2. Seismic: Passed 8 - degree test, 20mm thick joint ribs.

3. Customization: Adjustable cross - section, pre - installed tubes.

4. Anti - corrosion: Hot - dip galvanizing (275g/㎡), epoxy coating (200μm).

5. Certifications: EN 1090 - 2 EXC3, third - party load report.

6. Delivery: Standard in 30 days (7 - day curing), complex in 45 days (7 - day curing).

7. Applications: High - speed railway stations, super high - rise cores, large - span facilities.

Long-Span Steel-Concrete Composite Beams: Revolutionizing Modern Construction

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of Long-Span Steel-Concrete Composite Beams. Our advanced technology, rigorous quality control, and innovative design set us apart in the industry. We offer superior load-bearing capacity, cost-effectiveness, and customization options that meet the diverse needs of large-scale construction projects.

Product Description:

Our products combine the strength of high-grade steel with the durability of reinforced concrete. These beams are engineered to span greater distances while maintaining structural integrity, making them ideal for commercial buildings, bridges, and industrial facilities. The steel skeleton, typically made from Q345B/C high-strength steel, works in perfect harmony with C40-C60 grade concrete (compressive strength ≥50 MPa) to create a robust, long-lasting structural element.

Product Features:

- Superior load-bearing capacity for extended spans

- Excellent fire resistance and sound insulation properties

- Reduced overall structural weight compared to traditional concrete beams

- Faster construction time due to prefabrication possibilities

- Versatile design options to suit various architectural requirements

Quality Control:

We implement stringent quality control measures throughout the production process. Our products undergo rigorous testing, including 8-degree seismic simulation tests. We also provide third-party load testing reports, ensuring that every beam meets or exceeds industry standards and your project specifications.

Why Choose Us?

- National High-Tech Enterprise with Class I Steel Structure Professional Contracting Qualification

- ISO 9001/14001/45001 certified manufacturing processes

- 60,000-ton annual production capacity with state-of-the-art equipment

- Collaborative R&D with top-tier design institutes and universities

- Proven track record with over 60 landmark projects completed

Production Process:

- Design and engineering

- Steel fabrication

- Concrete casting and curing

- Quality inspection and testing

- Surface treatment and finishing

OEM & ODM Services:

We offer comprehensive OEM and ODM services for Long-Span Steel-Concrete Composite Beams, tailoring our products to your specific project requirements. Our customization options include:

- Adjustable cross-sections (H-shaped or cross-shaped, flange width 200-800mm)

- Integration of pre-installed components like acoustic measuring tubes

- Specialized anti-corrosion treatments (hot-dip galvanizing with 275g/㎡ zinc coating or 200μm thick epoxy coating)

- Seismic reinforcement with 20mm thick stiffening ribs welded at joint areas

Our expert team works closely with you to develop optimal solutions that meet your design specifications, load requirements, and budgetary constraints.

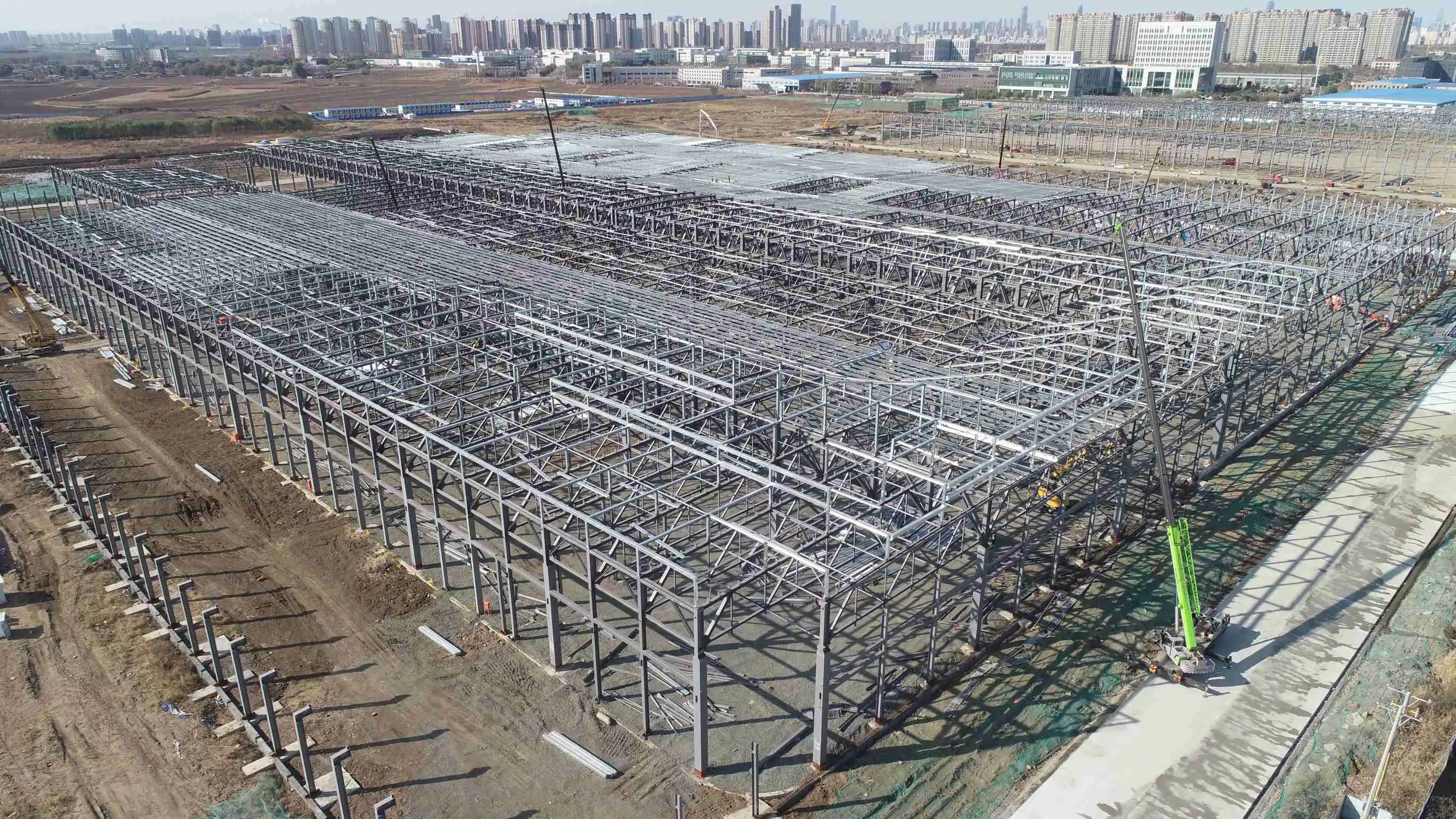

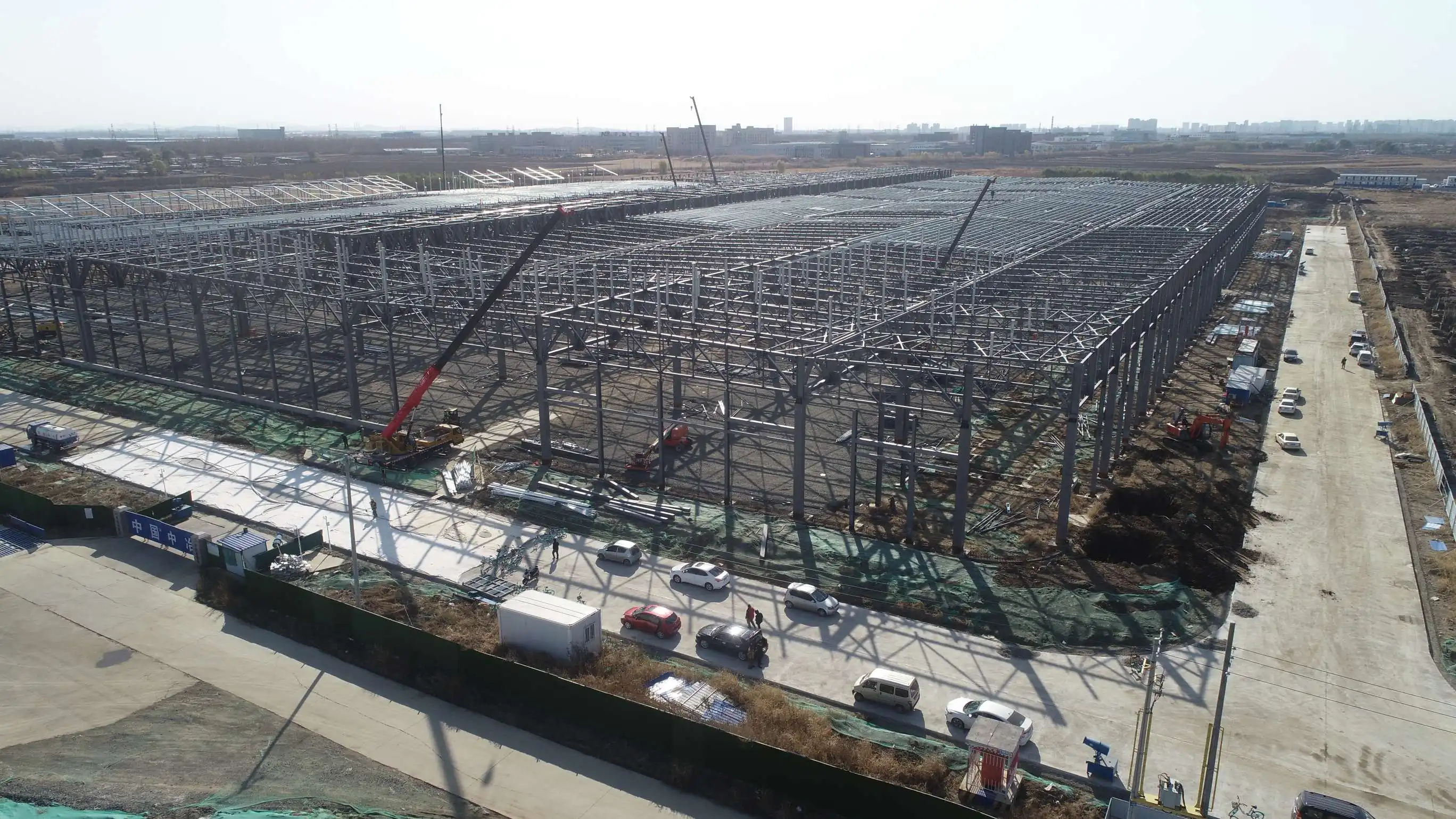

Project Cases:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- High-speed railway stations across China

- Core tubes for super high-rise buildings in major metropolitan areas

- Large-span industrial facilities for multinational corporations

Cases

Certifications:

- EN 1090-2 EXC3 Certification

- ISO 9001/14001/45001

- Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery:

At our company, we place great emphasis on the secure packaging and timely delivery of our products. Our dedicated packaging team uses high - quality materials, such as thick cardboard boxes and protective foams, to ensure that each item is well - safeguarded during transit. For standard specifications, we are committed to delivering within 30 days. However, for complex designs that require more intricate manufacturing processes, including a necessary 7 - day curing period for materials like concrete or certain adhesives, the delivery may take up to 45 days. This ensures that every product reaches our customers in perfect condition and within a reasonable time frame.

FAQ:

Q: What is the maximum span these beams can achieve?

A: Our products can span up to 30 meters, depending on the specific design and load requirements.

Q: Are these beams suitable for seismic zones?

A: Yes, our beams have passed 8-degree seismic simulation tests and can be reinforced for high seismic activity areas.

Q: Can you provide design assistance for our project?

A: Absolutely. Our engineering team offers comprehensive design support to optimize the use of our products in your project.

Contact Us:

Ready to revolutionize your construction project with our Long-Span Steel-Concrete Composite Beams? Contact us at Ava@zd-steels.com for a personalized consultation and quote.

YOU MAY LIKE

Column_1745405748146.webp)