2. Intelligent: Laser cut ±0.5mm, flange 14 - 80mm.

3. Rapid: Bolted, 60% efficiency gain.

4. Anti - Corr: Double (spray + topcoat, GB/T 30790).

5. Certificates: ASTM A709 Gr.50W, fatigue test report.

6. Delivery: Standard 30 days, special 60 days.

7. Projects: Alaska, Nordic bridges.

Q345D Hot-Rolled Steel Plate Girder: Premium Quality for Your Heavy-Duty Projects

At Shenyang Zhongda Steel Structure Engineering Co., Ltd., we're your trusted manufacturer and supplier of top-tier Q345D Hot-Rolled Steel Plate Girders. Our advanced production capabilities, stringent quality control, and commitment to innovation make us the go-to choice for construction and infrastructure projects demanding superior strength and durability.

Product Description:

Our products are engineered to meet the most demanding requirements of large-scale construction and infrastructure projects. These high-performance girders offer exceptional strength-to-weight ratios, making them ideal for bridges, high-rise buildings, and heavy industrial structures. With a yield strength of 345 MPa and excellent low-temperature toughness, our Q345D girders ensure reliability in even the most challenging environments.

Key features of our products include:

- Superior strength and durability for long-lasting performance

- Excellent weldability for ease of fabrication and assembly

- High resistance to atmospheric corrosion

- Consistent quality across large-scale production runs

- Customizable dimensions to suit your specific project needs

Quality Control:

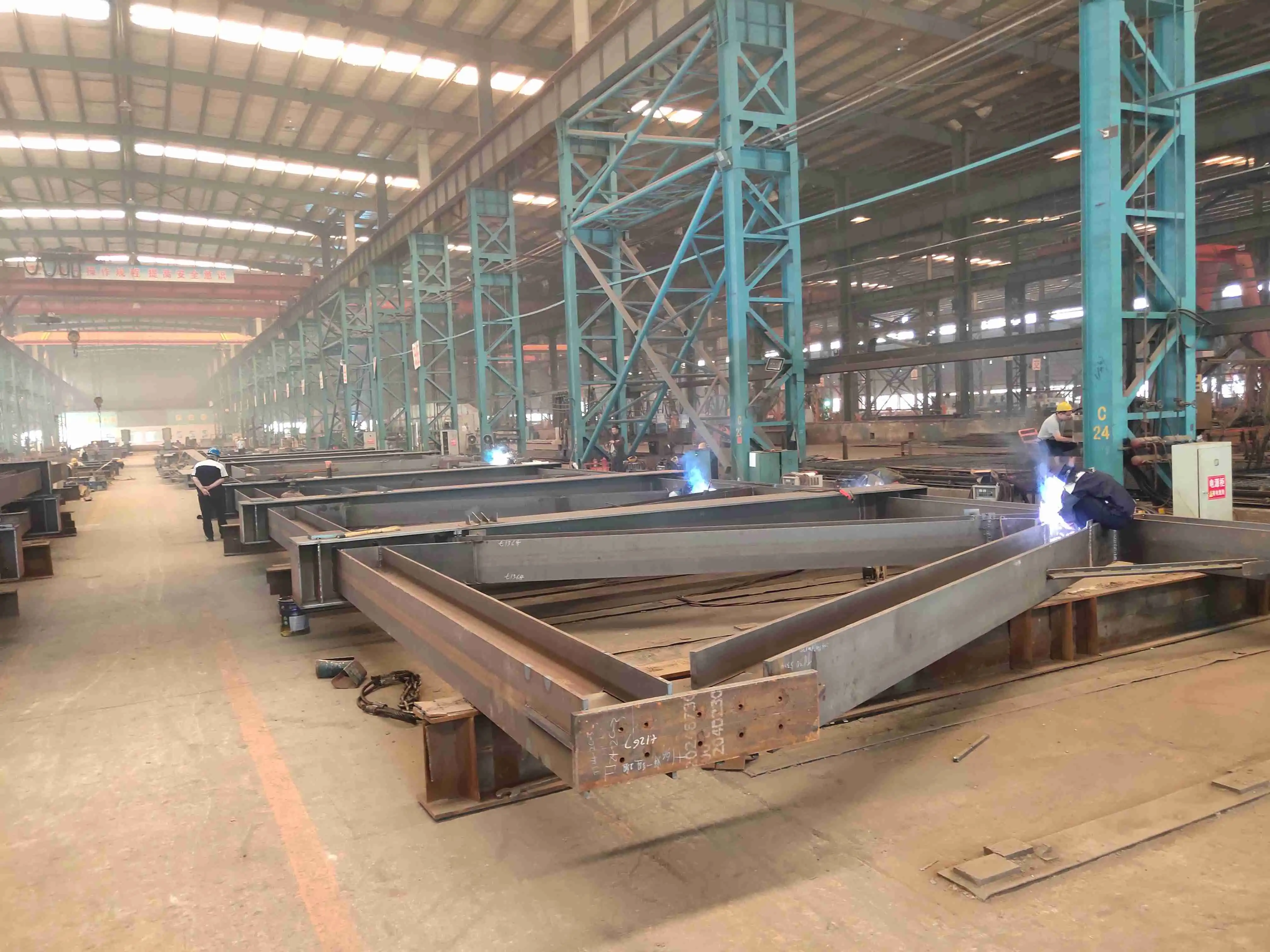

We implement rigorous quality control measures throughout our production process. Our state-of-the-art testing facilities ensure that every Q345D Hot-Rolled Steel Plate Girders meets or exceeds industry standards. We conduct regular chemical composition analyses, mechanical property tests, and non-destructive evaluations to guarantee the highest quality product for our clients.

Why Choose Us?

Shenyang Zhongda Steel Structure Engineering Co., Ltd. stands out as your premier partner for products. Our vertically integrated capabilities, from R&D to precision fabrication and construction, ensure seamless project execution. With our 60,000-ton annual production capacity and advanced equipment, we deliver high-precision, high-efficiency solutions that save you time and resources.

Production Process:

Our products are manufactured using cutting-edge technology, including CNC ultra-thick plate cutting (up to 300mm) and automated welding lines, ensuring consistent quality and precise specifications.

OEM & ODM Services:

We offer comprehensive OEM and ODM services tailored to your unique project requirements. Our team of experienced engineers collaborates closely with you to develop custom product solutions that optimize performance and cost-effectiveness. Whether you need specialized dimensions, enhanced corrosion resistance, or specific load-bearing capacities, we have the expertise to deliver.

Our OEM and ODM capabilities include:

- Custom design and engineering services

- Material selection and optimization

- Prototyping and testing

- Large-scale production with stringent quality control

- Specialized surface treatments and coatings

- Comprehensive documentation and certifications

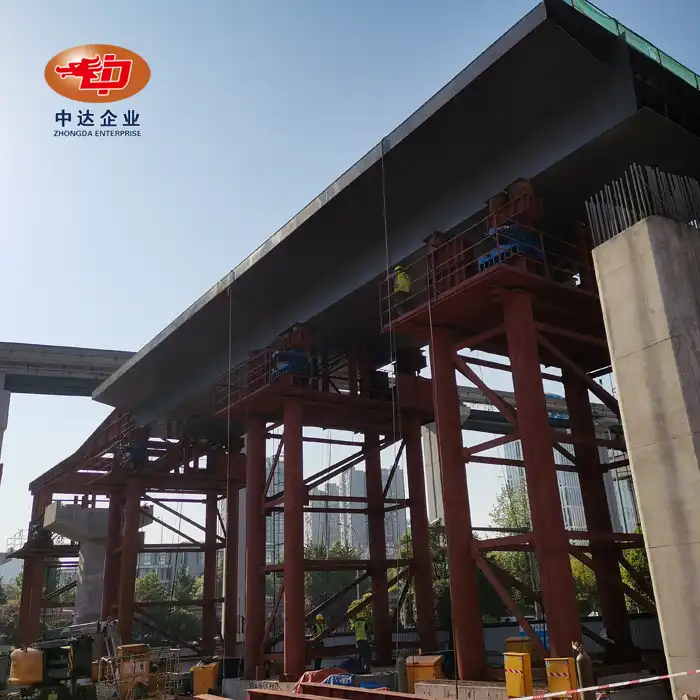

Project Cases:

Our products have been successfully utilized in numerous high-profile projects, including:

- The 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge, showcasing our ability to deliver on large-scale infrastructure projects.

- Multiple industrial plant constructions for leading companies in the manufacturing sector, demonstrating our versatility and reliability.

- Overseas projects, including Australian mining crushing stations, highlighting our global reach and compliance with international standards.

Certifications:

Our products are manufactured in compliance with ISO 9001, ISO 14001, and ISO 45001 standards, ensuring top-quality products that meet global requirements.

Packaging and Delivery:

At our company, we prioritize the safety of your products throughout their journey. We employ secure packaging techniques, using high - quality materials and advanced cushioning methods. This ensures that your items are well - protected from potential damage during transportation, whether by land, sea, or air. Our efficient logistics network is staffed by experienced professionals who plan and execute deliveries with precision. No matter where your project site is located around the globe, we guarantee timely arrival, keeping your project on track without any delays.

FAQ:

Q: What is the typical lead time for the products?

A: For standard specifications, we offer a 30-day lead time. For custom orders or special materials, lead times may extend to 60 days.

Q: Can you provide custom dimensions for the products?

A: Absolutely. We specialize in customizing girders to meet your specific project requirements, with flange thicknesses ranging from 14mm to 80mm.

Contact Us:

Ready to elevate your construction project with our premium Q345D Hot-Rolled Steel Plate Girders? Contact our expert team at Ava@zd-steels.com for personalized assistance and competitive quotes. Let's build something extraordinary together!

YOU MAY LIKE