2. Material: ASTM A709 Gr.50, Z35 Z - dir., resists tearing.

3. Anti - Corr: 160μm Zn spray, epoxy mica, polyurethane.

4. Load: Highway - I level, 100t max.

5. Inspection: MT + UT, full - node inspection.

6. Emergency: Detachable bridge, 200m in 51h.

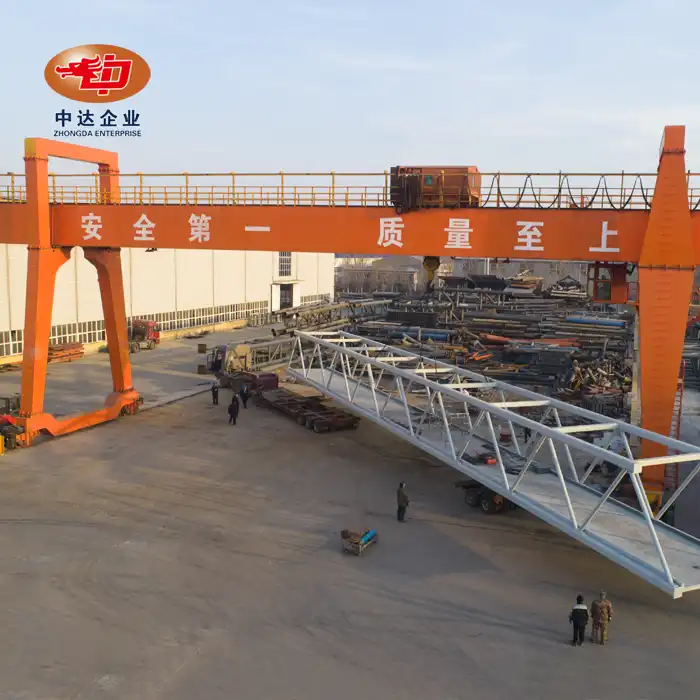

ASTM A709 Steel Truss Bridge: Engineered Excellence by Shenyang Zhongda

As a leading ASTM A709 Steel Truss Bridge manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled expertise in structural engineering. Our advanced fabrication techniques and stringent quality control ensure superior bridge solutions for your infrastructure projects.

Product Description

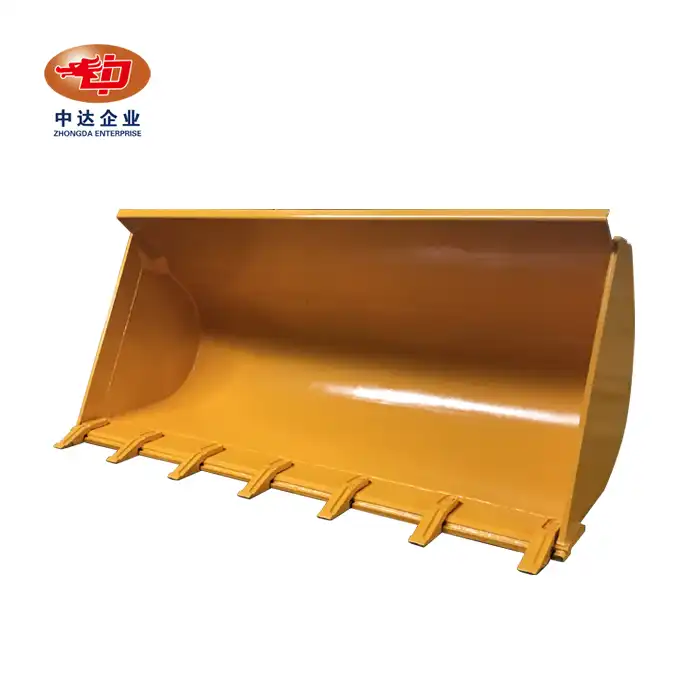

Our product combines cutting-edge engineering with robust materials to deliver exceptional performance and longevity. Designed to meet the demanding requirements of modern infrastructure, these bridges offer:

- High load-bearing capacity (up to 100 tons)

- Spans ranging from 30 to 150 meters

- Corrosion-resistant construction

- Rapid assembly and installation

- Customizable designs (Warren or Pratt Truss options)

- Compliance with Highway-I Level Load standards

Whether you're a government agency, construction firm, or engineering company, our ASTM A709 Steel Truss Bridge provide the ideal solution for your transportation infrastructure needs.

Product Features

- ASTM A709 Gr.50 steel with Z35 Z-direction performance

- Advanced anti-corrosion system (Thermal Spray Zinc + Epoxy Mica Iron + Polyurethane)

- Modular design for efficient transportation and assembly

- Detachable emergency bridge option for rapid deployment

Quality Control

At Shenyang Zhongda, we prioritize quality at every stage of production. Our rigorous quality control measures include:

- Full-node inspection using Magnetic Particle Testing (MT) and Ultrasonic Testing (UT)

- Compliance with ISO 9001, 14001, and 45001 standards

- Non-destructive testing throughout the fabrication process

- Strict adherence to ASTM A709 specifications

Why Choose Us?

- 60,000-ton annual production capacity

- Northeast China's largest steel workshop (50T crane capacity)

- Advanced CNC equipment for precision fabrication

- Expertise in complex project execution using BIM technology

- 70% client retention rate and 20-30% lead time reduction

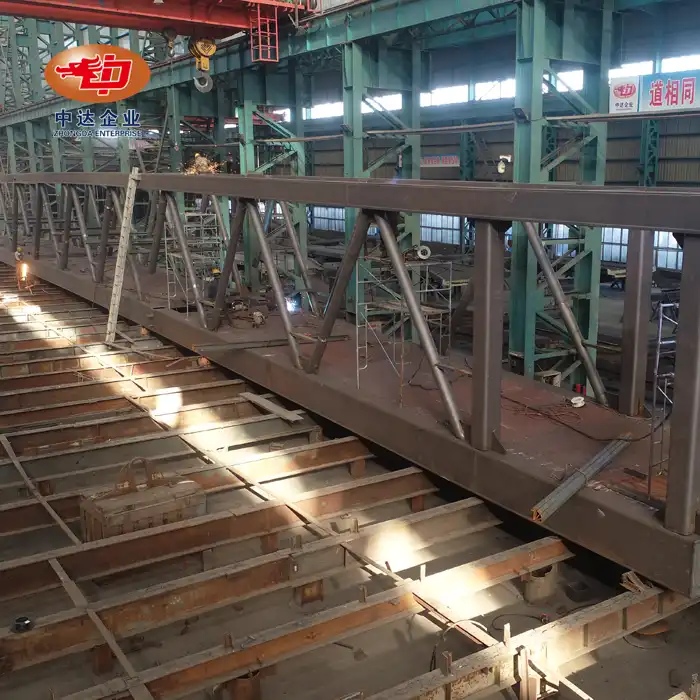

Production Process

Our streamlined production process ensures efficient and high-quality bridge fabrication:

- Design and engineering

- Material procurement and testing

- CNC cutting and drilling

- Welding and assembly

- Quality inspection

- Surface treatment and coating

- Packaging and shipping

OEM & ODM Services

Shenyang Zhongda offers comprehensive OEM and ODM services for the products. Our capabilities include:

- Customized bridge designs to meet specific project requirements

- Modular options for various span lengths and load capacities

- Tailored anti-corrosion solutions for diverse environmental conditions

- Rapid prototyping and design optimization

- Integration of advanced materials and technologies

- Collaborative engineering support throughout the project lifecycle

Our team of experienced engineers works closely with clients to develop innovative solutions that exceed expectations and deliver long-term value.

Project Cases

Our products have been successfully deployed in numerous high-profile projects, including:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion

- Multiple infrastructure projects for China Railway, CSCEC, and CCCC

- International projects in Belt and Road countries

These projects showcase our ability to deliver large-scale, complex bridge solutions while meeting stringent quality and timeline requirements.

Certifications

- ISO 9001, 14001, and 45001 certified

- Class I Steel Structure Professional Contracting Qualification

- Compliance with EN 1090, AWS, and JIS standards

Packaging and Delivery

At our company, we are dedicated to providing a comprehensive solution for your product component needs. We prioritize secure packaging, using high - grade materials and innovative techniques to safeguard each part during transit. Our delivery services are equally efficient, ensuring your components reach you in a timely manner. Moreover, understanding the diverse requirements of different projects, we offer options for both full and partial assembly. Whether you need a ready - to - install package or prefer to assemble components on - site, we can tailor our services to match your project's specific demands.

FAQ

Q: What is the typical lead time for a product?

A: Lead times vary depending on project complexity and size, but we typically deliver within 3-6 months.

Q: Can you provide on-site installation support?

A: Yes, we offer comprehensive installation and technical support services for all our bridge projects.

Q: How do you ensure compliance with local building codes?

A: Our team works closely with local authorities and conducts thorough research to ensure full compliance with all relevant regulations and standards.

Contact Us

Ready to discuss your ASTM A709 Steel Truss Bridge project? Contact our expert team at Ava@zd-steels.com for personalized solutions and competitive quotes.

YOU MAY LIKE

_1746242605579.webp)