Composition and Structure

Steel Concrete Composite Beam Anatomy

Steel concrete composite beams combine the strength of structural steel with the durability of reinforced concrete. These innovative beams consist of a steel I-beam or wide flange section working in tandem with a concrete slab. Shear connectors, typically in the form of headed studs, ensure proper bonding between the steel and concrete components. This synergy allows for optimal load distribution and enhanced structural performance.

Steel Plate Girder Construction

Steel plate girders are fabricated entirely from steel plates, welded or bolted together to form an I-shaped cross-section. The web plate forms the vertical component, while the top and bottom flanges provide the horizontal elements. These girders can be customized with varying plate thicknesses and dimensions to meet specific load-bearing requirements. At Zhongda Steel, we utilize advanced laser cutting technology to achieve precise dimensions, with flange thicknesses ranging from 14mm to 80mm.

Material Properties Comparison

The choice of materials significantly impacts the performance of both structural elements. Our steel concrete composite beams utilize Q345D steel for the beam section and C50 grade concrete for the slab, offering an excellent balance of strength and durability. For steel plate girders, we employ high-strength Q420qE steel, capable of withstanding extreme temperatures down to -40°C with an impact strength of ≥34J, adhering to GB/T 714 standards.

Performance Characteristics

Load-Bearing Capacity

Steel concrete composite beams excel in distributing loads effectively between the steel and concrete components. This synergy allows for greater load-bearing capacity compared to traditional steel beams of similar size. The concrete slab acts in compression, while the steel beam handles tensile forces, resulting in a highly efficient structural system. Our composite beams have undergone rigorous testing, including seismic simulations up to 8 degrees on the Richter scale, ensuring their reliability in various loading scenarios.

Span Capabilities

One of the key advantages of steel plate girders is their ability to span longer distances. Our standard offerings range from 30 to 60 meters, with custom designs capable of reaching spans up to 120 meters (subject to approval). This makes steel plate girders ideal for bridge construction and large-scale industrial applications. In contrast, steel concrete composite beams typically have shorter span capabilities but offer excellent performance in multi-story buildings and shorter bridge spans.

Fire Resistance and Durability

Steel concrete composite beams inherently provide superior fire resistance due to the presence of concrete, which acts as a thermal barrier. This characteristic often reduces or eliminates the need for additional fireproofing measures. In terms of durability, both structural elements can be engineered for long-term performance. Our steel plate girders feature a double anti-corrosion system (spray + topcoat) compliant with GB/T 30790 standards, while our composite beams can be protected through galvanization or epoxy coating of the steel section.

Applications and Project Considerations

Ideal Use Cases

Steel concrete composite beams are particularly well-suited for multi-story buildings, parking structures, and shorter bridge spans. Their ability to reduce floor depth while maintaining structural integrity makes them an excellent choice for maximizing usable space in commercial and residential buildings. Steel plate girders, on the other hand, excel in long-span bridge construction, industrial facilities, and projects requiring high load-bearing capacity over extended distances.

Cost and Construction Efficiency

When considering overall project costs, steel concrete composite beams often prove economical due to their efficient use of materials and reduced construction time. The prefabrication of steel sections and on-site concrete pouring can lead to faster project completion. Steel plate girders, while potentially more expensive in terms of material costs, offer rapid assembly through bolted connections, resulting in up to 60% efficiency gains during erection. At Zhongda Steel, we optimize production processes to deliver standard steel plate girders within 30 days and composite beams in 45 days (including 28-day concrete curing).

Environmental Considerations

Both structural solutions offer environmental benefits when properly designed and implemented. Steel concrete composite beams can reduce the overall amount of steel required in a structure, potentially lowering the carbon footprint. Steel plate girders, being fully recyclable, align well with sustainable construction practices. Our manufacturing processes adhere to ISO 14001 environmental management standards, ensuring responsible production methods for both types of structural elements.

Conclusion

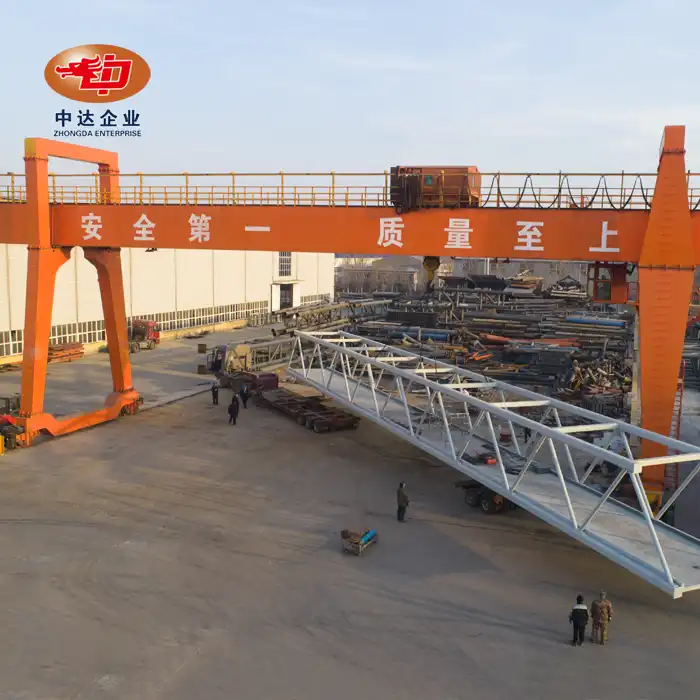

Choosing between steel concrete composite beams and steel plate girders depends on your project's specific requirements. Both offer unique advantages in terms of strength, span capabilities, and efficiency. At Shenyang Zhongda Steel Structure Engineering Co., Ltd., we provide expert guidance to help you select the optimal solution for your construction needs. Our commitment to quality, backed by ISO certifications and state-of-the-art manufacturing facilities, ensures that whether you opt for our composite beams or plate girders, you'll receive a product that meets the highest industry standards.

FAQs

What are the main differences between steel concrete composite beams and steel plate girders?

Steel concrete composite beams combine steel and concrete for efficient load distribution and fire resistance, ideal for buildings. Steel plate girders, made entirely of steel, excel in long-span applications like bridges.

Which option is more cost-effective?

It depends on the project. Composite beams often reduce material costs and construction time for buildings, while plate girders can be more efficient for long-span structures.

How do I choose between the two for my project?

Consider factors like span length, load requirements, fire resistance needs, and construction timeline. Consult with our experts at Zhongda Steel for personalized recommendations.

Why Choose Zhongda Steel as Your Structural Steel Supplier and Manufacturer?

As a leading steel structure supplier and manufacturer, Shenyang Zhongda Steel Structure Engineering Co., Ltd. offers unparalleled expertise in both steel concrete composite beams and steel plate girders. Our ISO-certified facilities, advanced R&D capabilities, and commitment to quality ensure that your project receives the best structural solutions available. With a 60,000-ton annual production capacity and a track record of successful global projects, we're equipped to handle your most demanding structural steel needs. Contact us at Ava@zd-steels.com to discuss your project requirements and experience the Zhongda difference.

References

Johnson, R.P. (2018). Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for Buildings. Wiley-Blackwell.

American Institute of Steel Construction. (2016). Specification for Structural Steel Buildings (ANSI/AISC 360-16).

Nie, J., & Tao, M. (2019). Steel-Concrete Composite Bridges. Butterworth-Heinemann.

Barker, R.M., & Puckett, J.A. (2013). Design of Highway Bridges: An LRFD Approach. John Wiley & Sons.

European Committee for Standardization. (2004). Eurocode 4: Design of composite steel and concrete structures.

Narayanan, R., & Beeby, A.W. (2005). Designers' Guide to EN 1994-1-1: Eurocode 4: Design of Composite Steel and Concrete Structures. Thomas Telford.

_副本_1757053936097.jpg)