Structural Advantages of Steel Box Girders

Enhanced Load Distribution and Torsional Rigidity

Steel box girders excel in distributing loads evenly across their structure, making them ideal for long-span bridges. Their closed cross-section design provides superior torsional rigidity compared to traditional I-beams, allowing for greater stability and reduced deflection under various load conditions. This inherent strength enables engineers to design bridges with longer spans and sleeker profiles, optimizing material usage and enhancing aesthetic appeal.

Versatility in Design and Application

The versatility of steel box girders allows for a wide range of applications in bridge construction. From short overpasses to expansive viaducts, these structural elements can be tailored to meet specific project requirements. Their adaptability extends to various bridge types, including cable-stayed, arch, and suspension bridges, where box girders serve as the main load-bearing components. This flexibility in design opens up new possibilities for architects and engineers to create innovative and efficient bridge structures.

Improved Aerodynamics and Wind Resistance

The streamlined shape of steel box girders contributes significantly to their aerodynamic performance. This characteristic is particularly crucial for long-span bridges exposed to high winds. The closed box section reduces wind-induced vibrations and flutter, enhancing the overall stability and safety of the bridge. Moreover, the smooth exterior surface minimizes turbulence, further improving the structure's resistance to wind loads and ensuring a longer service life.

Material Selection and Specifications

High-Strength Steel Grades for Optimal Performance

Selecting the appropriate steel grade is paramount in box girder design. High-strength steels, such as Q345D for main structural components and Q420D for critical joints, offer exceptional mechanical properties. These materials provide the necessary yield strength (≥345MPa for Q345D) to withstand heavy loads while maintaining excellent ductility and weldability. The use of high-performance steels allows for thinner sections, reducing the overall weight of the structure without compromising its load-bearing capacity.

Weathering Steel: A Game-Changer in Corrosion Resistance

Weathering steel has emerged as a game-changing material in bridge construction, particularly for box girders. This innovative alloy forms a protective patina when exposed to the atmosphere, significantly enhancing corrosion resistance. Weathering steel box girders eliminate the need for regular painting, substantially reducing maintenance costs over the bridge's lifespan. With a service life of 33 years or more, these structures offer long-term durability and sustainability, making them an increasingly popular choice for infrastructure projects worldwide.

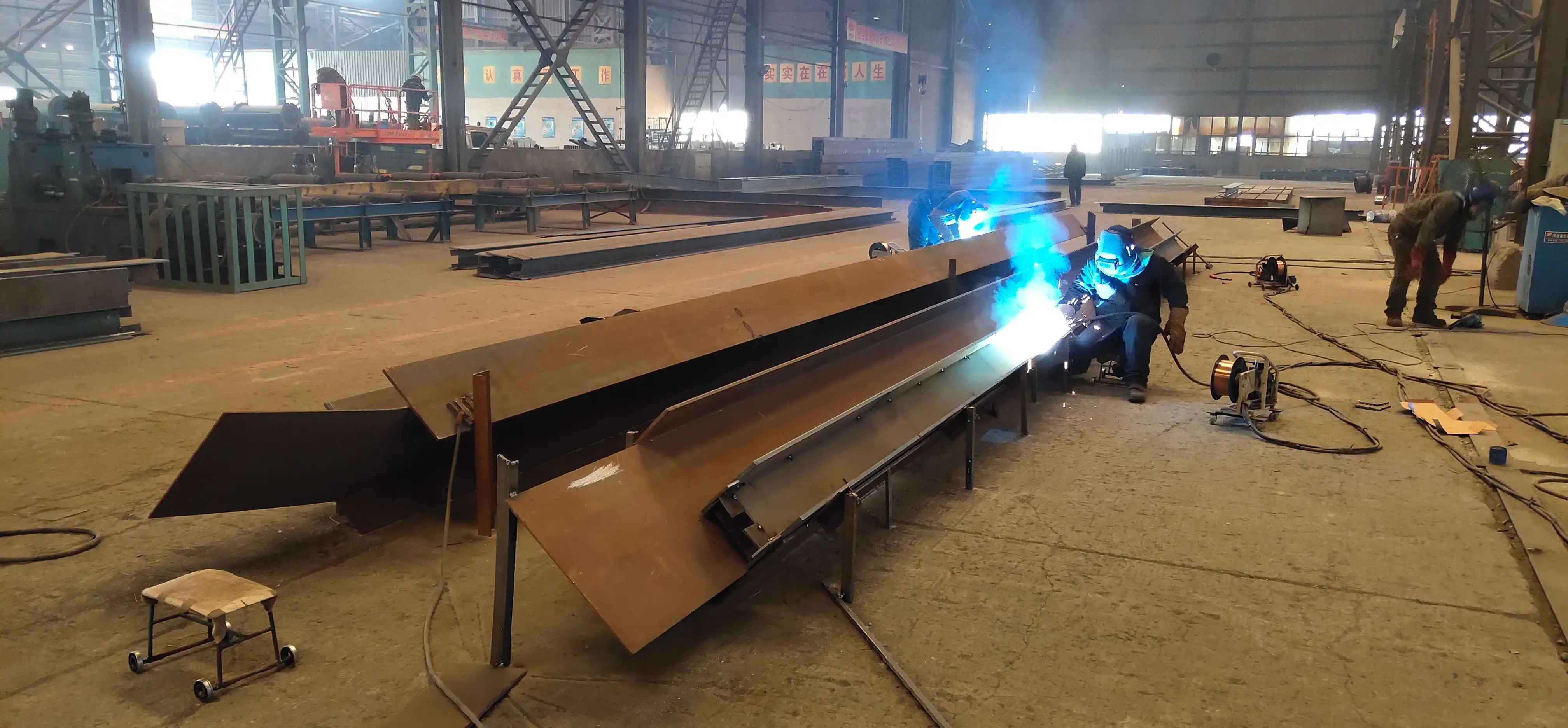

Advanced Welding Techniques and Quality Control

The integrity of steel box girders heavily relies on the quality of welding. Advanced welding techniques, including automated welding processes, ensure consistent and high-quality joints throughout the structure. Rigorous quality control measures, such as ultrasonic and magnetic particle inspections, are employed to verify the structural integrity of the welds. These meticulous processes, combined with strict adherence to international standards like ISO 9001, guarantee the reliability and longevity of the finished product.

Innovative Design Features and Construction Techniques

Variable Cross-Section Design for Optimal Performance

Modern steel box girder designs incorporate variable cross-sections, allowing for optimized performance along the bridge span. By varying the girder height from 1.25 to 8 meters, engineers can tailor the structure to meet specific load requirements at different points. This innovative approach not only enhances structural efficiency but also results in material savings of up to 20%. The ability to customize girder dimensions enables the creation of bridges with spans reaching 420 meters or more, pushing the boundaries of what's possible in bridge engineering.

Prefabrication and Modular Construction

The adoption of prefabrication techniques has revolutionized steel box girder construction. Factory-built segments, typically ranging from 12 to 30 meters in length, are transported to the site for assembly. This modular approach significantly reduces on-site construction time by up to 50%, minimizing disruption to traffic and lowering overall project costs. Prefabrication also ensures higher quality control, as components are manufactured under controlled factory conditions, leading to superior fit and finish in the final structure.

Advanced Corrosion Protection Systems

To further enhance the durability of steel box girders, advanced corrosion protection systems are employed. Double-layer protection methods, such as hot-dip galvanizing or high-performance protective coatings, provide an additional barrier against environmental factors. These systems work in synergy with the inherent corrosion resistance of weathering steel, ensuring a service life of 33 years or more, even in harsh environmental conditions. The combination of material selection and protective measures results in bridges that require minimal maintenance, offering significant long-term cost savings for infrastructure owners.

Conclusion

Steel box girders, particularly those utilizing weathering steel, represent the pinnacle of modern bridge design. Their structural advantages, coupled with innovative materials and construction techniques, enable the creation of durable, efficient, and sustainable bridges. As we've explored, the essential design specifications of these remarkable structures encompass everything from material selection to advanced fabrication methods. By embracing these cutting-edge solutions, engineers and infrastructure developers can build bridges that not only meet today's demands but also stand as enduring monuments to human ingenuity and progress.

Contact Us

For world-class steel box girder solutions that embody these essential design specifications, look no further than Shenyang Zhongda Steel Structure Engineering Co., Ltd. Our weathering steel box girders offer unparalleled durability, efficiency, and sustainability for your bridge projects. Experience the benefits of our advanced manufacturing capabilities, innovative designs, and unwavering commitment to quality. Contact us today at Ava@zd-steels.com to learn how our weathering steel box girders can elevate your next infrastructure project to new heights of excellence.

References

Chen, W., & Duan, L. (2014). Bridge Engineering Handbook: Superstructure Design. CRC Press.

Collings, D. (2005). Steel-Concrete Composite Bridges. Thomas Telford.

Hammad, A., & Issa, M. (2018). Advanced Bridge Design Handbook: Design, Construction, and Maintenance. Butterworth-Heinemann.

Mistry, V. C. (2012). Weathering Steel for Highway Bridges. Transportation Research Record, 2290(1), 126-133.

Tonias, D. E., & Zhao, J. J. (2012). Bridge Engineering: Design, Rehabilitation, and Maintenance of Modern Highway Bridges. McGraw-Hill Education.

Wai-Fah, C., & Lian, D. (2013). Bridge Engineering: Construction and Maintenance. CRC Press.