2. Anti - Corr: Hot - Dip Galvanizing (ISO 1461), Dacromet (≥2000h).

3. Design: Span 30 - 100m, 5000kN capacity (mine bridges).

4. Construction: 85% pre - assembly, 7 - day on - site install.

5. Inspection: MT and RT reports.

6. Custom: Asymmetric trusses, detachable bridges etc.

7. Certification: EN1090 - 2 EXC4, BS5400 compliant.

Shenyang Zhongda Steel Structure Engineering Co., Ltd.: Your Premier Bolted Truss Bridge Manufacturer & Supplier

As a leading Bolted Truss Bridge manufacturer, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled expertise in design, fabrication, and installation. Our state-of-the-art facilities and comprehensive certifications ensure top-quality products that meet global standards and exceed client expectations.

Bolted Truss Bridge: Revolutionizing Infrastructure with Strength and Efficiency

Our products combine cutting-edge engineering with practical design, offering a robust solution for various infrastructure needs. These bridges feature high-strength steel components, precision-engineered connections, and modular construction for rapid deployment. Ideal for both permanent and temporary applications, our products are the go-to choice for government agencies and construction firms seeking reliability, cost-effectiveness, and swift project completion.

Key Features of Our Bolted Truss Bridges:

- Customizable spans from 30 to 100 meters

- High load capacity up to 5000kN

- Rapid on-site assembly (85% pre-assembled)

- Superior corrosion resistance with hot-dip galvanizing or Dacromet coating

- Compliance with international standards including EN1090-2 EXC4 and BS5400

Quality Control:

Our commitment to quality is evident in our rigorous testing procedures. Each Bolted Truss Bridge undergoes comprehensive non-destructive testing, including Magnetic Particle (MT) and Radiographic (RT) inspections. Our ISO 9001-certified quality management system ensures consistent, high-quality outputs that meet or exceed industry standards.

Why Choose Zhongda ?

With over 60 landmark projects completed, including the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, we bring unmatched experience to your project. Our 70% client retention rate and ability to reduce lead times by 20-30% demonstrate our commitment to excellence and efficiency in product construction.

Production Process: From Design to Delivery

Our production involves:

- BIM-based digital design

- Precision CNC fabrication

- Quality inspections

- Pre-assembly and testing

- Efficient packaging and shipping

OEM & ODM:

We offer comprehensive OEM and ODM services for the products, including:

- Customized designs for asymmetric trusses and emergency bridges

- High-strength connections using A490 (Grade 10.9) bolts with ±5% preload accuracy

- Advanced anti-corrosion treatments (hot-dip galvanizing or Dacromet coating)

- Modular designs for spans of 30-100 meters and loads up to 5000kN

- Rapid on-site installation, typically completed within 7 days

- Dual inspection reports (MT and RT) for quality assurance

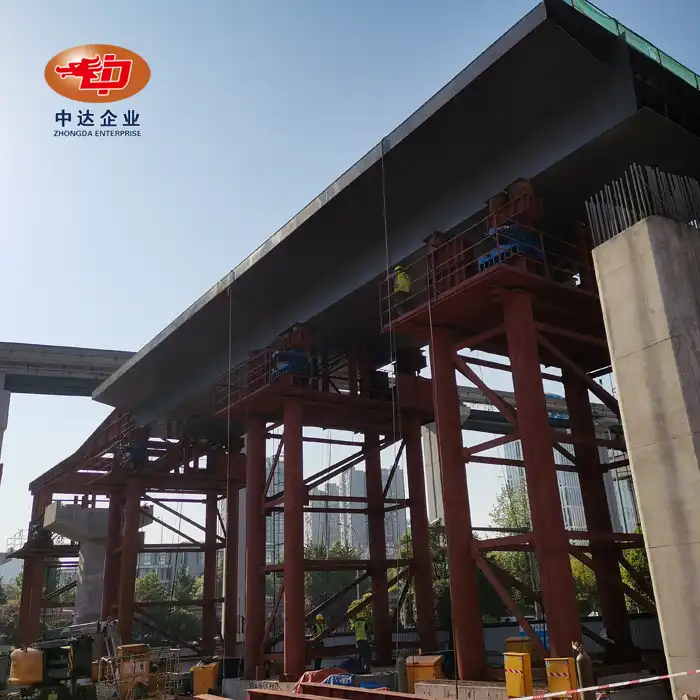

Project Showcase:

Our products have been successfully deployed in various challenging environments:

- Mining transport bridges in Australia, showcasing our international capabilities

- Jingha Expressway expansion, demonstrating our ability to handle large-scale infrastructure projects

- Emergency response bridges, highlighting our quick deployment solutions

These projects underscore our versatility and expertise in the product construction across diverse applications and geographies.

Certifications: Meeting Global Standards

Our products are backed by:

- ISO 9001/14001/45001 certifications

- EN 1090-2 EXC4 Certification

- Compliance with BS5400 Bridge Specifications

Packaging and Delivery: Ensuring Safe Transit

At our company, we recognize the critical importance of safeguarding product components throughout transit. That's why we implement highly specialized packaging techniques. Our team uses advanced materials and custom - designed packing solutions to shield delicate and crucial parts from potential damage during transportation. Paired with this, our extensive global logistics network is a well - oiled machine. Staffed by logistics experts, it efficiently coordinates shipments to project sites across the globe. This ensures that your products arrive on time, minimizing any delays and allowing you to optimize your construction timeline without a hitch.

FAQ

Q: What is the typical lifespan of a product?

A: With proper maintenance, our products can last 50-100 years.

Q: Can you provide on-site technical support during installation?

A: Yes, we offer comprehensive on-site support to ensure proper assembly and installation.

Q: Are your products suitable for seismic zones?

A: Absolutely. We can design products to meet specific seismic requirements.

Contact Us

Ready to elevate your infrastructure project with our Bolted Truss Bridge? Contact us at Ava@zd-steels.com for expert consultation and a tailored solution that meets your specific needs.

YOU MAY LIKE