2. Material: ASTM A709 Gr.50, Z35 Z - dir., resists tearing.

3. Anti - Corr: 160μm Zn spray, epoxy mica, polyurethane.

4. Load: Highway - I level, 100t max.

5. Inspection: MT + UT, full - node inspection.

6. Emergency: Detachable bridge, 200m in 48h.

Steel Standard Truss Bridges: Durable, Customizable Solutions by Shenyang Zhongda

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Steel Standard Truss Bridges. Our advantages include full-chain technical integration, R&D-driven innovation, and expertise in mega-project execution, ensuring top-quality bridges that meet your infrastructure needs.

Product Description:

Our products combine strength, durability, and adaptability to meet diverse project requirements. Designed for highway and railway applications, these bridges offer superior load-bearing capacity and longevity. With spans ranging from 30 to 150 meters, our truss bridges are ideal for crossing rivers, valleys, and challenging terrains. We utilize high-grade steel and advanced fabrication techniques to ensure optimal performance under various environmental conditions. Our bridges are engineered to withstand heavy traffic, extreme weather, and seismic activities, making them a reliable choice for critical infrastructure projects.

Product Features:

- Customizable span lengths (30-150 meters)

- High load-bearing capacity (up to 100 tons)

- Modular design for rapid assembly

- Choice of Warren or Pratt truss configurations

- ASTM A709 Gr.50 steel with Z35 Z-direction performance

- Advanced anti-corrosion coating system

Quality Control:

We implement rigorous quality control measures throughout the manufacturing process. Our steel undergoes strict material certification, and we employ full-node inspection using Magnetic Particle Testing (MT) and Ultrasonic Testing (UT). This comprehensive approach ensures the structural integrity and longevity of our products.

Why Choose Us?

Zhongda offers unparalleled expertise in Steel Standard Truss Bridges. Our vertically integrated capabilities, from R&D to construction, ensure seamless project execution. We've successfully delivered over 60 landmark projects, maintaining a 70% client retention rate. Our innovative approach, including BIM-based design and lifecycle management, sets us apart in the industry.

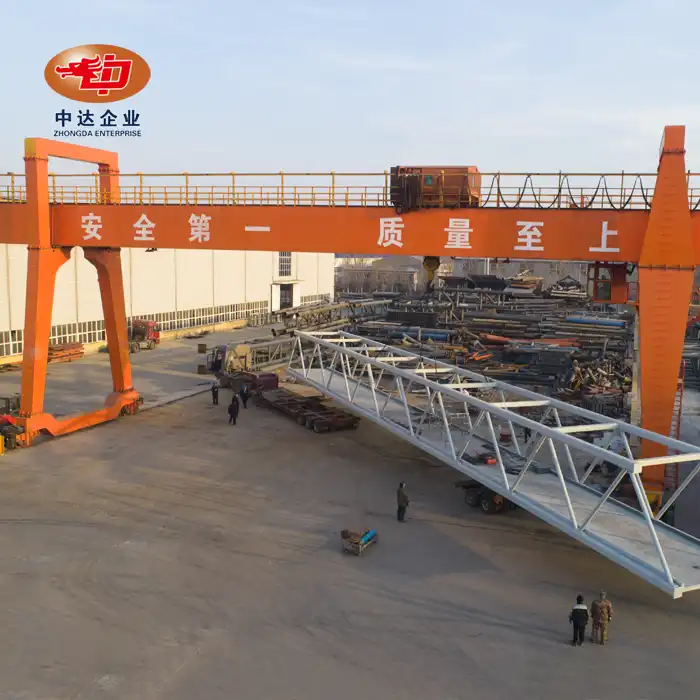

Production Process:

Design > Fabrication > Quality Inspection > Anti-corrosion Treatment > Assembly > Delivery

OEM & ODM:

We offer extensive customization options for our products to meet your specific project requirements:

1. Modular Design:

-

Choose between Warren Truss or Pratt Truss configurations

-

Customize span range from 30 to 150 meters

-

Benefit from rapid assembly features

2. Material and Corrosion Protection:

-

ASTM A709 Gr.50 steel with Z35 Z-direction performance

-

Three-layer anti-corrosion system: Thermal Spray Zinc, Epoxy Mica Iron, and Polyurethane Topcoat

3. Load Capacity and Emergency Solutions:

- Standard Highway-I Level Load capacity, up to 100 tons

- Optional detachable emergency bridge design for rapid deployment

Our engineering team works closely with clients to develop tailored solutions, ensuring each bridge meets specific site conditions and project goals.

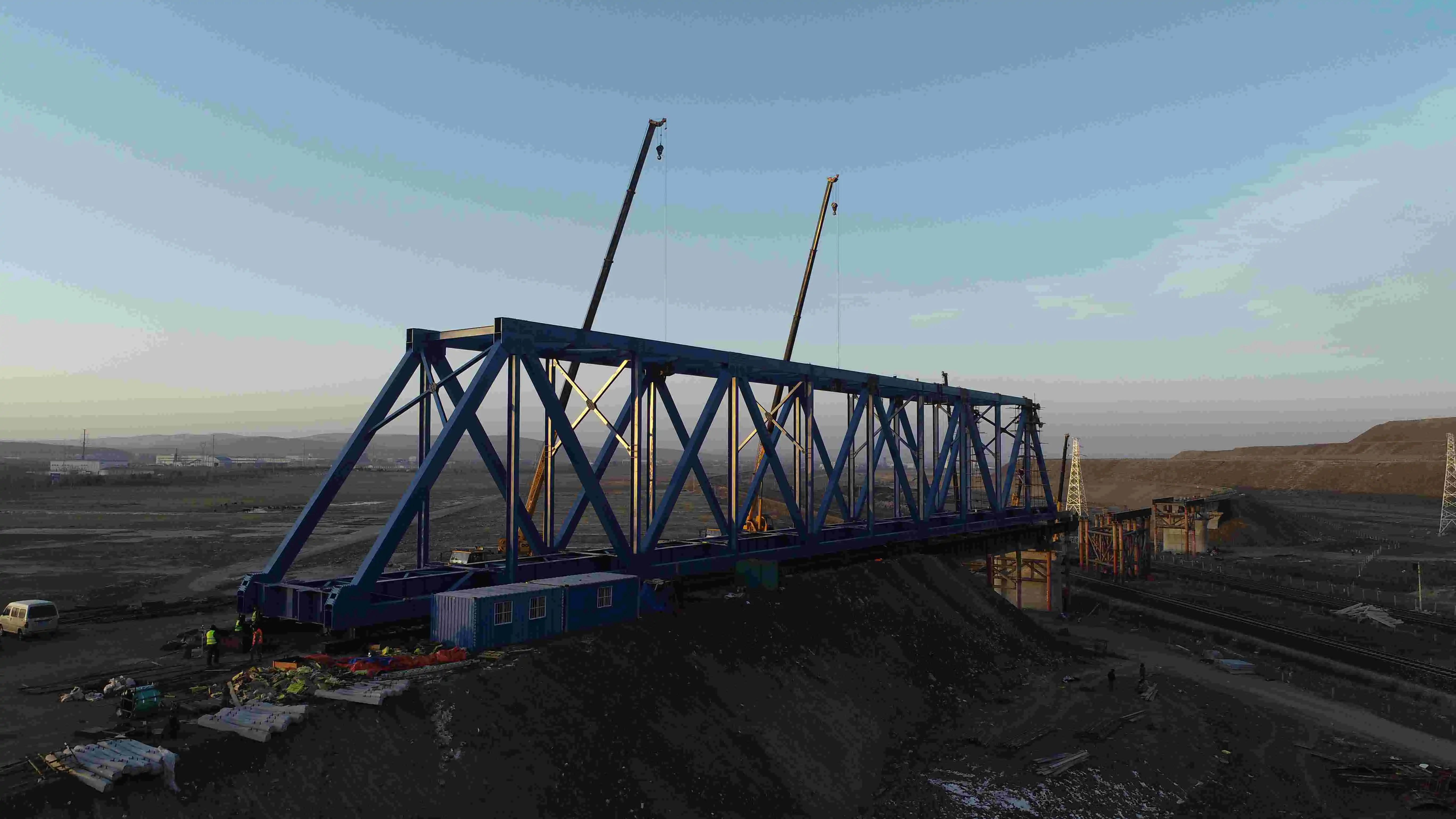

Project Cases:

- Shenyang Dongta Cross-Hunhe River Bridge: 18,000-ton steel truss bridge showcasing our capability in heavy-load structures.

- Jingha Expressway Expansion: Multiple steel truss bridges demonstrating our expertise in transportation infrastructure.

- International Projects: We've supplied bridge components for global projects, including Australian mining operations, highlighting our versatility and compliance with international standards.

Certifications:

ISO 9001, ISO 14001, ISO 45001, EN 1090, AWS, JIS standards compliant

Packaging and Delivery:

We prioritize the safety of your goods during transit by offering custom packaging. Our team designs protective wrappings tailored to each item's shape and fragility. Paired with this, our global logistics support ensures on - time delivery. We coordinate with a vast network of carriers, optimizing routes and schedules, so your products reach their destination promptly, no matter where in the world that may be.

FAQ:

Q: What is the typical lead time for a Steel Standard Truss Bridge?

A: Lead times vary based on project complexity, but we typically achieve 20-30% faster delivery compared to industry standards.

Q: Can you provide on-site assembly support?

A: Yes, our experienced team offers comprehensive on-site assembly and installation guidance.

Q: How do your bridges perform in extreme weather conditions?

A: Our bridges are engineered to withstand extreme temperatures, high winds, and heavy snow loads, ensuring year-round reliability.

Contact Us:

Ready to discuss your Steel Standard Truss Bridges project? Contact us at Ava@zd-steels.com for expert consultation and tailored solutions.

YOU MAY LIKE