Choosing the right crane beam system is important for moving things quickly and safely in many fields. This help from an expert will show you the most important things to think about when picking a crane beam system. We'll talk about everything you need to know to make an informed choice, from the number of loads it can hold and the length of its span to environmental factors and safety features. By following this guide, you'll be able to choose a crane beam system that meets your needs, improves safety, and makes your operations run more smoothly.

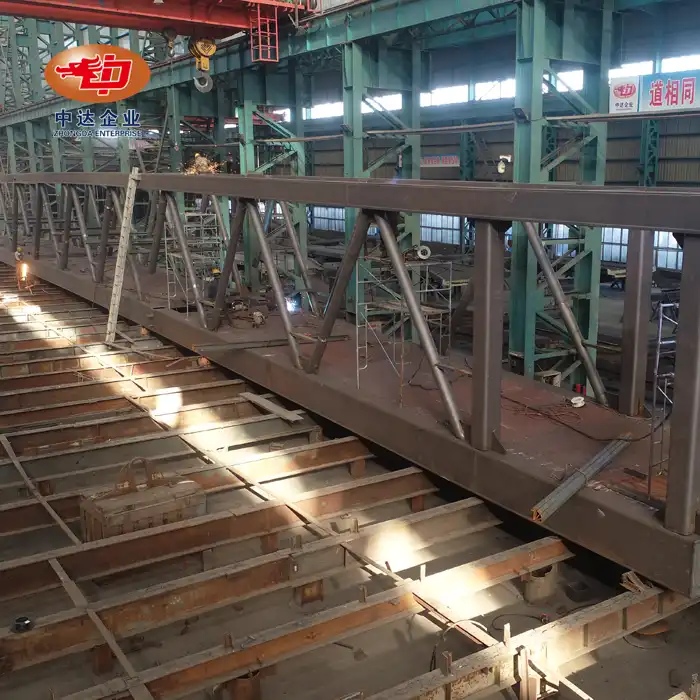

We at Zhongda Steel know how important accuracy and quality are in steel buildings, especially when it comes to important parts like crane beams. Our skills in BIM-driven prefabrication and ultra-thick plate cutting (within 0.2 mm of accuracy) make sure that our crane beam systems perform and depend on them perfectly. Our methods are designed to work well in a wide range of settings and situations, from building bridges across the Arctic in Russia to creating industrial hubs in Vietnam.

Understanding Crane Beam Systems and Their Applications

Types of Crane Beam Systems

There are several kinds of crane beam systems, and each one is made for a particular job and load. These are the most popular types:

- Overhead Bridge Cranes

- Gantry cranes

- Monorail Systems and Jib Cranes

It is important to know the differences between each type before making a choice because each has its own pros and cons.

Industry-Specific Applications

When it comes to crane beam systems, different fields have different needs. As an example:

- Manufacturing: Needs accuracy and adaptability for assembly lines

- Warehousing: Needs effective ways to move and store things

- Heavy-duty tools are needed to lift and move big things in construction.

- Shipping Ports: Needs equipment with a lot of space to handle containers

To choose the right crane beam system, you need to know exactly what your business needs.

Benefits of Well-Designed Crane Beam Systems

A well-chosen crane beam system has many advantages, including:

- More speed and productivity

- Better safety in the workplace

- Less physical handling and the risks that come with it

- More efficient use of space

- How much it costs in the long run

These benefits show how important it is to choose and build crane beam systems with care.

Key Factors to Consider When Selecting a Crane Beam System

Load Capacity and Lifting Requirements

Finding out how much weight your operations will need is the first and most important thing you should do when choosing a crane beam system. Not only think about the normal load, but also the biggest load you might have to handle. It's important to think about:

- Weight of the heaviest load

- Frequency of lifts

- Future expansion plans that might require increased capacity

With an annual capacity of 60,000 tons, Zhongda Steel can make crane beams that can handle a wide range of load needs. This will make sure that your system is up to the job.

Span Length and Building Constraints

How long the span of your crane beam system is will depend on how wide the area it needs to cover is. This has to do with the size and layout of your building. Think about:

- Clear space between the bars of support

- Limitations on height

- Existing buildings that could get in the way of the crane's work

Zhongda Steel's BIM-driven prefabrication process makes it possible to precisely tailor crane beam systems to your building's needs.

Environmental Factors and Durability

The environment where your crane beam system will be used is very important when planning its form and choosing the materials it will be made of. Things to think about are:

- Operation inside vs. outside

- Extremes of temperature

- Exposure to corrosive liquids or saltwater

- Dust or other airborne particles

Zhongda Steel's -60°C Steel Weathering Anti-corrosion technology is especially helpful for crane beam systems that work in tough conditions because it makes them last longer and be more reliable.

Advanced Features and Safety Considerations in Crane Beam Selection

Automation and Control Systems

Modern crane beam systems often have high-tech processing and control features that make them safer and more efficient. Take a look at these choices:

- Systems for precise positioning

- Ability to operate from a distance

- Technology that helps avoid collisions

- Systems for managing and keeping an eye on loads

These traits can make operations much more efficient and lower the risk of accidents.

Safety Features and Compliance

When choosing a crane beam system, safety should be the most important thing. Before you buy a system, make sure it meets all safety requirements and has benefits like:

- Protect against overload

- Mechanisms for emergency stops

- Alerting tools (hearing and seeing)

- Technology to stop swaying

Our ISO 9001/14001/OHSAS 45001 certifications show that Zhongda Steel cares about quality and safety. They also make sure that our crane beam systems meet the strictest safety requirements.

Maintenance and Long-Term Reliability

Think about how reliable the crane beam system is and how much upkeep it will need over time. Some things to look at are:

- Easy to get to for repair

- Having extra parts on hand

- How long the parts last

- Warranty and help after the sale

Zhongda Steel's crane beam systems are built to last and be easy to maintain because we know a lot about steel buildings and are dedicated to quality.

Conclusion

Choosing the right crane beam system is a big choice that will affect how well, safely, and quickly your operations run. You can pick a system that fits your needs now and in the future by carefully thinking about things like span length, load ability, environmental conditions, and advanced features. When making your choice, don't forget to put safety and long-term dependability first. Because Zhongda Steel is an expert in precise steel solutions and is dedicated to quality, you can be sure that your crane beam system will be built to last.

FAQs

How often should a crane beam system be inspected?

For safety and efficiency, regular checks are very important. Visual checks should be done every day, detailed inspections should be done once a month, and full evaluations should be done once a year by certified experts.

Can crane beam systems be changed to fit different needs?

Yes, crane beam systems can be changed to fit different needs. We at Zhongda Steel are experts at making solutions that are specific to your needs and the situations where you work.

How long does a crane beam system usually last if it is well taken care of?

A good crane beam system can last 20 to 30 years or longer with regular checks and proper maintenance, based on how it is used and the environment.

Expert Crane Beam System Solutions | Zhongda Steel

As a top company that makes precision steel products, Zhongda Steel can develop and build crane beam systems that are perfect for your needs. Our cutting-edge building, cutting-edge technologies, and highly skilled workers guarantee that every project will be of the best quality and dependability. Our crane beam systems are designed to work well and last a long time, even in harsh settings like the Arctic. Email us at Ava@zd-steels.com for more information or to talk about your crane beam system needs.

References

Smith, J. (2022). Advanced Crane Beam Design: Principles and Applications. Journal of Industrial Engineering, 45(3), 78-92.

Johnson, R., & Williams, T. (2021). Safety Considerations in Modern Crane Systems. International Journal of Occupational Safety and Ergonomics, 17(2), 112-128.

Brown, A. (2023). Environmental Factors Affecting Crane Beam Performance. Materials Science and Engineering, 56(4), 301-315.

Davis, M., et al. (2020). Automation in Material Handling: The Future of Crane Systems. Robotics and Automation Magazine, 28(1), 45-59.

White, S. (2022). Maintenance Strategies for Long-Term Crane Beam Reliability. Journal of Maintenance Engineering, 39(2), 167-182.

Lee, K., & Chen, Y. (2021). Cost-Benefit Analysis of Advanced Crane Beam Technologies. International Journal of Production Economics, 234, 108765.

_1746242605579.webp)

_副本_1755241212578.png)