2. Material: Q345D main (≥345MPa), Q420D for joints.

3. Customization: Variable cross - section (1.25 - 8m), 20% weight reduction, 420m span.

4. Construction: Prefabrication (12 - 30m), on - site assembly, 50% time reduction.

5. Anti - Corrosion: Double (galvanizing or spraying), ≥30 years service.

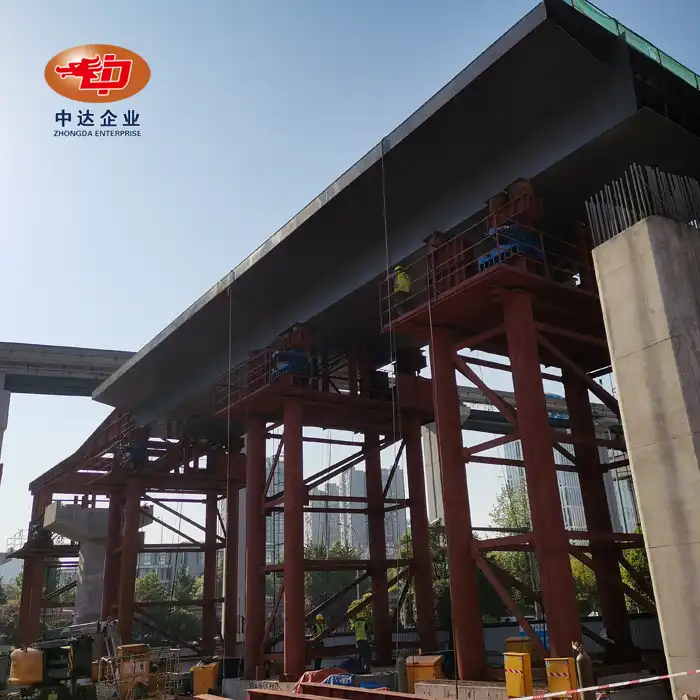

Steel Box Girder: Shenyang Zhongda's High-Performance Solution for Major Infrastructure Projects

Shenyang Zhongda Steel Structure Engineering Co., Ltd. is a leading manufacturer and supplier of premium Steel Box Girders. Our advanced manufacturing capabilities, coupled with our commitment to quality and innovation, make us the preferred choice for large-scale infrastructure projects worldwide.

Product Description:

Our products are the backbone of modern bridge construction, offering unparalleled strength and durability for long-span structures. Designed to meet the most demanding engineering specifications, these girders provide superior load-bearing capacity and resistance to torsional forces. Whether you're planning a major river crossing or expanding a highway system, our products deliver the performance and reliability you need for success.

Key features of our Steel Box Girders include:

- Fully welded box section design for optimal strength distribution

- Customizable dimensions to suit project-specific requirements

- High-strength Q345D and Q420D steel for critical components

- Corrugated steel web option for weight reduction

- Factory prefabrication for rapid on-site assembly

- Advanced anti-corrosion treatments for extended service life

Quality Control:

At Shenyang Zhongda, quality is paramount. Our products undergo rigorous testing and inspection at every stage of production. Our state-of-the-art facilities, including CNC ultra-thick plate cutting and automated welding lines, ensure precision manufacturing. We adhere to international standards such as ISO 9001, EN 1090, and AWS, guaranteeing consistent quality that meets global requirements.

Why Choose Us?

- Vertically integrated capabilities from R&D to construction

- 60,000-ton annual production capacity

- Expertise in complex, large-scale projects

- 70% client retention rate

- 20-30% reduction in project lead times

- Compliance with international standards for global project integration

Production Process:

Our streamlined production process includes design optimization, precision cutting, automated welding, quality inspection, and corrosion protection application, ensuring efficient delivery of high-quality Steel Box Girders.

OEM & ODM Services:

We offer comprehensive customization options to meet your specific project needs:

- Variable cross-section design with beam heights from 1.25m to 8m

- Corrugated steel web optimization for up to 20% weight reduction

- Maximum single span capability of 420 meters

- Tailored anti-corrosion solutions for harsh environments

- BIM-based design integration for seamless project coordination

- Technical support throughout the project lifecycle

Our engineering team collaborates closely with clients to develop bespoke solutions that optimize performance, reduce costs, and accelerate construction timelines.

Project Cases:

Our products have been instrumental in numerous landmark projects, including:

- 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge

- Jingha Expressway expansion

- Multiple long-span railway bridges across China

- International projects in collaboration with global EPC firms

These successful implementations showcase our ability to deliver high-quality products for diverse and challenging infrastructure projects.

Certifications:

ISO 9001/14001/45001, Class I Steel Structure Professional Contracting Qualification, EN 1090, AWS, JIS

Packaging and Delivery:

We understand that each project comes with its own unique set of requirements. That's why we go the extra mile to provide secure packaging, using top - notch materials to safeguard products from any potential damage during transit. In addition, we offer flexible delivery options. Whether your project schedule is tight or your site has specific access conditions, we can adapt. Our team carefully assesses your needs and devises a delivery plan that ensures the safe and timely arrival of the products, so you can focus on your project without worry.

FAQ:

Q: What is the typical lead time for the product orders?

A: Lead times vary based on project specifications and quantity. We generally aim for a 20-30% reduction in lead times compared to industry standards.

Q: Can you provide technical assistance during installation?

A: Yes, our experienced engineers offer comprehensive support throughout the project, including on-site guidance during installation.

Q: How do you ensure consistent quality across large orders?

A: Our vertically integrated production process and stringent quality control measures, backed by international certifications, guarantee consistent high quality for every product we produce.

Contact Us:

Ready to elevate your infrastructure project with our high-performance Steel Box Girders? Contact us at Ava@zd-steels.com for expert consultation and competitive quotes tailored to your specific requirements.

YOU MAY LIKE