2. Certifications: Malaysia CIDB, EN 10025 steel material report on request.

3. Customization: Adjustable steel skeleton cross - section, customizable concrete cover (50 - 150mm).

4. Delivery: Standard in 30 days (7 days curing), complex in 45 days (9 days curing).

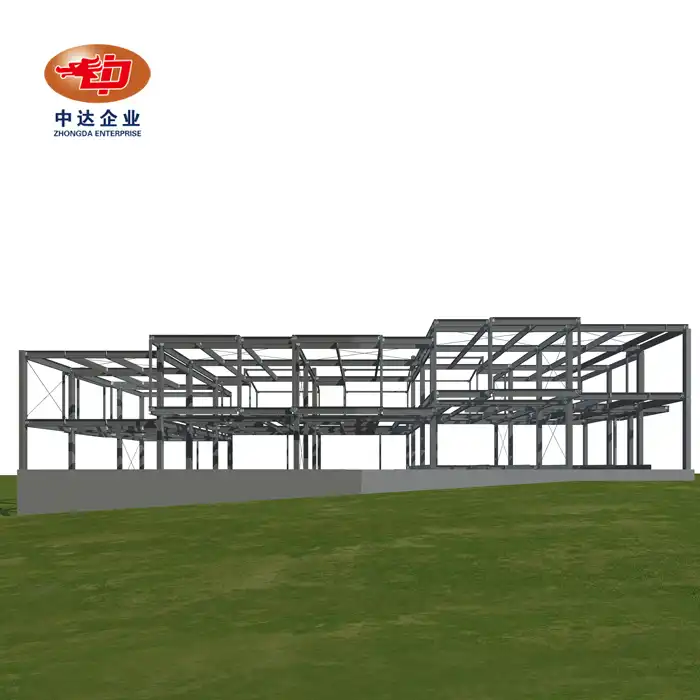

RC-SRC Composite Columns: Innovative Structural Solutions by Shenyang Zhongda

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of RC-SRC Composite Columns. Our advanced technology, rigorous quality control, and customization capabilities set us apart in the industry. Zhongda's products offer superior strength, durability, and cost-effectiveness for your large-scale construction projects.

Product Description: RC-SRC Composite Columns

Our products combine the best of reinforced concrete (RC) and steel-reinforced concrete (SRC) technologies. These innovative structural elements feature a high-strength steel core encased in high-performance concrete, providing exceptional load-bearing capacity and fire resistance. Ideal for high-rise buildings, bridges, and industrial facilities, our products offer:

- Enhanced structural integrity

- Improved seismic performance

- Reduced column cross-sections, maximizing usable floor space

- Lower overall construction costs

- Faster installation times compared to traditional columns

RC-SRC Composite Columns

.

Product Features of RC-SRC Composite Columns

- Core Steel Skeleton: High - strength Q345B/C steel forms the robust core. It offers excellent load - bearing capacity and resilience against various forces.

- Outer Structure: C40 - C60 concrete, with a compressive strength ≥50 MPa, provides enhanced protection and structural integrity to the outer shell.

- Adjustable steel skeleton cross - section (H - shaped or cross - shaped). Choose the ideal shape to optimize performance based on your project's specific load distribution needs.

- Customizable concrete cover thickness (50 - 150mm). Tailor the thickness to meet requirements for durability, insulation, and fire protection in different scenarios.

- Superior fire resistance and durability. The combination of materials ensures long - lasting performance, even in challenging environmental and fire - prone conditions.

Quality Control for RC-SRC Composite Columns

At Zhongda, we prioritize quality at every stage of production. Our RC-SRC Composite Columns undergo:

- Rigorous material testing and selection

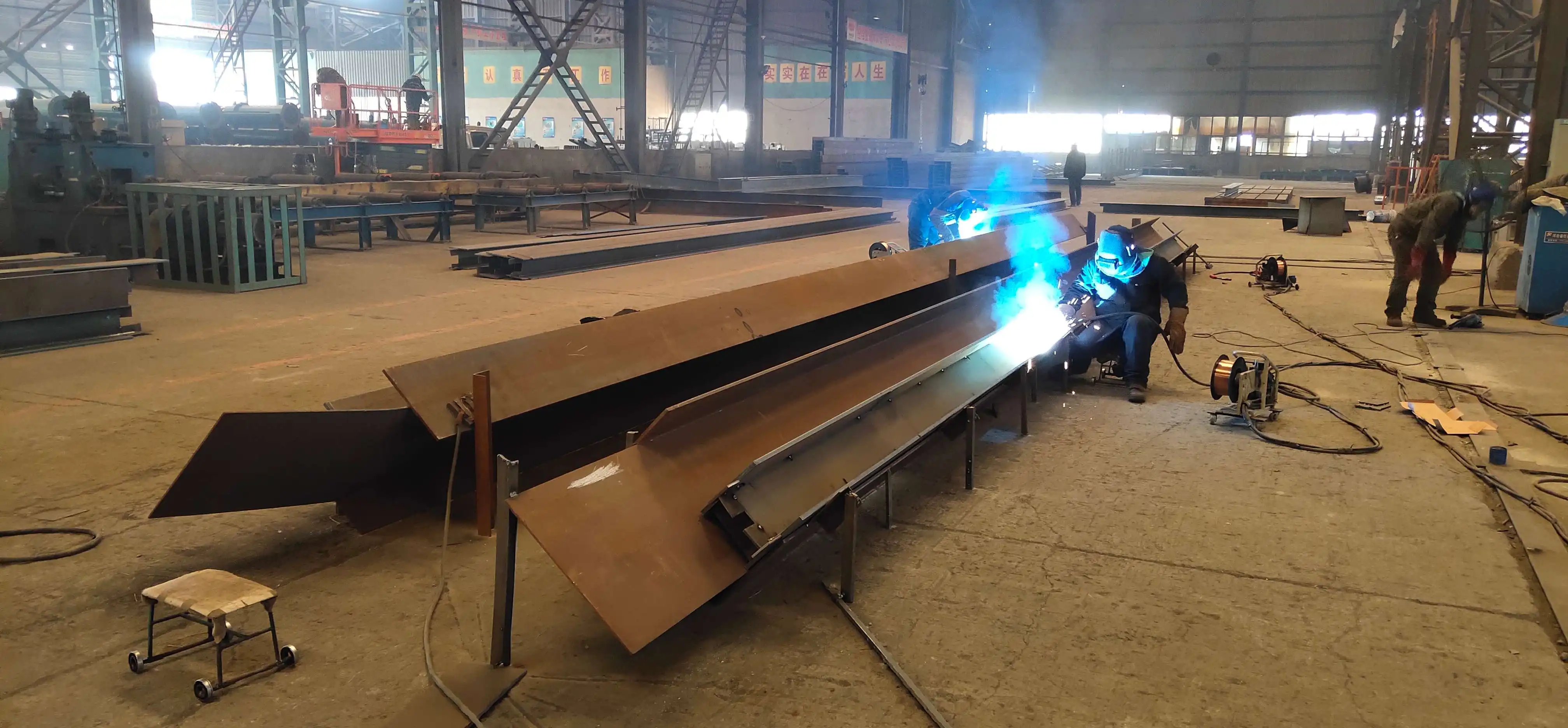

- Precision fabrication using advanced CNC equipment

- Non-destructive testing for structural integrity

- Strict adherence to international standards and local building codes

- Continuous quality monitoring throughout the manufacturing process

Why Choose Zhongda for RC-SRC Composite Columns?

- 60,000-ton annual production capacity

- Class I Steel Structure Professional Contracting Qualification

- ISO 9001/14001/45001 certifications

- Vertically integrated capabilities from R&D to construction

- Proven track record with over 60 landmark projects

- 70% client retention rate and 20-30% lead time reduction

Production Process for RC-SRC Composite Columns

- Steel core fabrication

- Reinforcement cage assembly

- Formwork preparation

- Concrete pouring and curing

- Quality inspection and finishing

OEM & ODM Services for RC-SRC Composite Columns

Zhongda offers comprehensive OEM and ODM services to meet your specific project requirements:

- Customizable material specifications

- Adjustable steel skeleton cross-sections

- Flexible concrete cover thickness options

- Compliance with international standards (EN 1090, AWS, JIS)

- Technical consultation and design optimization

- BIM-based digital design integration

Our experienced engineering team collaborates closely with clients to develop tailored product solutions that optimize performance, cost-efficiency, and constructability for your unique project needs.

Project Cases Featuring RC-SRC Composite Columns

- Shenyang Dongta Cross-Hunhe River Bridge (18,000-ton steel structure)

- Jingha Expressway expansion

- High-rise commercial buildings for leading property developers

- Industrial facilities for multinational corporations

- Overseas projects in Belt and Road countries

Certifications for RC-SRC Composite Columns

- Malaysia CIDB Certification (factory audit + laboratory testing)

- EN 10025 compliant steel material reports available

- ISO 9001, ISO 14001, ISO 45001 certifications

Packaging and Delivery of RC-SRC Composite Columns

- Secure packaging for safe transportation

- Standard specifications: 30-day delivery (including 7-day curing)

- Complex designs: 45-day delivery (including 7-day curing)

FAQ about RC-SRC Composite Columns

Q: How do products compare to traditional columns?

A: The products offer higher strength-to-size ratios, improved fire resistance, and better seismic performance while reducing overall project costs and construction time.

Q: Can you customize products for specific project requirements?

A: Yes, we offer full customization of steel skeleton cross-sections, concrete cover thickness, and material specifications to meet your unique project needs.

Q: What quality assurance measures do you have in place?

A: We employ rigorous quality control throughout the production process, including material testing, non-destructive evaluations, and adherence to international standards.

Contact Us for RC-SRC Composite Columns

Ready to elevate your construction project with our innovative RC-SRC Composite Columns? Contact our expert team at Ava@zd-steels.com for personalized solutions and competitive quotes.

YOU MAY LIKE