What Materials Are Used for Outdoor Sound Barriers and How to Choose?

When it comes to tackling noise pollution in bustling urban areas, sprawling highways, or industrial zones, selecting the right materials for outdoor sound barriers is paramount. These structures, often referred to as noise walls or acoustic fences, are crafted from a variety of materials, including metal (like galvanized steel or aluminum), transparent options (such as polycarbonate or acrylic), PVC, and composite blends (think fiberglass paired with rock wool). Choosing the ideal material hinges on your project's unique needs - be it durability, aesthetics, or noise reduction efficacy. At Zhongda Steel, we leverage cutting-edge technology and a wealth of experience to guide you through this decision, ensuring your noise mitigation solution is both effective and visually appealing.

Understanding the Core Materials for Noise Mitigation

Metal Options: Strength and Longevity

Metal remains a cornerstone in the construction of sound barriers, prized for its robustness and endurance. Galvanized steel, with its corrosion-resistant zinc coating, stands out as a top choice, especially in harsh industrial zones or along highways exposed to the elements. Aluminum, while lighter, offers similar resilience with the added perk of being rust-proof, making it ideal for coastal regions. These materials excel in longevity, often lasting decades with minimal upkeep, and can be perforated to enhance sound absorption when paired with internal insulating layers. Their strength also ensures they withstand high wind pressures, a critical factor for installations in open, windy areas.

Transparent Materials: Balancing Light and Aesthetics

In settings where natural light or visual appeal is a priority - such as residential neighborhoods or scenic bridges - transparent materials like polycarbonate and acrylic shine. Polycarbonate is particularly valued for its impact resistance, making it a safe choice in areas prone to debris or vandalism. Acrylic, on the other hand, offers superior clarity, lending an elegant, unobtrusive look to urban landscapes. Both materials can be treated with UV-resistant coatings to prevent yellowing or degradation over time, ensuring they remain both functional and attractive. While not as soundproof as metal, their ability to let light through makes them a popular choice for visually sensitive projects.

Composite Solutions: Advanced Noise Absorption

For environments plagued by high-frequency noise, such as railways or construction sites, composite materials offer a sophisticated solution. These sound barriers often combine a perforated outer layer - typically aluminum or steel - with an inner core of sound-absorbing substances like centrifugal glass wool or rock wool. This layered approach traps and dissipates sound waves, achieving impressive noise reduction coefficients. The versatility of composites allows for customization, such as varying the perforation rate or integrating eco-friendly materials, making them adaptable to a wide range of environmental and regulatory demands. Their modular nature also simplifies installation, a boon for large-scale infrastructure projects.

Key Factors in Selecting the Right Sound Barrier Material

Environmental Conditions and Durability Needs

The environment in which your noise wall will stand plays a pivotal role in material selection. In areas with extreme weather - be it scorching heat, freezing cold, or high humidity - durability is non-negotiable. Metal barriers, especially those treated with weathering steel or UV-resistant coatings, excel in such conditions, resisting corrosion and fading even after years of exposure. For projects in milder climates or urban settings, transparent materials might suffice, offering a balance of durability and aesthetic appeal. Consider also the wind pressure in your area; highway installations, exposed to gusts, require materials that can endure forces up to 1.2kN/㎡, a standard metal barriers readily meet.

Noise Reduction Performance and Design

The efficacy of a sound barrier hinges on its ability to reduce noise, measured by metrics like the noise reduction coefficient (NRC) and decibel (dB) reduction. Composite barriers, with their sound-absorbing cores, often achieve NRC values up to 0.81, making them ideal for high-decibel environments like industrial parks or rail transit zones. Metal sound barriers, when perforated and layered, also perform admirably, offering vertical noise reduction up to 25dB(A). Transparent materials, while less effective at soundproofing, can be combined with metal frames to boost performance without sacrificing light transmission. Design elements, such as arc tops, can further enhance functionality by minimizing wind whistle effects in rail applications.

Customization and Integration into Projects

Every project is unique, and the ability to tailor your noise mitigation solution is a significant advantage. Modular designs, ranging from 2 to 6 meters in length, allow for seamless integration into diverse settings, from sprawling expressways to compact industrial hubs. Customization extends to aesthetics, with over 200 color options available on the RAL chart, as well as the integration of logos or bespoke designs. Material thickness can be adjusted - typically between 80mm and 140mm - to meet specific noise reduction or structural requirements. Advanced services, like BIM-based design, ensure your sound barrier aligns perfectly with your project's architectural and engineering plans, enhancing both efficiency and outcome.

Why Partnering with Experts Elevates Your Noise Mitigation Strategy?

Leveraging Innovation for Superior Results

Choosing the right materials is only part of the equation; partnering with a company that drives innovation ensures your project stands out. At Zhongda Steel, our R&D team continuously pushes the boundaries of noise mitigation technology, developing solutions like weathering steel for extreme durability and eco-friendly material alternatives for sustainability. Our products, featuring modular designs and high-performance composites, are rigorously tested to meet global standards, including EU CE Certification (EN 14388) and SGS weather resistance benchmarks. This commitment to innovation translates into barriers that not only reduce noise but also enhance safety, with features like integrated fall prevention nets.

Proven Success in Real-World Applications

Experience matters, and a track record of successful projects speaks volumes. Zhongda Steel has delivered over 60 landmark projects worldwide, from the 10km Jingha Expressway expansion to the 5km arc-top barriers at Shenyang Airport. These installations showcase our ability to tailor solutions to diverse needs, whether it's mitigating noise in industrial parks or enhancing safety along rail lines. Our 70% client retention rate underscores our reliability, while our ability to slash lead times by 20-30% ensures your project stays on schedule. These real-world applications highlight how our expertise translates into tangible benefits for developers, designers, and manufacturers globally.

Comprehensive Support from Concept to Completion

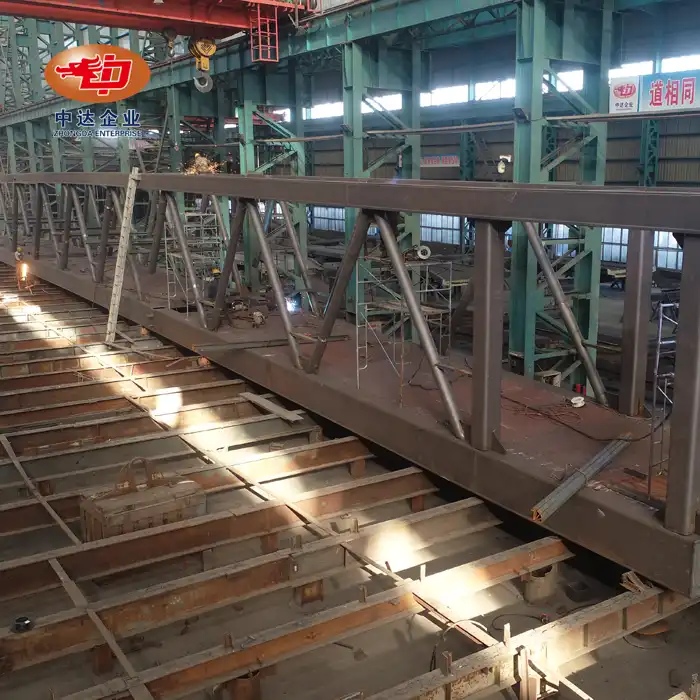

A outdoor sound barrier project is a complex endeavor, requiring more than just quality materials. Zhongda Steel offers end-to-end support, from initial design through to on-site installation. Our OEM and ODM services allow for rapid prototyping, including 3D-printed models for client approval, ensuring your vision is realized with precision. We also provide on-site training and installation support, minimizing disruptions and maximizing efficiency. With a modern 120,000 m² facility equipped with CNC ultra-thick plate cutting and automated welding lines, we guarantee micron-level accuracy and swift production, making us a trusted partner for projects of any scale, anywhere in the world.

Conclusion

Selecting the right materials for outdoor sound barriers is a blend of science, aesthetics, and practicality. Whether you prioritize durability with metal, aesthetics with transparent panels, or advanced noise absorption with composites, understanding your project's unique needs is key. Zhongda Steel stands ready to guide you, offering innovative, customizable solutions backed by global expertise and rigorous quality standards. Make noise pollution a thing of the past with a partner committed to excellence.

Contact Us

Ready to elevate your noise mitigation strategy? Trust Zhongda Steel to deliver cutting-edge outdoor sound barriers tailored to your project's demands. Benefit from our full-chain technical integration, rapid prototyping, and global compliance expertise. Contact us today at Ava@zd-steels.com to explore how we can transform your vision into reality.

References

Smith, J. (2020). Acoustic Engineering: Principles of Noise Control. London: Technical Press.

Brown, L. (2019). Materials Science in Urban Infrastructure. New York: Engineering Insights.

Patel, R. (2021). Sustainable Noise Mitigation Strategies. Sydney: EcoBuild Publications.

Kim, H. (2018). Advances in Composite Materials for Sound Absorption. Seoul: Innovation Tech.

Garcia, M. (2022). Designing Effective Sound Barriers for Highways. Madrid: Infrastructure Solutions.

Nguyen, T. (2020). Environmental Noise Control: A Global Perspective. Hanoi: Green Engineering Press.