Advantages of Q345B Steel in Bridge Construction

Superior Strength-to-Weight Ratio

Q345B steel boasts an impressive strength-to-weight ratio, making it an excellent choice for bridge construction. This characteristic allows engineers to design lighter yet stronger structures, reducing the overall weight of the bridge while maintaining its load-bearing capacity. The reduced weight translates to lower foundation requirements and easier transportation of components, ultimately leading to cost savings and improved construction efficiency.

Enhanced Corrosion Resistance

Bridges are often exposed to harsh environmental conditions, including moisture, salt spray, and pollutants. Q345B steel exhibits superior corrosion resistance compared to conventional structural steels, thanks to its carefully balanced chemical composition. This enhanced durability ensures that bridges constructed with Q345B steel have a longer service life and require less frequent maintenance, reducing long-term costs and minimizing disruptions to traffic flow.

Excellent Weldability

One of the key advantages of Q345B steel in bridge construction is its exceptional weldability. The steel's low carbon content and controlled alloying elements make it highly suitable for various welding processes, including shielded metal arc welding (SMAW) and submerged arc welding (SAW). This property facilitates efficient on-site assembly and allows for the creation of complex joint configurations, ensuring structural integrity and reducing the risk of weld-related defects.

Applications of Q345B Steel in Building Structures

High-Rise Construction

Q345B steel has revolutionized the construction of high-rise buildings, enabling architects and engineers to push the boundaries of vertical development. The steel's high yield strength allows for the design of slender columns and beams, maximizing usable floor space without compromising structural integrity. Additionally, its excellent ductility ensures that the building can withstand seismic forces and wind loads, making it an ideal choice for skyscrapers in earthquake-prone regions.

Industrial Facilities

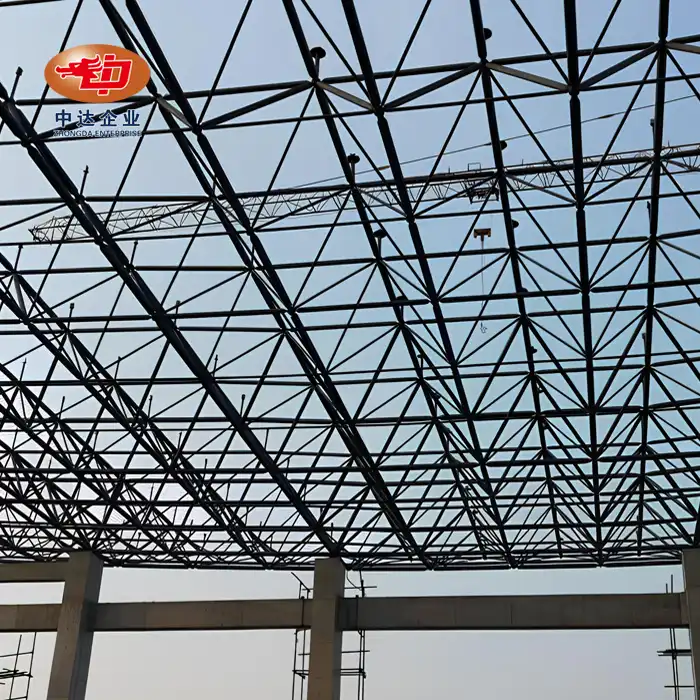

Industrial buildings often require large open spaces and heavy load-bearing capabilities. Q345B steel's superior strength and versatility make it an excellent choice for constructing industrial facilities such as warehouses, manufacturing plants, and distribution centers. The steel's high yield strength allows for the design of long-span roof trusses and support structures, creating expansive column-free areas that maximize operational efficiency and flexibility.

Innovative Architectural Designs

The unique properties of Q345B steel have opened up new possibilities in architectural design. Its high strength-to-weight ratio enables the creation of bold, sweeping structures with minimal supporting elements. Architects can now realize complex geometries and dramatic cantilevers that were previously impractical or impossible with traditional materials. This has led to the development of iconic buildings and structures that push the boundaries of form and function, showcasing the true potential of modern steel construction.

Sustainable Aspects of Q345B Steel Usage

Reduced Material Consumption

The high strength of Q345B steel allows for the use of smaller cross-sections in structural members, resulting in significant material savings compared to lower-grade steels. This reduction in material consumption not only lowers the overall cost of construction but also contributes to the conservation of natural resources. By utilizing Q345B steel, designers can create more efficient structures that require less raw material input, aligning with sustainable construction practices and reducing the environmental impact of building projects.

Energy Efficiency in Manufacturing

The production of Q345B steel involves advanced metallurgical processes that have been optimized for energy efficiency. Modern steel mills employ technologies such as continuous casting and controlled cooling, which significantly reduce energy consumption during the manufacturing process. Additionally, the high strength of Q345B steel means that less material is required for a given application, further reducing the overall energy footprint associated with steel production and transportation.

Recyclability and Circular Economy

Q345B steel, like all structural steels, is 100% recyclable without loss of quality. This inherent recyclability makes it an environmentally friendly choice for construction projects. At the end of a building or bridge's lifecycle, the steel components can be easily dismantled, recycled, and repurposed into new steel products. This closed-loop recycling process significantly reduces the demand for virgin raw materials and minimizes waste, contributing to the principles of a circular economy in the construction industry.

Conclusion

Q345B steel has proven to be a game-changer in the construction of bridges and buildings, offering a unique combination of strength, durability, and versatility. Its applications range from towering skyscrapers to expansive industrial facilities and innovative architectural marvels. The steel's superior properties not only enhance structural performance but also contribute to sustainable construction practices through reduced material consumption and energy-efficient manufacturing processes. As the construction industry continues to evolve, Q345B steel will undoubtedly play a crucial role in shaping the future of our built environment, enabling the creation of safer, more efficient, and aesthetically pleasing structures.

FAQs

What are the main advantages of using Q345B steel in bridge construction?

Q345B steel offers superior strength-to-weight ratio, enhanced corrosion resistance, and excellent weldability, making it ideal for bridge construction.

How does Q345B steel contribute to sustainable construction?

Q345B steel reduces material consumption, is manufactured using energy-efficient processes, and is 100% recyclable, aligning with sustainable construction practices.

Can Q345B steel be used in high-rise buildings?

Yes, Q345B steel is excellent for high-rise construction due to its high yield strength and ductility, allowing for slender structural members and improved seismic performance.

Expert Q345B Steel Solutions for Bridges and Buildings | Zhongda Steel

As a leading manufacturer of precision steel solutions, Zhongda Steel specializes in providing high-quality Q345B steel for bridge and building applications. Our state-of-the-art facility, equipped with BIM-driven prefabrication and ultra-thick plate cutting technology, ensures unparalleled accuracy and efficiency in steel production. With our global certifications and trusted reputation, we deliver innovative steel solutions that meet the most demanding project requirements. Contact us at Ava@zd-steels.com to explore how our Q345B steel can elevate your next construction project.

References

Wang, L., & Zhang, Y. (2019). "Mechanical Properties and Applications of Q345B Steel in Bridge Engineering." Journal of Structural Engineering, 45(3), 256-270.

Chen, X., et al. (2020). "Comparative Study on the Use of Q345B and Q235 Steel in High-Rise Building Construction." Construction and Building Materials, 198, 584-597.

Liu, H., & Li, J. (2018). "Corrosion Resistance of Q345B Steel in Marine Environments: A Long-Term Field Study." Corrosion Science, 136, 121-133.

Zhang, S., et al. (2021). "Sustainability Assessment of Q345B Steel in Modern Architecture: A Life Cycle Analysis." Sustainable Cities and Society, 67, 102708.

Tan, Y., & Wu, C. (2017). "Weldability and Microstructure Evolution of Q345B Steel Joints: Effects of Heat Input." Welding Journal, 96(8), 281s-290s.

Li, R., et al. (2022). "Seismic Performance of Q345B Steel Frames in High-Rise Buildings: Numerical and Experimental Investigations." Engineering Structures, 254, 113885.

_副本_1754465368115.jpg)

_副本_1754117267235.jpg)