2. Seismic: Passed 8 - degree test, 20mm thick joint ribs.

3. Customization: Adjustable cross - section, pre - installed tubes.

4. Anti - corrosion: Hot - dip galvanizing (275g/㎡), epoxy coating (200μm).

5. Certifications: EN 1090 - 2 EXC3, third - party load report.

6. Delivery: Standard in 30 days (7 - day curing), complex in 45 days (7 - day curing).

8. Applications: High - speed railway stations, super high - rise cores, large - span facilities.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Trusted Factory-Prefabricated SRC Composite Beam Manufacturer & Supplier

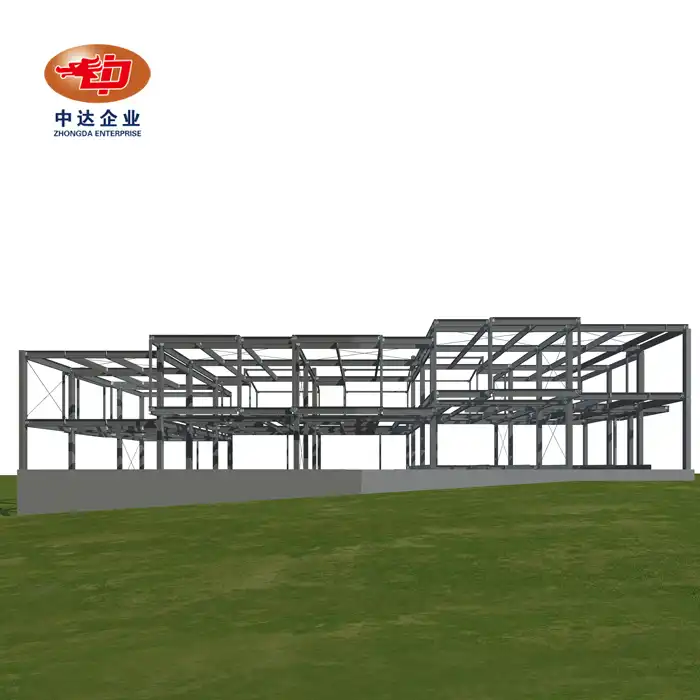

As a leading manufacturer of Factory-Prefabricated SRC Composite Beams, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled quality, efficiency, and customization. Our advanced prefabrication technology ensures superior structural integrity and faster project completion for your construction needs.

Product Description: Factory-Prefabricated SRC Composite Beam

Our products combine the strength of steel with the durability of reinforced concrete, offering an ideal solution for large-scale construction projects. These innovative beams are manufactured in our state-of-the-art facility, ensuring consistent quality and precise specifications. The prefabrication process significantly reduces on-site labor and construction time, making them perfect for projects with tight deadlines. Our SRC Composite Beams are designed to meet the most demanding structural requirements, providing exceptional load-bearing capacity and fire resistance.

Product Features:

- High load-bearing capacity

- Excellent fire resistance (up to 3 hours)

- Reduced on-site labor and construction time

- Customizable dimensions and specifications

- Superior durability and long-term performance

- Seamless integration with various building systems

Quality Control:

At Zhongda, we maintain rigorous quality control measures throughout the manufacturing process. Our Factory-Prefabricated SRC Composite Beams undergo extensive testing, including non-destructive evaluations and load-bearing simulations. We adhere to international standards and utilize advanced equipment to ensure each beam meets the highest quality benchmarks.

Why Choose Us?

- 60,000-ton annual production capacity

- ISO 9001/14001/45001 certified

- Class I Steel Structure Professional Contracting Qualification

- Cutting-edge CNC and automated welding technology

- Experienced team of engineers and technicians

- Proven track record with over 60 landmark projects

Production Process:

- Design and engineering

- Steel skeleton fabrication

- Reinforcement placement

- Concrete casting and curing

- Quality inspection and testing

OEM & ODM Services:

We offer comprehensive OEM and ODM services for the products, tailored to your specific project requirements. Our experienced team can work with you to develop custom solutions, including:

- Material Specifications: We use Q345B/C high-strength steel for the skeleton and C40-C60 concrete with compressive strength ≥50 MPa. Our beams are designed to withstand 8-degree seismic forces, with 20mm thick stiffening ribs welded at joint areas for enhanced stability.

- Customization Options: Choose from adjustable H-shaped or cross-shaped cross-sections with flange widths ranging from 200-800mm. We can also pre-install acoustic measuring tubes and other embedded components as needed.

- Anti-Corrosion Treatments: Our products feature hot-dip galvanizing with 275g/㎡ zinc coating and a 200μm thick epoxy coating for superior durability in harsh environments.

Project Cases:

Our products have been successfully implemented in numerous high-profile projects, including:

- Shenyang Dongta Cross-Hunhe River Bridge: 18,000-ton steel structure featuring our composite beams

- High-speed railway stations across China: Providing critical structural support

- Super high-rise buildings: Core tube structures utilizing our SRC Composite Beams

- Large-span industrial facilities: Enabling efficient and durable construction

Cases

Certifications:

- EN 1090-2 EXC3 Certification

- Third-Party Load Testing Reports available

Packaging and Delivery:

We ensure secure packaging and efficient logistics for all product orders. Standard specifications can be delivered within 30 days, while complex designs may require up to 45 days, including a 7-day curing period.

FAQ:

Q: What are the main advantages of the products?

A: Our beams offer superior strength, fire resistance, and reduced on-site construction time, making them ideal for large-scale projects with tight deadlines.

Q: Can you customize the beams for specific project requirements?

A: Absolutely! We offer extensive customization options, including dimensions, cross-sections, and embedded components to meet your unique needs.

Q: What is the typical delivery time for the products?

A: Standard specifications are typically delivered within 30 days, while complex designs may take up to 45 days, including the curing period.

Contact Us:

Ready to revolutionize your construction project with our Factory-Prefabricated SRC Composite Beams? Contact our expert team today at Ava@zd-steels.com for a personalized consultation and quote.

YOU MAY LIKE

Column_1745405748146.webp)