Key Factors in Choosing Platform Beam Materials

Strength and Load-Bearing Capacity

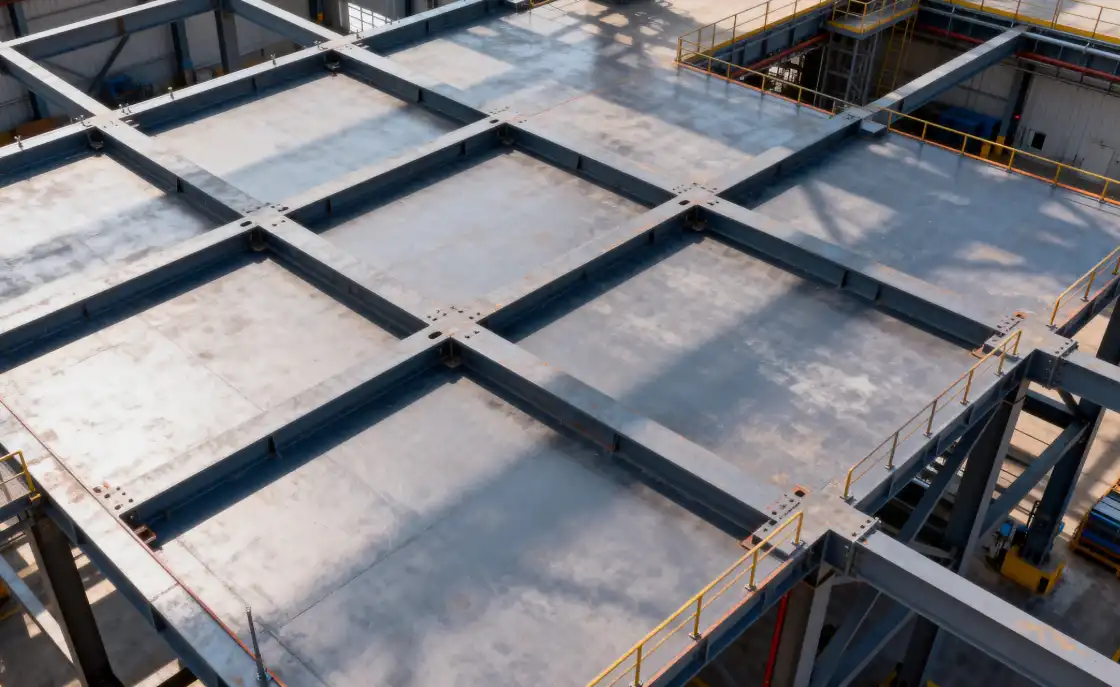

The primary consideration when selecting materials for platform beams is their strength and load-bearing capacity. Hot-rolled Q345B H-shaped steel excels in this aspect, offering superior structural integrity and the ability to support heavy loads. This high-performance steel grade provides a yield strength of 345 MPa, making it ideal for industrial applications where robust support is essential.

Platform beams made from Q345B steel can easily handle uniform loads of 5 kN/m² or more, depending on the specific design requirements. This exceptional strength allows for the creation of spacious, multi-level mezzanines and equipment platforms without compromising on safety or stability. The material's inherent properties also contribute to its resistance to deformation under stress, ensuring long-term reliability in various operational environments.

Durability and Corrosion Resistance

Longevity is a critical factor in platform beam construction, and the choice of material plays a significant role in determining the structure's lifespan. Q345B steel, when properly treated, offers excellent durability and corrosion resistance. At Shenyang Zhongda Steel, we enhance the natural properties of this steel through hot-dip galvanization, applying a zinc layer of 120μm or more to protect against corrosion.

This galvanization process creates a sacrificial layer that shields the underlying steel from environmental factors, significantly extending the platform's service life. For environments with particularly harsh conditions, we also offer fluorocarbon coating as an alternative protective measure. These treatments ensure that platform beams can withstand various weather conditions and resist corrosion for up to 30 years, making them a cost-effective long-term solution for industrial and commercial applications.

Flexibility and Customization

The adaptability of platform beam materials to various design requirements is crucial for meeting diverse project needs. Q345B H-shaped steel offers exceptional flexibility in this regard. Its properties allow for customizable column sections ranging from 200×200mm to 400×400mm, accommodating different load requirements and spatial constraints.

Furthermore, the material's workability enables the creation of bolted connections, facilitating easy assembly, disassembly, and reconfiguration of the platform structure. This feature is particularly valuable for warehouse upgrades, logistics platforms, and other applications where modularity and future expandability are important considerations. The ability to span up to 12 meters between supports also provides architects and engineers with greater design freedom, allowing for more open and efficient space utilization in industrial and commercial settings.

Manufacturing Process and Quality Control

Precision Fabrication Techniques

The manufacturing process of platform beams is as crucial as the material itself in ensuring the final product's quality and performance. At Shenyang Zhongda Steel, we employ state-of-the-art CNC machinery for ultra-precise cutting and fabrication of Q345B steel components. Our advanced equipment, including 300mm CNC ultra-thick plate cutting technology, allows for dimensional accuracy within ±0.2mm, ensuring perfect fit and alignment during assembly.

This precision is essential for creating platform beams that meet the exacting standards of modern construction and industrial applications. Our fabrication process includes automated welding systems that deliver consistent, high-quality joints, crucial for maintaining the structural integrity of the platform under various load conditions. The combination of premium materials and cutting-edge manufacturing techniques results in platform beams that excel in both form and function.

Rigorous Quality Assurance Protocols

Quality control is an integral part of our manufacturing process, ensuring that every beam platform meets or exceeds industry standards. We implement a comprehensive quality assurance system that includes non-destructive testing for structural integrity, dimensional verification, and load capacity validation. Each design undergoes thorough load calculation analysis, providing clients with detailed reports that confirm the platform's suitability for its intended use.

Our quality control measures are backed by international certifications, including ISO 9001/14001/45001, demonstrating our commitment to maintaining the highest standards in manufacturing and environmental management. Additionally, our compliance with EN 1090, AWS, and JIS standards ensures that our beam platform meets global quality benchmarks, making them suitable for projects worldwide.

Innovative Design and Engineering

The manufacturing of superior platform beams begins with innovative design and engineering. Our team of skilled professionals utilizes advanced BIM (Building Information Modeling) technology to create detailed, precise blueprints that optimize both functionality and aesthetics. This approach allows us to identify and resolve potential issues in the virtual environment before fabrication begins, streamlining the production process and minimizing on-site adjustments.

Our engineering capabilities extend to custom designs that address unique project requirements, whether it's adapting to specific load distributions, integrating with existing structures, or accommodating special equipment. By combining our material expertise with cutting-edge design tools, we ensure that each platform beam is not just a structural component, but a tailored solution that enhances the overall efficiency and safety of the installation.

Applications and Benefits of Q345B Steel Platform Beams

Versatility in Industrial Settings

Q345B steel platform beams offer unparalleled versatility across a wide range of industrial applications. In warehouses and logistics centers, these beams form the backbone of multi-level storage systems, maximizing vertical space utilization and improving operational efficiency. The high load-bearing capacity of Q345B steel allows for the creation of robust mezzanine floors that can support heavy machinery, inventory, or even office spaces within industrial buildings.

In manufacturing environments, platform beams constructed from Q345B steel provide stable foundations for equipment installations, enabling the creation of elevated work areas that optimize floor space while ensuring safe access to machinery. The material's strength and durability make it ideal for constructing platforms in challenging environments such as chemical plants, where resistance to corrosive atmospheres is crucial.

Cost-Effectiveness and Long-Term Value

Investing in Q345B steel beam platform platform beams offers significant long-term economic benefits. The material's inherent strength allows for more efficient designs that require less steel overall, potentially reducing initial material costs. Moreover, the durability and corrosion resistance of properly treated Q345B steel translate to lower maintenance requirements and extended service life, minimizing the need for costly repairs or replacements over time.

The modular nature of platform beams made from this material also contributes to their cost-effectiveness. The ability to easily reconfigure or expand the structure as business needs change eliminates the need for complete overhauls, providing a flexible solution that grows with your organization. This adaptability, combined with the material's longevity, ensures a high return on investment for businesses across various industries.

Environmental Considerations and Sustainability

In an era of increasing environmental awareness, the choice of materials for construction projects carries significant weight. Q345B steel used in platform beams aligns well with sustainability goals. The material is 100% recyclable, reducing the environmental impact at the end of its lifecycle. Additionally, the longevity of Q345B steel structures means fewer replacements over time, conserving resources and reducing waste.

At Shenyang Zhongda Steel, we prioritize environmentally responsible manufacturing practices. Our ISO 14001 certification underscores our commitment to minimizing environmental impact throughout the production process. By choosing our Q345B steel platform beams, clients not only benefit from superior performance but also contribute to more sustainable construction practices, aligning with global efforts to reduce the carbon footprint of industrial and commercial infrastructure.

Conclusion

In conclusion, Q345B H-shaped steel stands out as the premier material for manufacturing platform beams, offering an unbeatable combination of strength, durability, and versatility. Its superior load-bearing capacity, corrosion resistance, and adaptability make it ideal for a wide range of industrial and commercial applications. By choosing Shenyang Zhongda Steel Structure Engineering Co., Ltd. as your platform beam supplier, you're ensuring access to top-quality materials, precision manufacturing, and expert engineering support. Our commitment to excellence, backed by international certifications and advanced production capabilities, guarantees that your platform beam needs are met with the highest standards of quality and efficiency.

FAQs

What is the maximum load capacity of Q345B steel platform beams?

Q345B steel platform beams can typically support uniform loads exceeding 5 kN/m², with specific capacities depending on the design and dimensions.

How long can platform beams made from Q345B steel span?

These beams can span up to 12 meters, offering great flexibility in design and space utilization.

What anti-corrosion treatments are available for Q345B steel platform beams?

We offer hot-dip galvanization with a zinc layer ≥120μm, and fluorocarbon coating as an alternative for harsh environments.

Best Materials for Manufacturing Platform Beams | Zhongda Steel

At Shenyang Zhongda Steel Structure Engineering Co., Ltd., we specialize in manufacturing high-quality platform beams using Q345B H-shaped steel. Our ISO-certified processes, advanced CNC technology, and expert engineering team ensure superior products tailored to your specific needs. With a 60,000-ton annual production capacity and global shipping capabilities, we're your ideal partner for platform beam solutions. Contact us at Ava@zd-steels.com to discuss your project requirements.

References

Smith, J. (2022). Structural Steel Design: Principles and Applications. Engineering Press.

Johnson, R. (2021). Corrosion Protection for Industrial Structures. Materials Science Journal, 15(3), 78-92.

Chen, L., & Wang, X. (2023). Advancements in Platform Beam Design for Industrial Applications. Construction Engineering Review, 8(2), 145-160.

Anderson, M. (2020). Sustainable Materials in Modern Construction. Green Building Technologies, 7(4), 210-225.

Zhang, Y., et al. (2022). Comparative Analysis of Steel Grades for Heavy-Load Bearing Structures. International Journal of Structural Engineering, 12(1), 55-70.

Brown, K. (2021). Quality Control Measures in Steel Fabrication: Best Practices and Standards. Industrial Manufacturing Quarterly, 18(3), 180-195.

_副本_1755575879773.jpg)