2. Certification: CE (EN 1090 - 2), ISO 3834, 3rd - party test reports.

3. Custom: Track/wheel base, 800×1200 - 1500×2000mm feed, adj. output.

4. Delivery: 30 days std, 45 days non - std (incl. ocean freight).

5. Application: Mine/cwaste crushing, 200 - 800t/hour capacity.

6. Tech: Hydraulic folding conveyor, 62% time reduction.

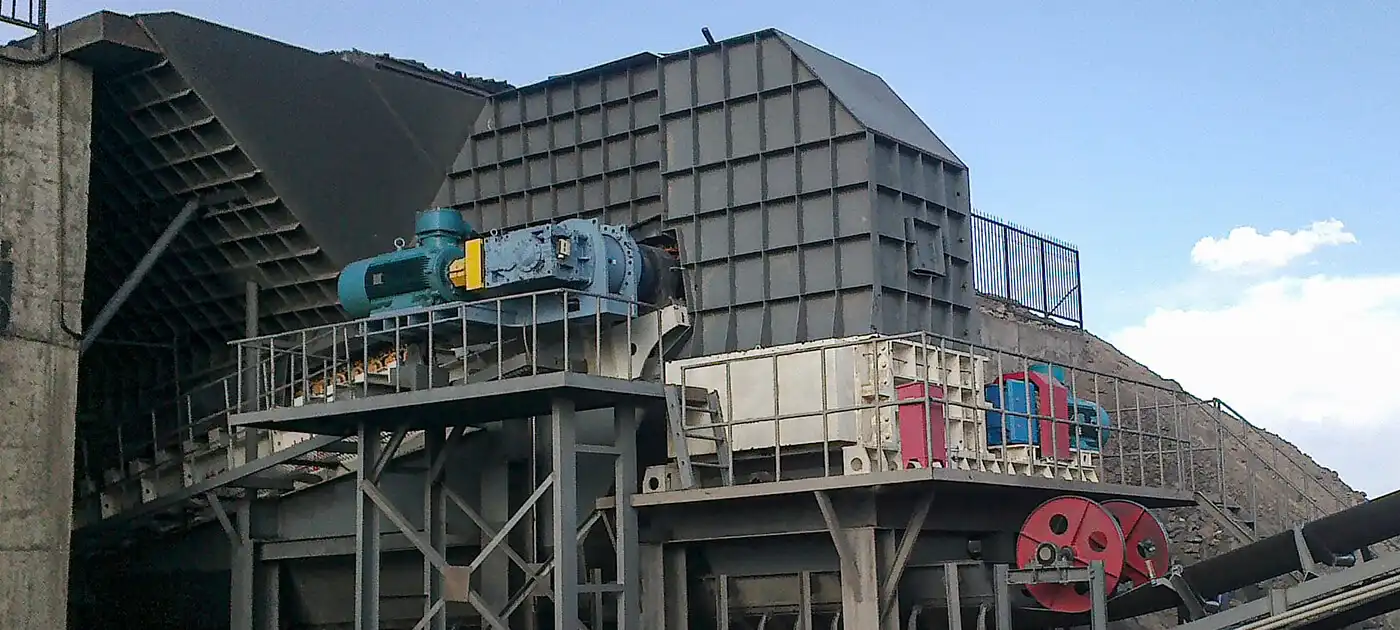

High-Frequency Crushing System Mining: Revolutionizing Mineral Processing

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of High-Frequency Crushing System Mining equipment. Our advanced systems offer unparalleled efficiency and precision in mineral processing, backed by our full-chain technical integration and R&D-driven standardization. With Zhongda's product System Mining solutions, you'll experience enhanced productivity, reduced operational costs, and superior end-product quality.

Product Description

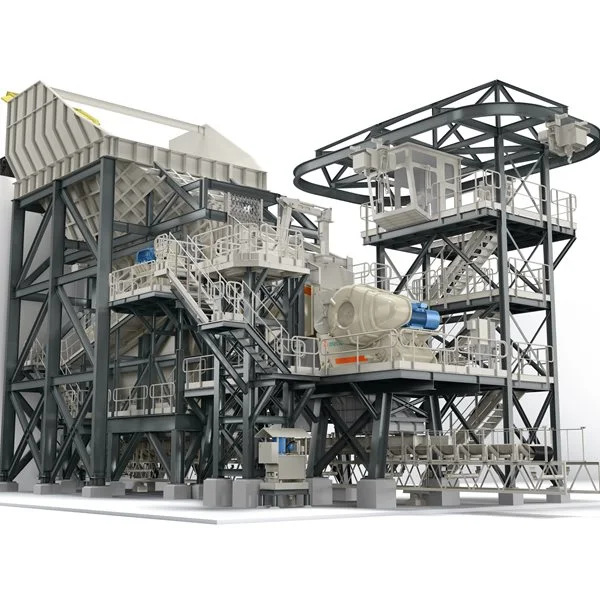

Our product equipment is designed to meet the demanding needs of large-scale mining operations, construction firms, and quarry operators. This state-of-the-art system utilizes high-frequency vibrations to efficiently crush and process a wide range of materials, including hard rock, ore, and construction waste. With customizable feed openings from 800×1200mm to 1500×2000mm and processing capacities of 200-800 tons/hour, our High-Frequency product solutions are adaptable to various project requirements.

Product Features

- Advanced hydraulic folding conveyor frame design, reducing relocation and installation time by 60%

- Modular assembly compatibility with jaw crushers and cone crushers

- Adjustable discharge system for precise output granularity control

- Track-based or wheel-based mobility options for enhanced site flexibility

- High-strength Q345B steel construction with NM400 wear-resistant plates for key components

Quality Control

At Zhongda, we prioritize quality at every stage of production. Our High-Frequency Crushing System Mining equipment undergoes rigorous testing and inspection, including:

- Adherence to ISO 9001/14001/45001 quality management systems

- Third-party nondestructive testing with comprehensive reports

- Compliance with CE Certification (EN 1090-2) and ISO 3834 Welding System standards

Why Choose Us?

- Industry-leading R&D capabilities and proprietary technologies

- Vertically integrated manufacturing with 60,000-ton annual capacity

- Proven track record in delivering over 60 landmark projects

- 70% client retention rate and 20-30% lead time reduction

- Compliance with global standards (EN 1090, AWS, JIS) for seamless integration

Production Process

Our product equipment is crafted with utmost precision and care. We employ state - of - the - art CNC machinery, which allows for highly accurate machining of every part. Automated welding lines are utilized to create seamless and durable joints, ensuring structural integrity. Precision fabrication techniques are applied throughout the manufacturing process, from raw material cutting to final assembly. This combination of advanced technologies guarantees not only consistent quality in each unit but also outstanding performance in real - world applications, making our products reliable choices for various industries.

OEM & ODM Services

Zhongda offers comprehensive OEM and ODM services for product equipment, tailored to your specific requirements:

- Customizable material specifications, including Q345B high-strength steel for the main structure and NM400 wear-resistant steel plates for key load-bearing parts

- Flexible base design options, including track-based or wheel-based mobility

- Adjustable feed opening sizes and output granularity to match your project needs

- Rapid delivery cycles: 30 days for standard models, 45 days for non-standard designs

- Full compliance with international standards and certifications

Project Cases

Our product solutions have been successfully implemented in numerous large-scale projects, including:

- Australian mining crushing stations, showcasing our global capabilities

- Jingha Expressway expansion, demonstrating versatility in construction applications

- Multiple quarry operations across China, improving efficiency and output quality

Certifications

- CE Certification (EN 1090-2)

- ISO 9001/14001/45001

- Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery

We ensure secure packaging and timely delivery of our product equipment, including specialized ocean freight packaging for international shipments.

FAQ

Q: What is the main advantage of the product?

A: High-frequency vibrations enable more efficient crushing and processing, leading to increased productivity and improved end-product quality.

Q: Can the system be customized for specific materials?

A: Yes, we offer customization options to optimize performance for various materials and project requirements.

Q: What after-sales support do you provide?

A: We offer comprehensive technical support, maintenance services, and spare parts supply to ensure optimal equipment performance.

Contact Us

Ready to revolutionize your mining operations with our High-Frequency Crushing System Mining solutions? Contact us at Ava@zd-steels.com for a personalized consultation and quote.

YOU MAY LIKE