring safe transportation. Standard models are delivered within 30 days, while custom designs typically require 45 days.

FAQ:

Q: What is the typical ROI for your products?

A: While ROI varies based on specific applications, our clients typically see a return within 12-18 months due to increased productivity and reduced maintenance costs.

Q: How do you ensure after-sales support for global customers?

A: We offer comprehensive after-sales service, including remote diagnostics, on-site technical support, and a global spare parts network to minimize downtime.

Q: Can your crushing stations be integrated with our existing equipment?

A: Absolutely. Our modular design allows for seamless integration with various crushing and conveying systems.

Contact Us:

Ready to optimize your mining operations? Contact our team at Ava@zd-steels.com for a personalized consultation and quote on our mining crushing stations.

YOU MAY LIKE