Optimizing Gas Tank Design for Maximum Pressure Resistance

Structural Considerations for Enhanced Pressure Resistance

When designing gas tanks for heavy-duty transport, structural optimization is paramount. The tank's shape plays a crucial role in distributing pressure evenly. Cylindrical designs are often preferred due to their inherent strength and ability to withstand high internal pressures. Additionally, incorporating reinforcing ribs or bands around the tank's circumference can significantly boost its pressure resistance capabilities. These structural elements help distribute stress and prevent localized weak points that could lead to failure under extreme conditions.

Material Selection for Durability and Strength

Choosing the right material is fundamental to ensuring gas tank pressure resistance. High-strength steels, such as Q345R, offer excellent yield strength ranging from 265 to 345 MPa for thicknesses up to 150mm. This makes them ideal for constructing robust gas tanks capable of withstanding the rigors of heavy-duty transport. The material's properties allow for thinner wall thicknesses while maintaining structural integrity, resulting in lighter yet stronger tanks. At Zhongda Steel, we specialize in ultra-thick plate cutting with precision of ±0.2mm, enabling us to fabricate tanks with optimal material utilization and performance.

Advanced Manufacturing Techniques for Superior Quality

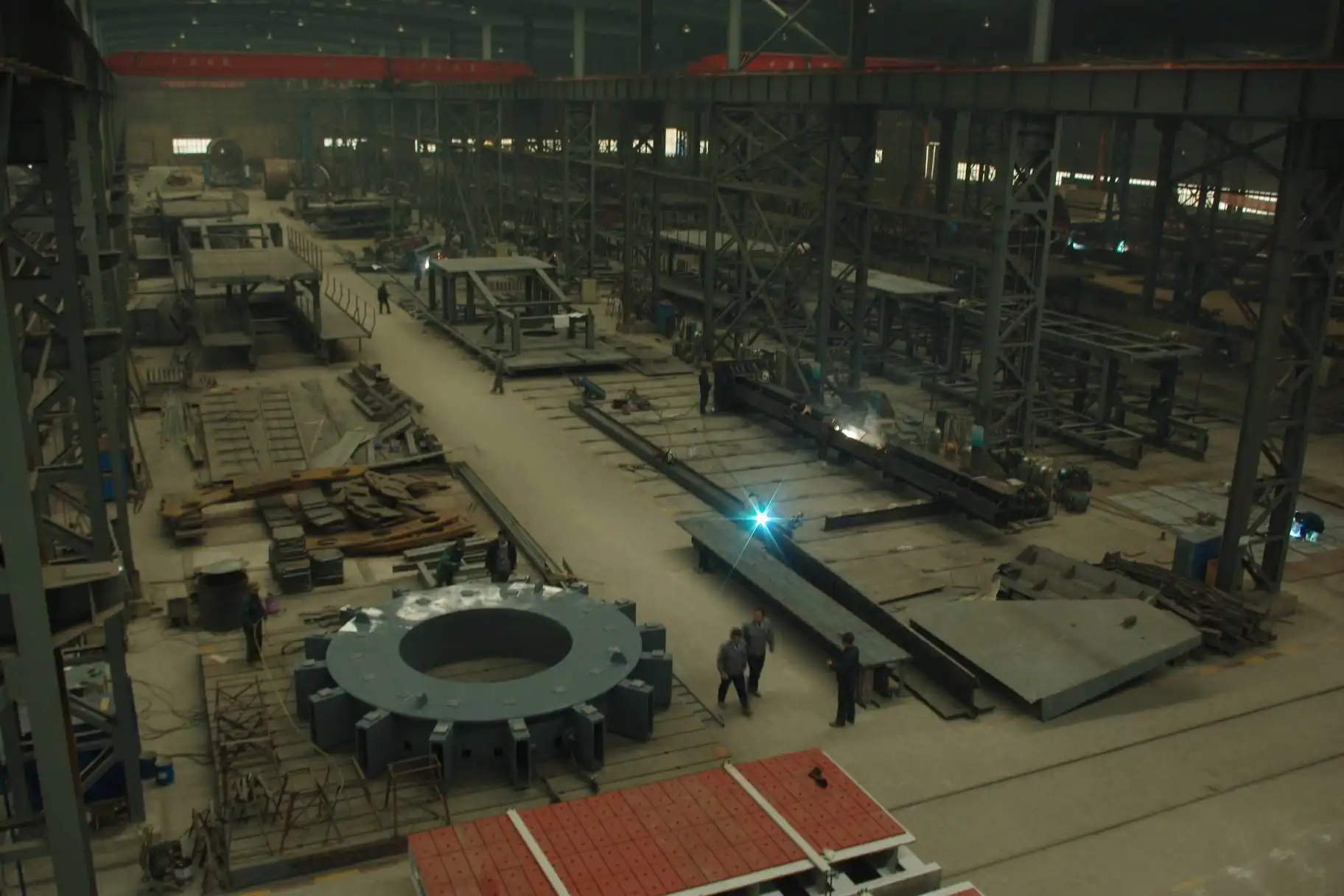

Employing cutting-edge manufacturing techniques is essential in producing gas tanks with exceptional pressure resistance. Precision welding, particularly in areas of high stress concentration, is critical. Utilizing automated welding processes ensures consistent, high-quality joints that can withstand extreme pressures. Furthermore, post-weld heat treatment can alleviate internal stresses, enhancing the tank's overall durability. Our state-of-the-art 120,000 m2 facility at Zhongda Steel is equipped with advanced machinery and skilled technicians to implement these sophisticated manufacturing methods, ensuring each gas tank meets the highest standards of quality and performance.

Implementing Rigorous Testing and Certification Protocols

Pressure Testing Methodologies for Gas Tanks

Comprehensive pressure testing is indispensable in validating gas tank pressure resistance. Hydrostatic testing, where tanks are filled with water and pressurized beyond their designed operating limits, is a common and effective method. This test helps identify any weak points or potential leaks in the tank structure. Additionally, cyclic pressure testing simulates the repeated pressurization and depressurization that tanks experience during normal operation, ensuring long-term reliability. At Zhongda Steel, we conduct thorough pressure tests on all our gas tanks, adhering to international standards and client-specific requirements to guarantee optimal performance and safety.

Non-Destructive Testing Techniques for Quality Assurance

Non-destructive testing (NDT) plays a vital role in ensuring gas tank integrity without compromising the structure. Techniques such as ultrasonic testing, radiographic inspection, and magnetic particle testing are employed to detect any internal defects, weld imperfections, or material inconsistencies that could affect pressure resistance. These methods allow for comprehensive quality control throughout the manufacturing process. Our facility is equipped with advanced NDT equipment, operated by certified technicians, ensuring that every gas tank meets the strictest quality standards before deployment in heavy-duty transport applications.

Certification and Compliance with Industry Standards

Adhering to industry standards and obtaining relevant certifications is crucial for ensuring gas tank pressure resistance and overall safety. Standards such as ASME Boiler and Pressure Vessel Code provide guidelines for design, fabrication, and inspection of pressure vessels, including gas tanks. Compliance with these standards not only ensures safety but also facilitates global acceptance of the tanks. As a globally certified leader with ISO 9001/14001/OHSAS 45001 and EN 1090 certifications, Zhongda Steel ensures that all gas tanks we produce meet or exceed international standards, providing our clients with confidence in the quality and reliability of our products.

Enhancing Long-Term Performance and Safety Measures

Corrosion Protection Strategies for Extended Lifespan

Implementing effective corrosion protection measures is essential for maintaining gas tank pressure resistance over time. Surface treatments such as galvanization or the application of specialized coatings can significantly enhance a tank's resistance to environmental factors. At Zhongda Steel, we leverage our expertise in -60°C Weathering Steel Anti-corrosion Technology to provide superior protection against corrosion, even in extreme conditions. This innovative approach not only extends the lifespan of gas tanks but also ensures consistent pressure resistance throughout their operational life.

Regular Inspection and Maintenance Protocols

Establishing a comprehensive inspection and maintenance regimen is crucial for preserving gas tank pressure resistance. Regular visual inspections can identify early signs of wear or damage, while periodic pressure tests can confirm ongoing structural integrity. Developing a detailed maintenance schedule, including checks on valves, fittings, and pressure relief devices, helps prevent potential issues before they escalate. Our team at Zhongda Steel provides guidance on best practices for inspection and maintenance, ensuring that gas tanks continue to perform optimally throughout their service life.

Innovative Safety Features and Monitoring Systems

Incorporating advanced safety features and monitoring systems can significantly enhance the pressure resistance and overall safety of gas tanks in heavy-duty transport. Pressure relief valves, emergency shut-off systems, and real-time pressure monitoring devices add layers of protection against overpressurization. Some cutting-edge designs include smart sensors that can detect and alert operators to potential issues before they become critical. At Zhongda Steel, we collaborate with clients to integrate these innovative safety features, leveraging our experience in BIM-driven prefabrication to create gas tanks that are not only pressure-resistant but also intelligent and responsive to potential hazards.

Conclusion

Ensuring gas tank pressure resistance in heavy-duty transport requires a multifaceted approach encompassing design optimization, material selection, rigorous testing, and ongoing maintenance. By leveraging advanced manufacturing techniques, implementing comprehensive quality assurance measures, and incorporating innovative safety features, we can create gas tanks that excel in pressure resistance and overall performance. At Zhongda Steel, we combine our expertise in precision steel solutions with cutting-edge technology to deliver gas tanks that meet the demanding requirements of heavy-duty transport applications, ensuring safety, reliability, and efficiency.

Contact Us

For expert assistance in designing and manufacturing pressure-resistant Q345R gas tanks for your heavy-duty transport needs, trust Zhongda Steel. Our team of skilled engineers and state-of-the-art facilities are ready to deliver custom solutions that prioritize safety and performance. Contact us today at Ava@zd-steels.com to discuss how we can help optimize your gas tank designs for maximum pressure resistance and reliability.