2. Certification: ISO 14329 welding, 3D stress report.

3. Custom: 1 - 5m³ cap., side teeth/cleaning edge opts.

4. Delivery: 15 days std, 20 days rock - reinf.

5. Application: Mining/port use, Cat/Komatsu compat.

6. Warranty: 6 - month edge repl., lifetime body weld.

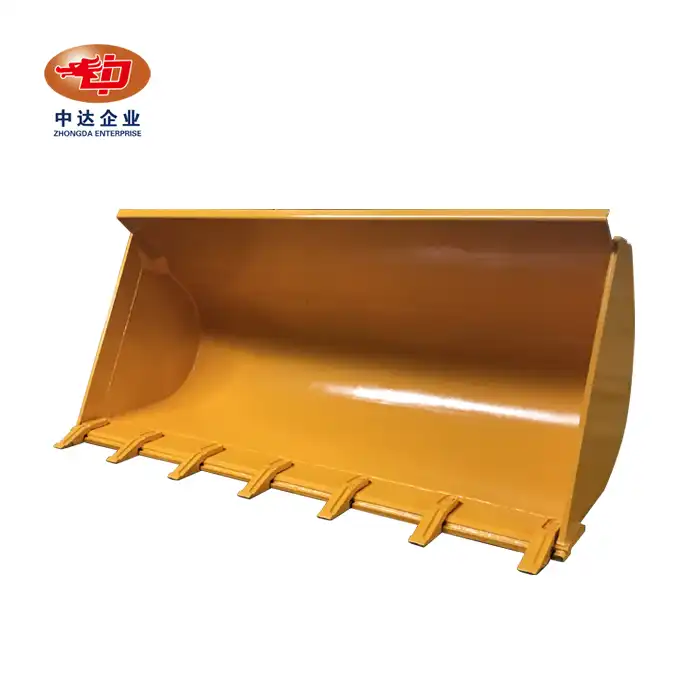

Hardox 450 Loader Buckets: Unmatched Durability for Heavy-Duty Applications

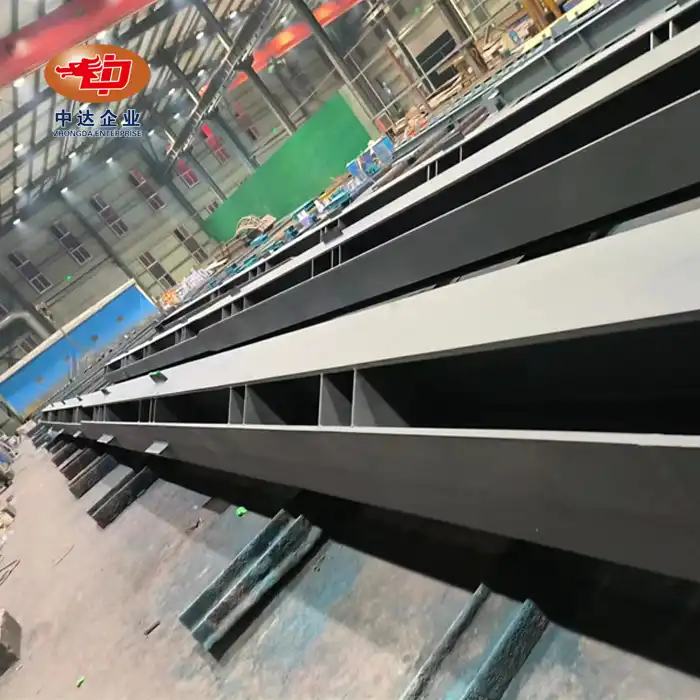

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of premium Hardox 450 Loader Buckets. Our state-of-the-art facilities and expertise in steel fabrication allow us to deliver superior quality buckets that outperform and outlast the competition.

Product Description:

Our products are engineered for ultimate performance in the most demanding environments. Crafted from genuine Hardox 450 wear-resistant steel, these buckets offer exceptional durability and resistance to abrasion, impact, and wear. Whether you're in mining, construction, or waste management, our loader buckets are designed to boost your productivity and reduce downtime.

Key Features of Our products:

- Exceptional wear resistance for extended service life

- High strength-to-weight ratio for improved payload capacity

- Customizable designs to fit various loader models and applications

- Reinforced structure for enhanced durability in harsh conditions

- Optimized geometry for improved material flow and reduced spillage

Quality Control: Ensuring Excellence in Every Bucket

At Zhongda, quality is paramount. Our Hardox 450 Loader Buckets undergo rigorous testing and inspection processes, including:

- Non-destructive testing of all welds

- 3D stress analysis for optimal structural integrity

- Dimensional checks to ensure perfect fit and compatibility

- Hardness testing to verify material properties

- Final inspection and documentation for full traceability

Why Choose Zhongda's Hardox 450 Loader Buckets?

- 60,000-ton annual production capacity ensures timely delivery

- Advanced CNC machinery for precise fabrication

- In-house R&D team for continuous product improvement

- Comprehensive after-sales support and spare parts availability

- Proven track record with major mining and construction companies

Production Process:

Design → Cutting → Forming → Welding → Heat Treatment → Machining → Quality Control → Finishing

OEM & ODM Services: Tailored Solutions for Your Needs

We offer full customization options for our products:

- Capacity ranging from 1 to 5 m³ to suit your equipment

- Custom wear packages for specific material handling requirements

- Integration of side teeth or cleaning edge attachments

- Compatibility with all major loader brands (CAT, Komatsu, etc.)

- Specialized designs for unique applications (e.g., high-temperature materials)

Our engineering team works closely with clients to develop bespoke solutions that maximize efficiency and productivity in their specific operations.

Project Cases: Proven Performance Worldwide

- Supplied 50 custom products to a major Australian iron ore mine, resulting in a 30% increase in bucket lifespan.

- Developed specialized buckets for a Canadian oil sands operation, reducing maintenance downtime by 40%.

- Delivered a fleet of heavy-duty buckets to a Chinese quarry, improving productivity by 25% due to increased payload capacity.

Certifications:

ISO 9001, ISO 14001, ISO 45001, AWS Certified Welding Fabricator

Packaging and Delivery:

When shipping your items overseas, we prioritize the safety of your goods above all else. Our team of experts crafts secure packaging solutions, using high - quality, durable materials to safeguard your products from potential damage during transit. We understand that time is of the essence for your business operations. That's why our standard lead time stands at a reliable 15 - 20 days. But if you're in a hurry, we also offer expedited options. Our logistics partners work closely with us to ensure that your shipment is prioritized, allowing you to receive your items even sooner, without compromising on the quality of the packaging or the delivery service.

FAQ:

Q: What makes Hardox 450 ideal for loader buckets?

A: Hardox 450 offers an optimal balance of hardness and toughness, providing excellent wear resistance without compromising structural integrity.

Q: Can you provide replacement wear parts?

A: Yes, we offer a full range of wear parts, including cutting edges and wear liners, all manufactured from genuine Hardox steel.

Q: Do you offer on-site bucket inspections and maintenance services?

A: We provide comprehensive after-sales support, including on-site inspections and maintenance recommendations to maximize your bucket's lifespan.

Contact Us:

Ready to upgrade your fleet with high-performance Hardox 450 Loader Buckets? Contact our sales team at Ava@zd-steels.com for a personalized quote and expert advice on selecting the perfect bucket for your application.

YOU MAY LIKE

_1746242570299.webp)

_1746242605579.webp)