2. Certification: ASME VIII, ISO 9001.

3. Custom: 2.5 - 6m dia., 40 - 150m len., waste heat opt.

4. Delivery: 60 days std, 75 days w/ special lining.

5. Application: Cement/ore processing, 3% - 5% tilt.

6. Warranty: ≤3mm/m straightness, 4 - year period.

High-Temperature Resistant Shell of Cement Rotary Kiln: Revolutionize Your Cement Production

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of High-Temperature Resistant Shell of Cement Rotary Kilns. Our advanced technology, precision engineering, and commitment to quality make us the preferred choice for cement manufacturers worldwide. Experience unparalleled durability, efficiency, and performance with our cutting-edge kiln shells.

Product Description:

Our product is designed to withstand the extreme conditions of modern cement production. Crafted from premium Q345R material with thicknesses ranging from 16-40mm, these shells offer superior strength and longevity. The high-temperature section features a chromium corundum castable lining, capable of resisting temperatures up to 1600°C. Our kiln shells are customizable with diameters from 2.5-6 meters and lengths of 40-150 meters, ensuring a perfect fit for your specific needs.

Product Features:

- Exceptional heat resistance up to 1600°C

- Customizable dimensions to suit various kiln sizes

- 42CrMo forged steel gears for optimal performance

- 3%-5% adjustable inclination for process optimization

- Optional waste heat recovery system for enhanced efficiency

- Cylinder straightness tolerance ≤3mm/m for precise operation

Quality Control:

At Zhongda, we prioritize quality at every stage of production. Our High-Temperature Resistant Shells undergo rigorous testing and inspection, adhering to ASME Sec VIII Pressure Vessel Certification and ISO 9001 Quality Management System standards. Our state-of-the-art facilities and experienced team ensure that each kiln shell meets the highest industry benchmarks.

Why Choose Us?

- Industry-leading expertise in steel structure engineering

- Vertically integrated capabilities from R&D to construction

- Advanced manufacturing facilities with 60,000-ton annual capacity

- Collaborative partnerships with top-tier design institutes

- Proven track record with over 60 landmark projects

- 70% client retention rate and 20-30% lead time reduction

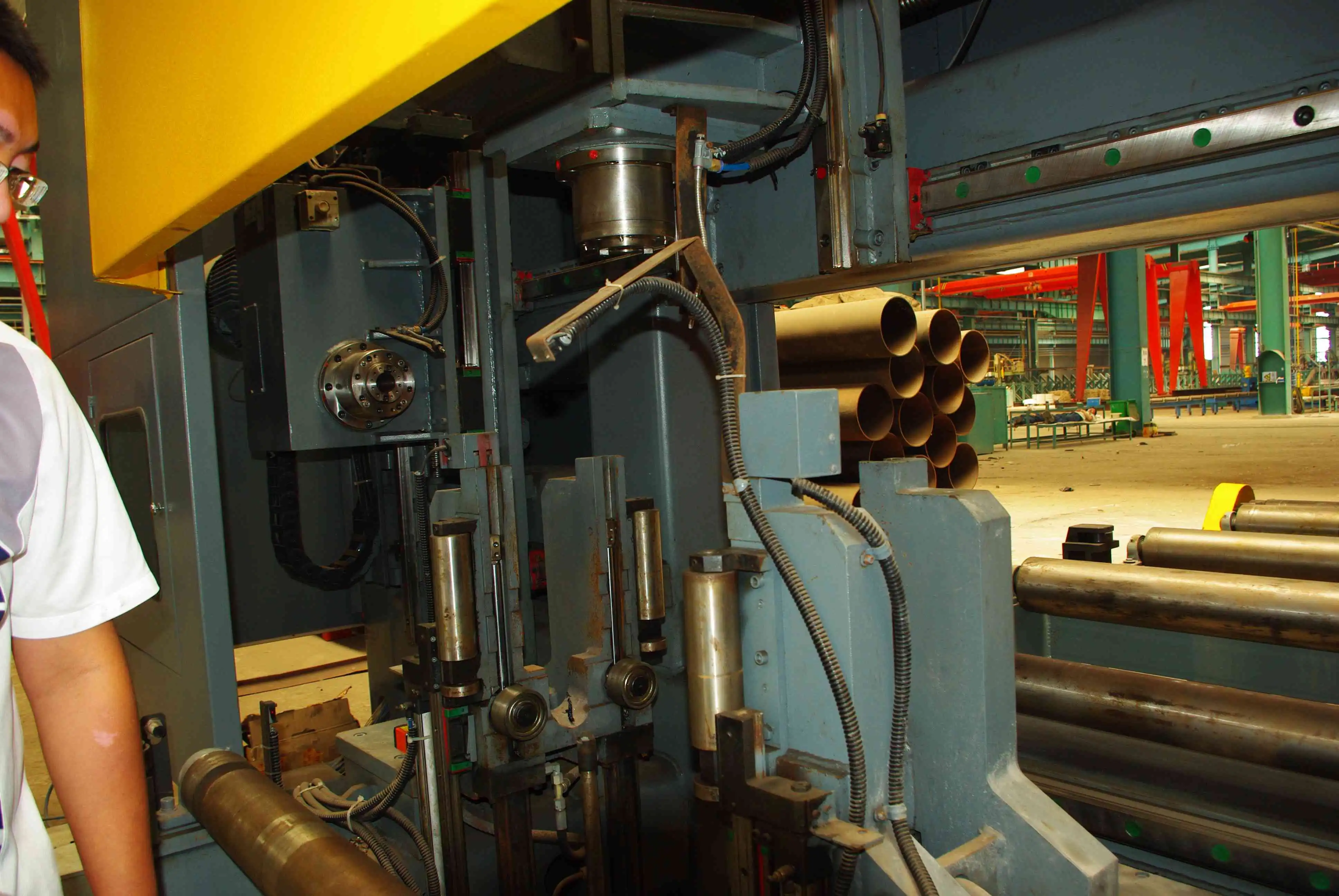

Production Process:

Our streamlined production process includes precision cutting, automated welding, and non-destructive testing, ensuring top-quality High-Temperature Resistant Shells for your cement rotary kilns.

OEM & ODM:

We offer comprehensive OEM and ODM services for High-Temperature Resistant Shell of Cement Rotary Kilns. Our team works closely with you to develop custom solutions that meet your specific requirements. Whether you need specialized dimensions, unique material compositions, or integrated heat recovery systems, we have the expertise to deliver. Our flexible manufacturing capabilities and quick turnaround times (60-75 days) ensure that your custom kiln shells are delivered on schedule, without compromising on quality or performance.

Project Cases:

Our High-Temperature Resistant Shells have been successfully implemented in numerous cement plants globally. For instance, we supplied a 5.2m diameter, 95m long kiln shell for a major cement manufacturer in Southeast Asia, resulting in a 15% increase in production efficiency and a 20% reduction in maintenance downtime. Another project in Central Europe saw our custom-designed kiln shell with integrated waste heat recovery system improve energy efficiency by 25%.

Certifications:

- ASME Sec VIII Pressure Vessel Certification

- ISO 9001 Quality Management System

- EN 1090 Certification for European markets

Packaging and Delivery:

We ensure secure packaging and timely delivery of your High-Temperature Resistant Shell, with standard lead times of 60-75 days depending on specifications.

FAQ:

Q: What is the warranty period for your High-Temperature Resistant Shells?

A: We offer a 3-year warranty on our kiln shells, demonstrating our confidence in their durability and performance.

Q: Can you provide shells for kiln maintenance and upgrades?

A: Absolutely! We specialize in both new installations and replacement shells for existing kilns, ensuring minimal disruption to your operations.

Q: How do your kiln shells contribute to energy efficiency?

A: Our precision-engineered shells, combined with optional waste heat recovery systems, can significantly reduce energy consumption in cement production.

Contact Us:

Ready to elevate your cement production with our High-Temperature Resistant Shell of Cement Rotary Kilns? Contact our expert team at Ava@zd-steels.com for personalized solutions and quotes.

YOU MAY LIKE