2. Material: ASTM A709 Gr.50, Z35 Z - dir., resists tearing.

3. Anti - Corr: 160μm Zn spray, epoxy mica, polyurethane.

4. Load: Highway - I level, 100t max.

5. Inspection: MT + UT, full - node inspection.

6. Emergency: Detachable bridge, 200m in 50h.

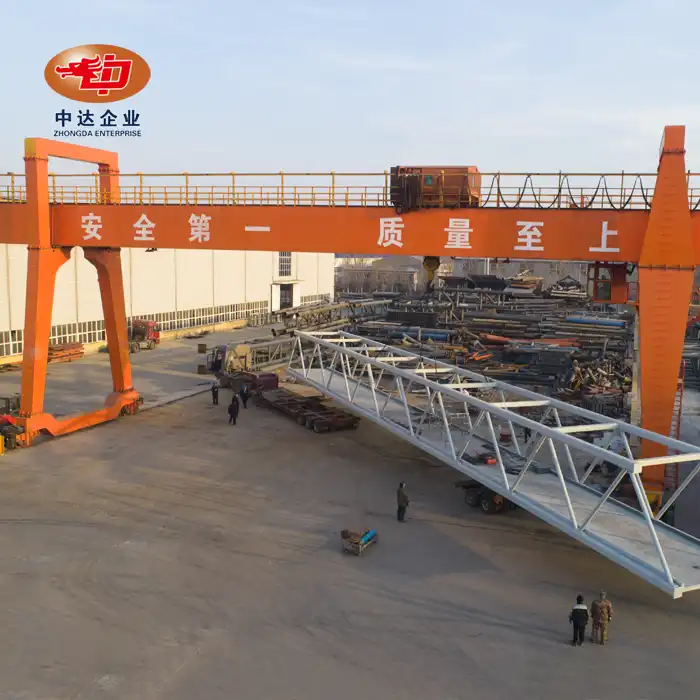

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Heavy-Duty Steel Truss Bridge Manufacturer

As a leading Heavy-Duty Steel Truss Bridge manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled expertise in bridge engineering. Our advanced fabrication techniques, stringent quality control, and customization capabilities set us apart in the industry.

Product Description: Heavy-Duty Steel Truss Bridge

Our product is engineered for maximum strength and durability, perfect for large-scale infrastructure projects. Designed to withstand extreme loads and environmental conditions, these bridges are ideal for spanning long distances over rivers, valleys, and highways. Our truss design optimizes material usage while ensuring superior load-bearing capacity, making it a cost-effective solution for government agencies and construction companies seeking reliable, long-lasting infrastructure.

Product Features:

- Customizable span lengths from 30 to 150 meters

- High load-bearing capacity up to 100 tons

- Modular design for rapid assembly and installation

- Choice of Warren or Pratt truss configurations

- Weathering steel option for reduced maintenance

- Seismic-resistant design for enhanced safety

Quality Control:

We implement rigorous quality control measures throughout the manufacturing process. Our Heavy-Duty Steel Truss Bridge undergo full-node inspection using advanced Magnetic Particle Testing (MT) and Ultrasonic Testing (UT) technologies. We adhere to international standards, including ISO 9001, to ensure every bridge meets the highest quality benchmarks.

Why Choose Us?

- Our 60,000 - ton annual production capacity equips us to handle large - scale orders, efficiently manufacturing high - quality products year - round.

- The state - of - the - art 50T crane capacity workshop enables seamless handling of heavy - duty materials for diverse production needs.

- With vertically integrated capabilities from R&D to construction, we ensure seamless project flow and high - quality outcomes at every stage.

- Collaborations with top - tier design institutes and universities fuel innovation, bringing fresh ideas and expertise to our projects.

- Having completed over 60 landmark projects, our proven track record showcases our reliability and excellence in project execution.

- A 70% client retention rate and 20 - 30% lead time reduction reflect our commitment to client satisfaction and operational efficiency.

Production Process:

- Design and Engineering

- Material Procurement

- Fabrication and Welding

- Quality Inspection

- Surface Treatment

- Pre-assembly and Testing

- Packaging and Shipping

OEM & ODM Services:

We offer comprehensive OEM and ODM services tailored to your specific project requirements. Our modular design approach allows for customization in truss type, span length, and load capacity. We use ASTM A709 Gr.50 steel with Z35 Z-direction performance to resist lamellar tearing. Our advanced anti-corrosion solution includes thermal spray zinc, epoxy mica iron intermediate coat, and polyurethane topcoat for extended bridge lifespan.

For emergency situations, we offer a detachable Emergency Bridge option capable of completing a 200-meter river crossing in just 48 hours, demonstrating our commitment to innovation and rapid response.

Project Cases:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion project

- Multiple heavy bridges for China Railway, CSCEC, and CCCC

Certifications:

- ISO 9001/14001/45001

- Class I Steel Structure Professional Contracting Qualification

- EN 1090, AWS, and JIS standards compliance

Packaging and Delivery:

At our company, we prioritize the safety and punctuality of component deliveries. Our experts craft secure packaging using top - notch materials to shield all components from potential damage during transit. What's more, we offer tracking services throughout the shipping process, allowing you to monitor the progress of your order in real - time. Our dedicated logistics team, well - versed in transportation coordination, ensures a seamless journey from our facility to your project site. This comprehensive approach gives you peace of mind, knowing your components are in safe hands and will arrive precisely when needed.

FAQ:

Q: What is the typical lead time for a product?

A: Lead times vary based on project specifications, but we generally achieve 20-30% faster delivery compared to industry standards.

Q: Can you provide on-site technical support during installation?

A: Yes, we offer comprehensive technical support, including on-site assistance during bridge assembly and installation.

Contact Us:

Ready to start your Heavy-Duty Steel Truss Bridge project? Contact our expert team at Ava@zd-steels.com for a personalized consultation and quote. Let's build the future of infrastructure together!

YOU MAY LIKE

_1746242605579.webp)