2. Certifications: ASME Sec VIII Div.1 and TPED 2010/35/EU.

3. Customization: Vertical/horizontal, 5 - 100m³ capacity, with valve/gauge modules.

4. Delivery: Standard tanks in 40 days, cryogenic ones in 60 days.

5. Application: LNG and industrial gas storage, - 196°C to +50°C.

6. Safety: Dual relief devices, 100% X - ray inspection.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Q345R Gas Tank Manufacturer & Supplier

As a leading Q345R Gas Tank manufacturer, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers superior quality, customization, and full-chain integration. Our advanced facilities and R&D-driven approach ensure top-tier products for your industrial needs.

Q345R Gas Tank: Product Description

Our product is the ultimate solution for safe and efficient gas storage in various industries. Crafted from high-strength Q345R steel, these tanks offer exceptional durability and reliability for storing LNG, industrial gases, and other pressurized substances. With a capacity range of 5-100m³ and design pressures of 1.6-3.0MPa, our products meet diverse industrial requirements.

Key Features :

- Our product features superior Q345R steel construction with thickness ranging from 12 - 40mm, providing excellent durability and strength.

- It offers both vertical and horizontal configurations, allowing for easy adaptation to different installation and space requirements.

- The operating temperature range spans from -196°C to +50°C, making it suitable for diverse and extreme environmental conditions.

- Fully automated submerged arc welding is employed, guaranteeing optimal joint strength and consistent quality throughout the structure.

- Dual pressure relief devices are installed, significantly enhancing safety by effectively managing pressure fluctuations.

- We conduct 100% X - ray inspection, ensuring the structural integrity of every component for reliable performance.

Quality Control

We maintain rigorous quality standards throughout the production process of our Q345R Gas Tank:

- Adherence to ASME Sec VIII Div.1 and TPED 2010/35/EU standards

- Comprehensive material testing and traceability

- Advanced non-destructive testing techniques

- Strict quality control at every production stage

Why Choose Us?

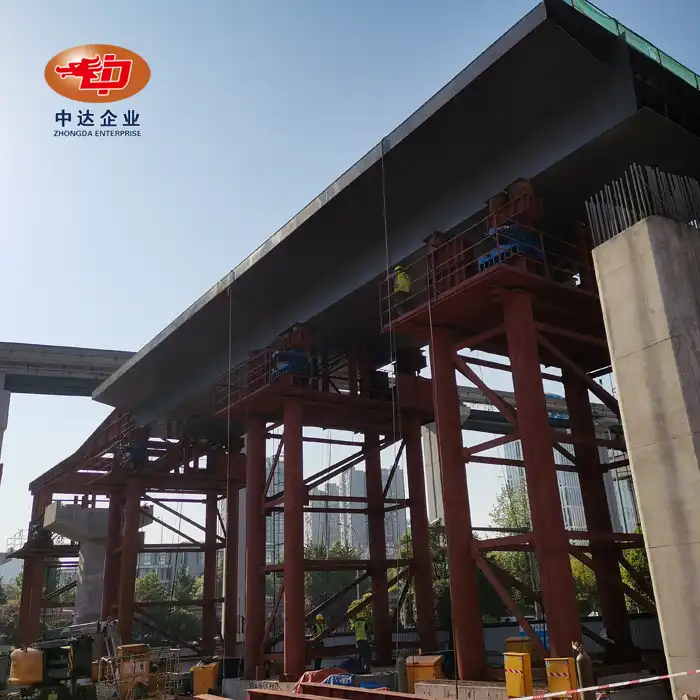

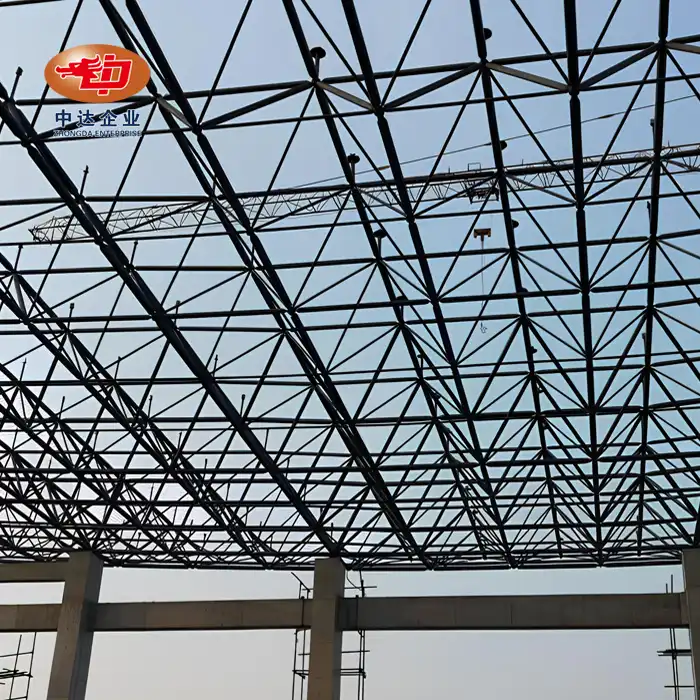

- Our team showcases industry - leading expertise in steel structures, having mastered complex designs and construction techniques over years.

- We provide a wide range of customization options, adapting every aspect to precisely meet your unique project requirements.

- With full - chain integration from design to installation, we ensure seamless coordination at each stage of the project.

- Our proven track record includes successful collaborations with major clients in the oil & gas and chemical industries, demonstrating reliability.

- Despite offering competitive pricing, we maintain high - quality standards, using top - tier materials and strict quality control.

Production Process

Our state-of-the-art facility employs cutting-edge technology for precision fabrication:

- Material selection and testing

- CNC cutting and forming

- Automated welding

- Heat treatment

- Non-destructive testing

- Surface treatment and painting

OEM & ODM Services

We offer comprehensive OEM and ODM services for products, catering to your unique specifications:

- Custom design options (vertical/horizontal, capacity, pressure ratings)

- Material selection guidance

- Integrated accessory modules (safety valves, pressure gauges)

- Specialized coatings for corrosion resistance

- Tailored testing and certification packages

- Technical consultation throughout the project lifecycle

Our flexible manufacturing capabilities and engineering expertise ensure that your product meets exact requirements while optimizing cost-efficiency and performance.

Project Cases

- LNG Storage Facility, Liaoning Province:

- 50 units of 100m³ vertical products

- Custom-designed for -162°C operation

- Completed ahead of schedule, enhancing client's production capacity

- Industrial Gas Supplier, Jiangsu Province:

- 30 units of 50m³ horizontal products

- Integrated pressure control systems

- Reduced client's operational costs by 15%

Certifications

- ASME Sec VIII Div.1 Certification

- TPED 2010/35/EU Transport Qualification

- ISO 9001:2015 Quality Management System

Packaging and Delivery

- Secure packaging for safe transportation

- Standard delivery time: 40 days

- Expedited options available for urgent needs

FAQ

Q: What is the typical lifespan of a product?

A: With proper maintenance, our products can last 20-30 years.

Q: Can you provide installation services for products?

A: Yes, we offer comprehensive installation and commissioning services globally.

Q: Are your products suitable for cryogenic applications?

A: Absolutely. Our tanks are designed and tested for temperatures as low as -196°C.

Contact Us

Ready to elevate your gas storage capabilities? Contact our expert team at Ava@zd-steels.com for a personalized Q345R Gas Tank solution tailored to your requirements.

YOU MAY LIKE