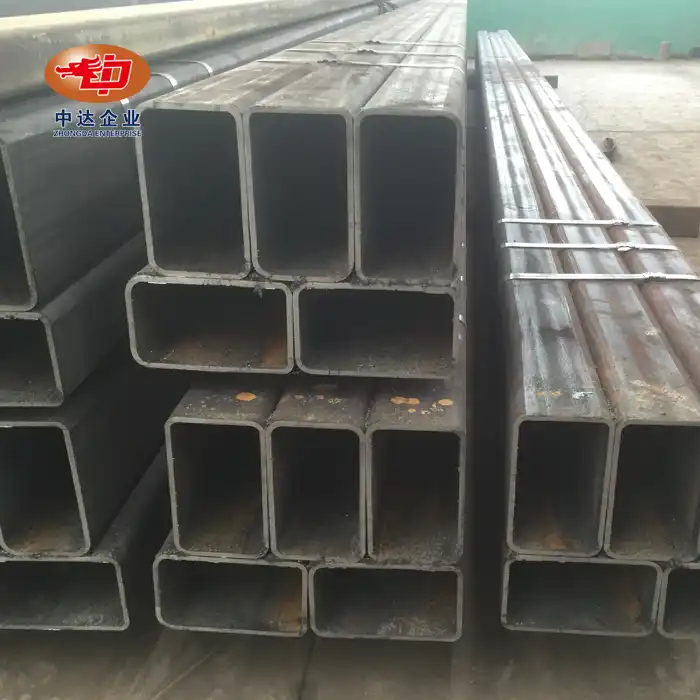

2. Material: ASTM A709 Gr.50, Z35 Z - dir., resists tearing.

3. Anti - Corr: 160μm Zn spray, epoxy mica, polyurethane.

4. Load: Highway - I level, 100t max.

5. Inspection: MT + UT, full - node inspection.

6. Emergency: Detachable bridge, 200m in 49h.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Demountable Warren-Type Steel Truss Bridge Manufacturer

As a leading Demountable Warren-Type Steel Truss Bridge manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled expertise, quality, and customization. Our products boast rapid assembly, superior durability, and cost-effectiveness, making us the top choice for infrastructure projects worldwide.

Product Description: Revolutionizing Infrastructure with Demountable Warren-Type Steel Truss Bridges

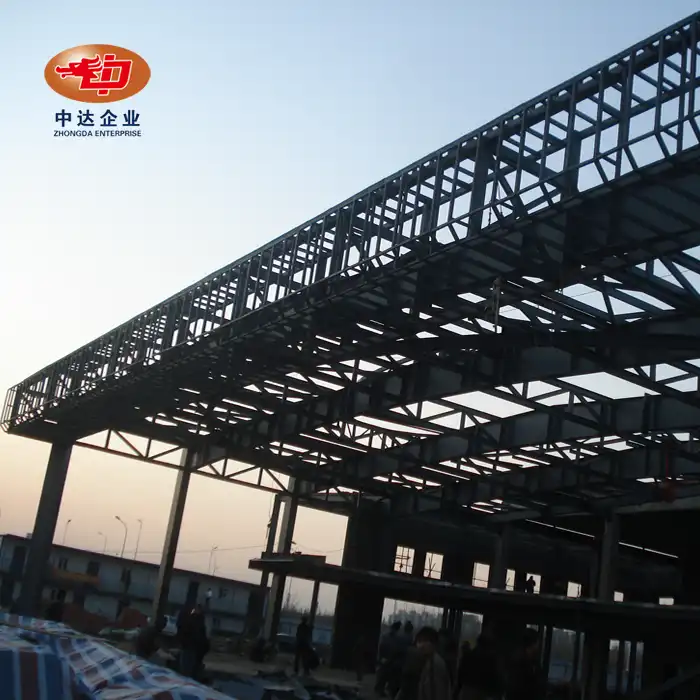

Our products are engineered for versatility and efficiency. These bridges feature a modular design, allowing for easy transportation and quick assembly in various terrains. With spans ranging from 30 to 150 meters, our bridges are ideal for both temporary and permanent installations. The Warren truss configuration ensures optimal load distribution, making these bridges perfect for heavy-duty applications in construction, military operations, and disaster relief efforts.

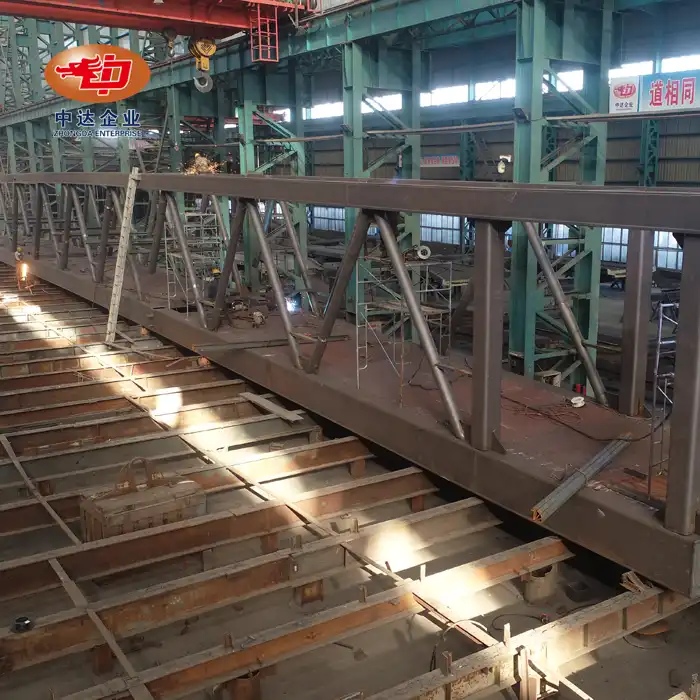

Crafted from high-grade ASTM A709 Gr.50 steel with Z35 Z-direction performance, our products resist lamellar tearing, ensuring long-term structural integrity. The innovative design allows for a maximum load capacity of 100 tons, meeting Highway-I Level Load standards.

Product Features:

- Rapid assembly and disassembly for flexible deployment

- Modular design for easy transportation and customization

- Spans of 30-150 meters to suit various project requirements

- High load capacity of up to 100 tons

- Durable ASTM A709 Gr.50 steel construction with Z35 performance

Quality Control:

At Zhongda, we prioritize quality in every product. Our rigorous quality control process includes:

- Full-node inspection using Magnetic Particle Testing (MT) and Ultrasonic Testing (UT)

- Adherence to ISO 9001/14001/45001 standards

- Comprehensive material certification and testing

- Strict compliance with international bridge construction regulations

Why Choose Us?

- Industry-leading expertise in product manufacturing

- Vertically integrated capabilities from R&D to construction

- Customization options to meet specific project needs

- Proven track record with over 60 landmark projects completed

- 70% client retention rate and 20-30% lead time reduction

Production Process:

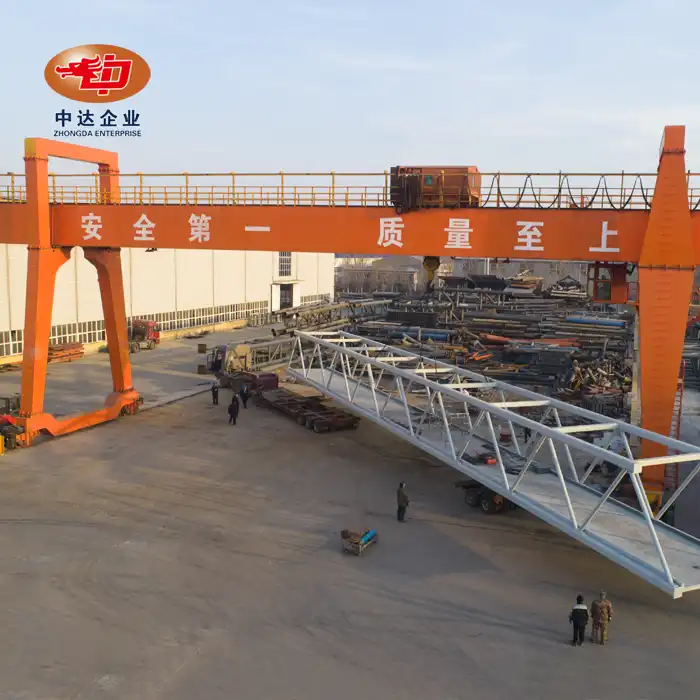

Our state-of-the-art facility, equipped with CNC ultra-thick plate cutting and automated welding lines, ensures precision manufacturing of every product component.

OEM & ODM Services:

Zhongda offers comprehensive OEM and ODM services for Demountable Warren-Type Steel Truss Bridge. Our team collaborates closely with clients to develop tailored solutions, including:

- Customized truss designs (Warren or Pratt)

- Specialized anti-corrosion treatments

- Detachable emergency bridge configurations

- BIM-based digital design for complex projects

- Integration of weathering steel technology for enhanced durability

Leveraging our R&D partnerships with top-tier institutes, we can adapt our products to meet your unique specifications and performance requirements.

Project Cases:

Our products have been successfully deployed in various challenging environments:

- 200-meter river crossing completed in 48 hours for emergency relief

- Multiple installations along the Belt and Road Initiative routes

- Temporary bridges for large-scale construction projects by China Railway and CSCEC

- Customized solutions for Australian mining operations

Certifications:

- ISO 9001/14001/45001

- Class I Steel Structure Professional Contracting Qualification

- Compliance with EN 1090, AWS, and JIS standards

Packaging and Delivery:

At our company, the secure packaging of our products is of utmost importance. Our skilled team uses high - quality materials and innovative techniques to safeguard each item, ensuring it withstands the rigors of transportation. Leveraging our in - depth expertise in international shipping and logistics, we coordinate with a vast network of carriers. This enables us to provide efficient delivery services, supporting global projects. Whether it's a complex infrastructure project in Asia or a large - scale industrial endeavor in the Americas, we guarantee that our products reach their destination on time and in perfect condition.

FAQ:

Q: What is the average assembly time for a product?

A: Assembly time varies based on span length and site conditions, but our efficient design allows for rapid deployment, with some projects completed in as little as 48 hours.

Q: Can your products be customized for specific environmental conditions?

A: Absolutely! We offer tailored solutions, including specialized anti-corrosion treatments and material selections to suit various environmental challenges.

Contact Us:

Ready to revolutionize your infrastructure projects with our Demountable Warren-Type Steel Truss Bridge? Contact us at Ava@zd-steels.com for expert consultation and quotations.

YOU MAY LIKE