2. Certification: CE (EN 12336), TUV safety report.

3. Custom: 4 - 15m dia., EPB/Slurry modes.

4. Delivery: 6 - 8 months std, FOB/CIF terms.

5. Application: Metro/culvert work, 80mm/min thrust.

6. After - Sales: 48 - hour resp., free cutter repl.

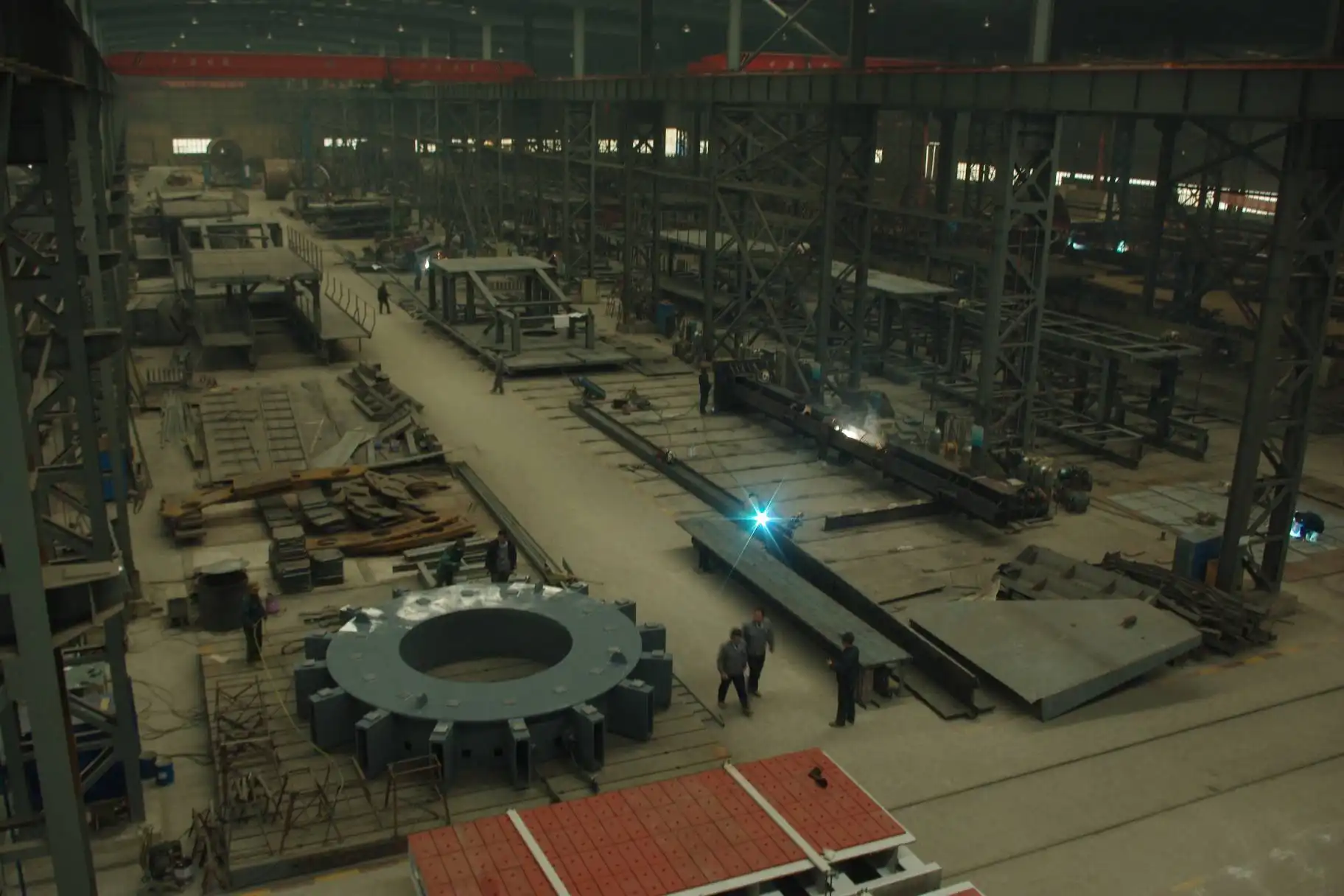

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Special Shield Machine Manufacturer

As a leading special shield machine manufacturer and supplier, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers cutting-edge tunneling solutions. Our products combine advanced technology, robust construction, and unparalleled efficiency, making us the top choice for major infrastructure projects worldwide.

Product Description:

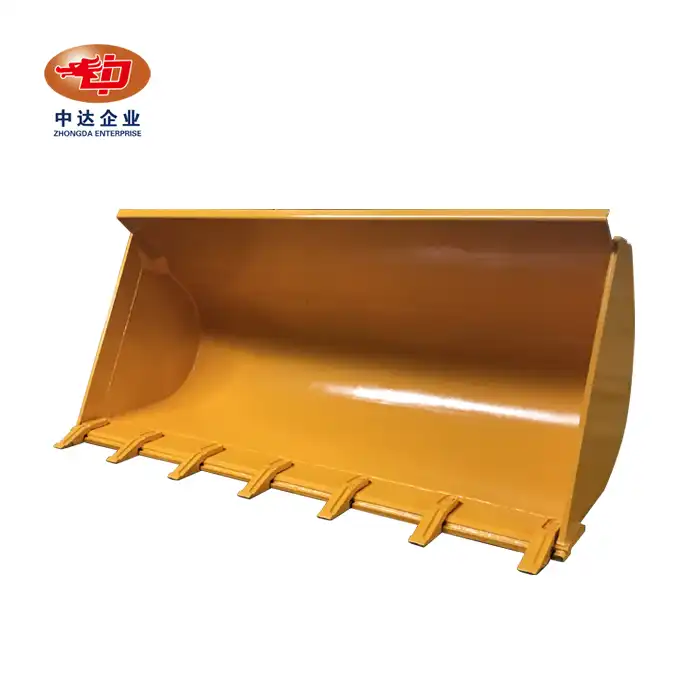

Our state-of-the-art products are designed to meet the most demanding tunneling challenges. These powerful excavation systems utilize advanced cutting technology and precise pressure control to efficiently bore through various soil and rock conditions. Our products can be customized to diameters ranging from 4 to 15 meters, suitable for a wide array of projects from metro tunnels to large-scale underground infrastructure development.

Key features of our products include:

- Adaptable cutting head designs for diverse geological conditions

- Advanced soil conditioning systems for optimal performance

- Real-time monitoring and control systems for enhanced safety

- Modular design for easy transport and assembly

- High-efficiency excavation rates to accelerate project timelines

Quality Control

At Zhongda, we maintain stringent quality control measures throughout the manufacturing process of our special shield machine. Our ISO 9001-certified quality management system ensures consistent production standards. Each machine undergoes rigorous testing and inspection before delivery, guaranteeing performance and reliability in the field.

Why Choose Us?

- 60,000-ton annual production capacity

- Advanced R&D capabilities and proprietary technologies

- Experienced team of engineers and technicians

- Comprehensive after-sales support and maintenance services

- Proven track record with over 60 landmark projects completed

Production Process

Our products are manufactured using a state-of-the-art production line, including CNC ultra-thick plate cutting, 3-axis CNC drilling systems, and automated welding lines, ensuring precision and efficiency.

OEM & ODM Services

We offer customized OEM and ODM solutions for the products, tailoring our products to meet your specific project requirements. Our engineering team works closely with clients to develop bespoke designs, incorporating cutting-edge technologies and materials.

Key specifications for customization include:

- Cutterhead Body: Q460C Low Alloy Steel (Thickness 80-120mm)

- Cutters: Tungsten Carbide Inserts

- Thrust Cylinder Pressure: 35-40MPa

- Customizable diameter: 4-15 meters

- Optional Modes: Earth Pressure Balance (EPB) / Slurry Shield Modes

Project Cases

Our products have been successfully deployed in numerous high-profile projects, including:

- Shenyang Metro Line 4: 6.5m diameter EPB shield machine for complex urban tunneling

- Jingha Expressway Expansion: 12m diameter slurry shield machine for challenging soil conditions

- International projects: Custom-designed products for tunneling projects in Southeast Asia and the Middle East

Certifications

Our products are CE certified (EN 12336) and have obtained TUV Shield Machine Safety Assessment Reports, ensuring compliance with international safety and quality standards.

Packaging and Delivery

At our company, we offer comprehensive solutions for product transportation. We ensure secure packaging using high - quality materials, protecting your products from any potential damage during transit. Our global shipping services cover destinations worldwide. For standard models, we have a well - defined delivery cycle of 6 - 8 months. We also provide flexible shipping terms such as FOB Shanghai, where the goods are transferred to the buyer at the Shanghai port, and CIF to the destination port, which includes cost, insurance, and freight. This allows you to choose the option that best suits your business needs.

FAQ

Q: What is the maximum thrust speed of your products?

A: Our machines can achieve a maximum thrust speed of 80mm/min, ensuring rapid excavation progress.

Q: Do you provide after-sales support for your products?

A: Yes, we offer comprehensive after-sales support, including a 48-hour global engineer response time and free first-time cutter replacement.

Contact Us

Ready to elevate your tunneling projects with our advanced special shield machine? Contact our sales team at Ava@zd-steels.com for personalized quotes and technical consultations.

YOU MAY LIKE

_1746242570299.webp)

_1746242605579.webp)