2. Intelligent: Laser cut ±0.5mm, flange 14 - 80mm.

3. Rapid: Bolted, 60% efficiency gain.

4. Anti - Corr: Double (spray + topcoat, GB/T 30790).

5. Certificates: ASTM A709 Gr.50W, fatigue test report.

6. Delivery: Standard 30 days, special 60 days.

7. Projects: Alaska, Nordic bridges.

Low-Temperature Resistant Hot-Rolled H-Section Plate Girders: Engineered for Extreme Conditions

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is your trusted manufacturer and supplier of Low-Temperature Resistant Hot-Rolled H-Section Plate Girders. Our advanced production capabilities, backed by ISO certifications and a Class I Steel Structure Professional Contracting Qualification, ensure top-quality products engineered to withstand the harshest environments.

Product Description

Our products are the cornerstone of resilient infrastructure in extreme climates. Crafted from Q420qE weather-resistant steel, these girders boast exceptional impact toughness, maintaining an impact energy of ≥34J at -40℃ (compliant with GB/T 714 standard). With customizable flange thicknesses ranging from 14-80mm and laser cutting precision of ±0.5mm, our plate girders offer unparalleled versatility for your most demanding projects.

Product Features

- Superior low-temperature performance

- Customizable dimensions to suit project requirements

- Bolted connection design for 60% faster on-site installation

- Optional double-layer protection: Arc-sprayed aluminum (150μm) + Fluorocarbon topcoat

- ASTM A709 Gr.50W Certification for assured quality

Quality Control

Our state - of - the - art facility stands as a testament to modern manufacturing excellence. Fitted with advanced CNC ultra - thick plate cutting technology capable of slicing through 300mm plates with remarkable precision, and complemented by highly efficient automated welding lines, we achieve unrivaled accuracy in production. Each product then embarks on a comprehensive quality control journey. It undergoes rigorous non - destructive testing to detect any hidden flaws, followed by third - party fatigue testing. This ensures that every item is primed for optimal performance in the most critical applications, providing our clients with utmost reliability.

Why Choose Us?

When you choose to collaborate with Zhongda, you're aligning with a preeminent figure in the low - temperature steel domain. Our substantial 60,000 - ton annual production capacity empowers us to meet large - scale demands efficiently. The impressive 70% client retention rate attests to our consistent delivery of top - notch products and services. Moreover, our proven track record of reducing lead times by 20 - 30% means your projects will progress on schedule, all while maintaining uncompromised quality standards.

Production Process

Our vertically integrated process is a comprehensive and efficient model that sets us apart. Starting from the initial phase of research and development, our in - house experts design innovative solutions. Precision fabrication follows, where state - of - the - art machinery crafts components with meticulous accuracy. Rigorous testing procedures are then carried out to guarantee the highest quality. Finally, construction is seamlessly managed. All these stages, from design inception to final delivery, occur within our facility, ensuring flawless quality control at every step of the project.

OEM & ODM Services

Leverage our expertise for your unique project needs. Our R&D collaboration with top-tier design institutes enables us to offer customized products tailored to your specifications. Whether you need special material compositions like BIMETAL Composite Plates or unique geometric configurations, our team is equipped to deliver. Our intelligent processing capabilities allow for rapid prototyping and efficient production scaling, ensuring your custom designs are realized with precision and timeliness.

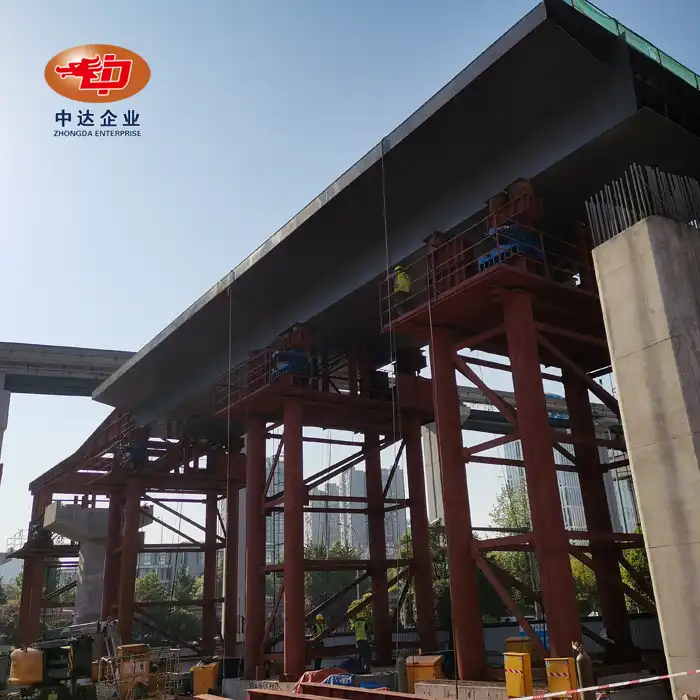

Project Cases

Our Low-Temperature Resistant Hot-Rolled H-Section Plate Girders have been integral to landmark projects worldwide:

- Alaska Polar Highway Bridge: Withstanding extreme arctic conditions

- Nordic Fjord Heavy-Load Bridges: Supporting vital transportation links in challenging environments

- Shenyang Dongta Cross-Hunhe River Bridge: Showcasing our 18,000-ton capacity in action

Certifications

ISO 9001/14001/45001 certified, with additional compliance to EN 1090, AWS, and JIS standards for global project integration.

Packaging and Delivery

Secure packaging ensures product integrity during transit. Standard specifications delivered within 30 days; special materials within 60 days.

FAQ

Q: What's the minimum order quantity for products?

A: We offer flexible MOQs to accommodate various project scales. Contact us for specific requirements.

Q: Can you provide custom dimensions for our project?

A: Absolutely! Our advanced manufacturing capabilities allow for customization to meet your exact specifications.

Contact Us

Ready to elevate your cold climate construction projects? Contact our expert team at Ava@zd-steels.com for personalized consultation and competitive quotations on Low-Temperature Resistant Hot-Rolled H-Section Plate Girders.

YOU MAY LIKE