2. Certifications: ASME Sec VIII Div.1 and TPED 2010/35/EU.

3. Customization: Vertical/horizontal, 5 - 100m³ capacity, with valve/gauge modules.

4. Delivery: Standard tanks in 40 days, cryogenic ones in 60 days.

5. Application: LNG and industrial gas storage, - 196°C to +50°C.

6. Safety: Dual relief devices, 102% X - ray inspection.

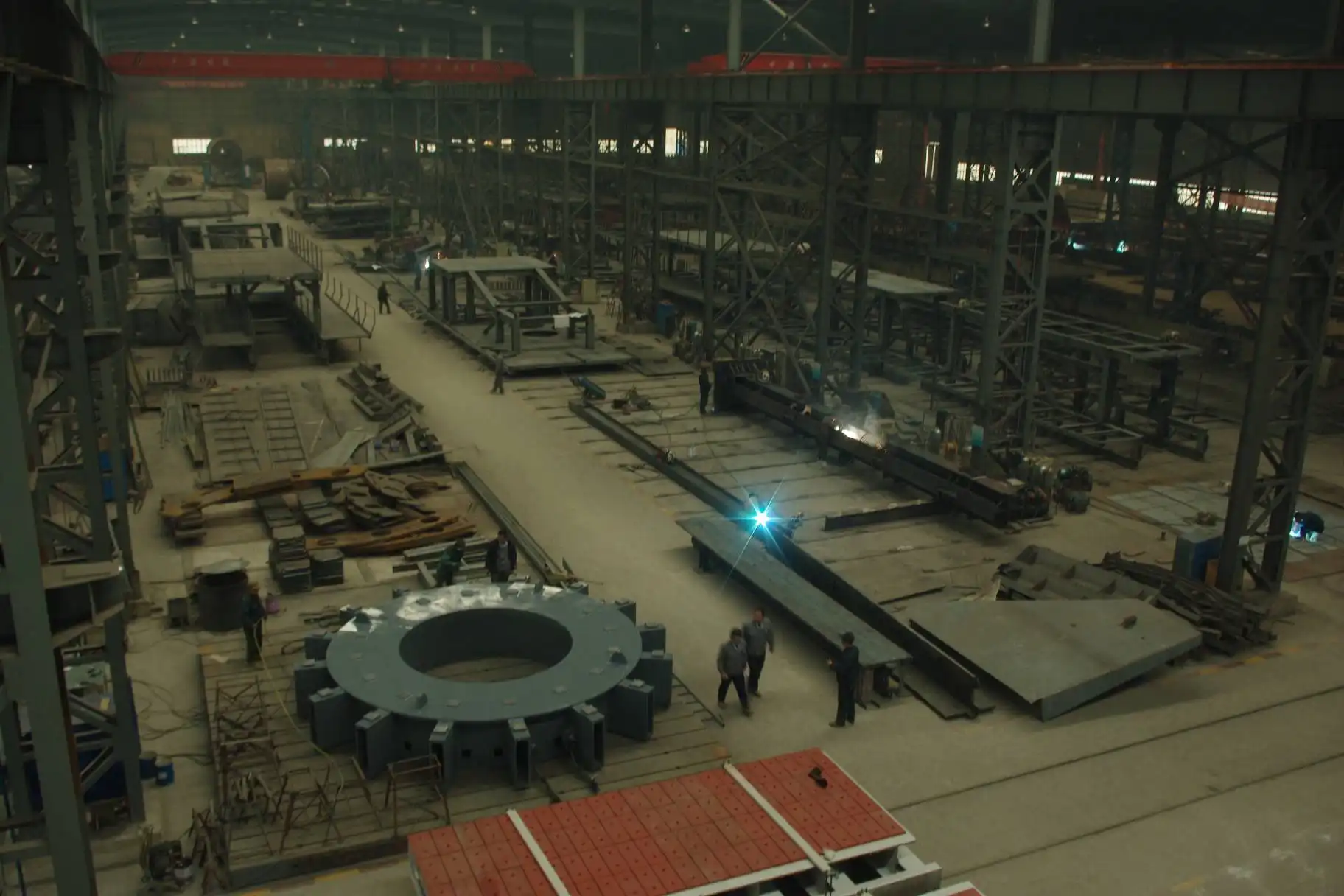

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Trusted Portable Compressed Gas Tank Manufacturer

As a leading Portable Compressed Gas Tank manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers superior quality, innovative design, and unmatched expertise. Our tanks meet the highest industry standards, ensuring safety and reliability for your gas storage needs.

Our products are engineered to excel in various industries, from manufacturing to healthcare. These tanks are designed for optimal performance, featuring:

- Durable Q345R steel construction (12-40mm thickness)

- Design pressure range of 1.6-3.0M

- Fully automated submerged arc welding for superior joint integrity

- Vertical and horizontal configurations (5-100m³ capacity)

- Operating temperature range of -196°C to +50°C

- Dual pressure relief devices for enhanced safety

- 100% X-ray inspection for structural integrity

- Compliance with ASME Sec VIII Div.1 and TPED 2010/35/EU standards

Whether you need LNG storage, industrial gas containment, or specialized solutions, our products deliver unparalleled performance and reliability.

Product Features:

- High-strength steel construction for durability

- Versatile design suitable for various gases and applications

- Advanced safety features, including dual pressure relief

- Customizable configurations to meet specific requirements

- Excellent thermal insulation for cryogenic applications

- Easy transport and installation for flexibility in use

Quality Control:

At Zhongda, quality is paramount. Our Portable Compressed Gas Tank undergo rigorous testing and inspection, including:

- 100% X-ray examination of welds

- Hydrostatic pressure testing

- Helium leak detection

- Dimensional checks and material verification

- Compliance with international standards and certifications

Why Choose Us?

- Our team exhibits industry - leading expertise in steel structure engineering, with in - depth knowledge across diverse project types.

- Boasting vertically integrated capabilities, we smoothly handle R&D, design, and construction to ensure seamless project flow.

- Equipped with advanced manufacturing facilities, our 60,000 - ton annual capacity enables large - scale production efficiently.

- We are committed to innovation and continuous improvement, constantly exploring new technologies and methods.

- With a proven track record, we've successfully completed over 60 landmark projects, demonstrating our reliability.

- Holding global compliance and certifications, we ensure seamless integration for projects worldwide.

Production Process:

- Material preparation and cutting

- Forming and shaping

- Automated welding

- Heat treatment

- Non-destructive testing

- Surface treatment and finishing

- Final inspection and certification

OEM & ODM Services:

Zhongda offers comprehensive OEM and ODM solutions for the products. Our capabilities include:

- Custom design services tailored to your specific requirements

- Material selection optimization for performance and cost-effectiveness

- Integration of specialized components or accessories

- Prototype development and testing

- Production scalability from small batches to high-volume orders

- Continuous engineering support and product improvements

- Compliance assistance with regional and international standards

By leveraging our expertise and state-of-the-art facilities, we ensure your custom products meet the highest quality standards while optimizing your operational efficiency.

Project Cases:

- Supplied 50 custom-designed LNG storage tanks for a major energy company's distribution network

- Developed high-pressure gas tanks for an international research facility's particle accelerator project

- Engineered and manufactured portable oxygen tanks for a national healthcare system's emergency response units

- Designed and produced specialized gas containment solutions for a global chemical manufacturer's production facilities

Certifications:

- ISO 9001:2015 Quality Management System

- ASME U-Stamp certification

- EN 1090 Execution Class 4 certification

- AWS D1.1 Structural Welding Code compliance

Packaging and Delivery:

- Custom protective packaging for safe transport

- Flexible shipping options (sea, air, or land)

- Typical delivery time: 40-60 days, depending on specifications

FAQ:

Q: Can you provide custom sizes for the products?

A: Yes, we offer customization services to meet your specific requirements.

Q: What is the warranty on your products?

A: We provide a standard 2-year warranty, with extended options available.

Q: Do you offer after-sales support and maintenance services?

A: Absolutely. Our team provides comprehensive technical support and maintenance assistance throughout the product lifecycle.

Contact Us:

Ready to elevate your gas storage solutions? Contact our expert team at Ava@zd-steels.com for personalized assistance and quotes on our Portable Compressed Gas Tank.

YOU MAY LIKE