2. Anti - Corr: Hot - Dip Galvanizing (ISO 1461), Dacromet (≥2000h).

3. Design: Span 30 - 100m, 5000kN capacity (mine bridges).

4. Construction: 85% pre - assembly, 7 - day on - site install.

5. Inspection: MT and RT reports.

6. Custom: Asymmetric trusses, detachable bridges etc.

7. Certification: EN1090 - 2 EXC4, BS5402 compliant.

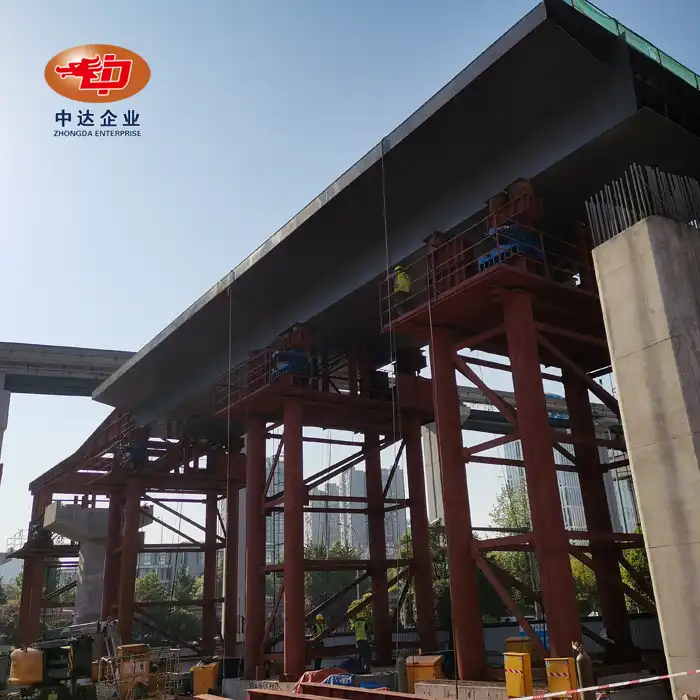

Galvanized Truss Bridge: Engineering Excellence by Shenyang Zhongda Steel

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading Galvanized Truss Bridge manufacturer and supplier. Our products stand out for their superior strength, durability, and cost-effectiveness, making us the preferred choice for infrastructure projects worldwide.

Product Description:

Our products are engineered to meet the most demanding infrastructure needs. Designed for longevity and performance, these bridges combine robust steel construction with hot-dip galvanization for unparalleled corrosion resistance. Ideal for road and railway crossings, pedestrian walkways, and industrial applications, our truss bridges offer exceptional load-bearing capacity and minimal maintenance requirements. With customizable spans ranging from 30 to 100 meters and load capacities up to 5000kN, our products are versatile solutions for various project requirements.

Features

- High-strength steel construction for maximum durability

- Hot-dip galvanization for superior corrosion protection

- Modular design for easy transportation and rapid installation

- Customizable spans and load capacities

- Low maintenance and long service life

- Compliance with international standards including EN1090-2 EXC4 and BS5400

Quality Control

At Shenyang Zhongda Steel, quality is paramount. Our Galvanized Truss Bridge undergo rigorous testing and inspection, including:

- Magnetic Particle Testing (MT) and Radiographic Testing (RT)

- Strict adherence to ISO 9001, ISO 14001, and ISO 45001 standards

- Full compliance with international bridge construction codes

- 100% quality inspection before shipment

Why Choose Us?

- We've built a proven track record by successfully completing over 60 landmark projects, showcasing our reliability and expertise in diverse endeavors.

- Our full - chain technical integration spans from initial design to final installation, ensuring seamless coordination and high - quality results throughout.

- Driven by R&D, we continuously introduce innovations and leverage proprietary technologies to stay ahead in the market and offer unique solutions.

- Our efficient processes have led to a 20 - 30% reduction in project lead times, enabling clients to complete projects faster and more cost - effectively.

- With deep expertise in global EPC project chains, we manage every aspect from procurement to construction, ensuring smooth project execution worldwide.

Galvanized Truss Bridge Production Process

- Design and engineering

- Precision fabrication

- Hot-dip galvanization

- Quality inspection

- Pre-assembly and testing

- Packaging and shipping

OEM & ODM Services

We offer comprehensive OEM and ODM services for the products, tailored to your specific project needs:

- High-Strength Connections: Using A490 (Grade 10.9) bolts with preload accuracy within ±5% error.

- Enhanced Anti-Corrosion: Choose between hot-dip galvanizing (ISO 1461 compliant) or Dacromet coating (2000+ hours salt spray resistance).

- Customized Modular Design: Single spans from 30-100 meters, with load capacities up to 5000kN for specialized applications like mine transport bridges.

- Rapid Deployment: 85% factory pre-assembly rate, enabling on-site installation in just 7 days.

- Advanced Inspection: Dual reports including Magnetic Particle Testing (MT) and Radiographic Testing (RT).

- Bespoke Solutions: We support asymmetric trusses, detachable emergency bridges, and other custom requirements.

Project Cases

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion project

- Multiple railway and highway bridges for China Railway and CCCC

- Industrial plant access bridges for mining operations in Australia

- Emergency response bridges for military applications

Certifications

- ISO 9001, ISO 14001, ISO 45001

- EN1090-2 EXC4 Certification

- Class I Steel Structure Professional Contracting Qualification

Packaging and Delivery

- Secure packaging for long-distance transportation

- Global shipping capabilities with door-to-door service

- Modular design for easy container loading and unloading

FAQ

Q: What is the typical lifespan of your products?

A: With proper maintenance, our bridges can last 50-100 years, depending on environmental conditions.

Q: Can you provide on-site installation support?

A: Yes, we offer comprehensive installation services and technical support worldwide.

Q: How do you ensure the quality of your products?

A: We employ strict quality control measures, including non-destructive testing and adherence to international standards throughout the production process.

Contact Us for Galvanized Truss Bridge Solutions

Ready to start your Galvanized Truss Bridge project? Contact our expert team at Ava@zd-steels.com for personalized assistance and quotations.

YOU MAY LIKE