Understanding Non-Destructive Testing Methods for Steel Welds

Visual Inspection: The First Line of Defense

Visual inspection serves as the most fundamental and essential non-destructive testing (NDT) method. This technique involves a thorough examination of welds using the naked eye, often aided by basic tools such as magnifying glasses or mirrors to enhance visibility. It is highly effective for identifying a variety of surface anomalies, including cracks, porosity, undercut, and improper weld geometry or size. As a primary screening tool, it is exceptionally cost-effective, rapid to perform, and requires minimal specialized training. However, its significant limitation is that it can only detect flaws that are open to the surface, providing no information about internal weld integrity or sub-surface discontinuities.

Penetrant Testing: Revealing Surface Flaws

Penetrant testing is a highly sensitive method specifically designed for locating surface-breaking defects in non-porous materials such as steel structure. The process begins with the application of a brightly colored or fluorescent liquid penetrant to the cleaned weld surface of the steel structure. This liquid is given time to seep into any fine cracks or openings in the steel structure by capillary action. After the excess penetrant is carefully removed, a developer is applied to the steel structure, which acts like a blotter, drawing the trapped penetrant back to the surface. This action creates a clear, visible indication of the flaw on the steel structure under normal or ultraviolet light, revealing defects that are often invisible to the naked eye.

Magnetic Particle Inspection: Detecting Near-Surface Discontinuities

Magnetic particle inspection is a versatile NDT method exclusively used for ferromagnetic materials. The process requires magnetizing the weld area, creating a magnetic field within the component. When a surface or near-surface discontinuity (like a crack) is present, it interrupts this field, causing magnetic flux leakage at the defect site. Fine iron particles, applied dry or in a liquid suspension, are then attracted to this leakage zone, forming a visible accumulation that outlines the flaw. This technique is prized for its ability to detect both open surface flaws and those lying just beneath the surface, providing a critical advantage over visual and penetrant testing for certain applications.

Advanced NDT Techniques for Comprehensive Weld Evaluation

Ultrasonic Testing: Probing the Depths

Ultrasonic Testing (UT) is a non-destructive testing method that employs high-frequency sound waves to inspect and detect internal flaws within welds. A significant advantage is its effectiveness on thick materials, as it can probe through the entire weld thickness to locate imperfections. However, the technique is highly dependent on skilled operators to correctly interpret the signals from the equipment. When performed expertly, it yields exceptionally detailed information, providing precise data on the size, location, and orientation of defects like cracks or lack of fusion, which is crucial for structural integrity assessments.

Radiographic Testing: X-Ray Vision for Welds

Radiographic Testing (RT) involves the use of X-rays or gamma rays to penetrate the steel structure weld and produce a two-dimensional image of its internal structure on film or a digital detector. This image can reveal a wide range of internal defects such as porosity, slag inclusions, and incomplete fusion. A key benefit is that it creates a permanent visual record of the steel structure weld's condition for future reference and analysis. Nonetheless, the process requires significant safety precautions to protect personnel from radiation exposure, involves specialized and often costly equipment, and access to both sides of the steel structure component is typically needed.

Eddy Current Testing: Detecting Surface and Near-Surface Flaws

Eddy Current Testing (ECT) is an electromagnetic technique used to identify surface and near-surface flaws in materials that conduct electricity. By inducing circular electrical currents (eddy currents) in the test material, it can detect disruptions caused by defects such as fine cracks, corrosion, or changes in material thickness. A major operational advantage is that it is a fast inspection method and does not require direct contact with the weld surface, making it highly efficient. However, its effectiveness is generally limited to surface or subsurface flaws and is influenced by the material's conductivity and permeability.

Implementing NDT in Your Steel Structure Projects

Choosing the Right NDT Method

Selecting the correct Non-Destructive Testing (NDT) method is key to ensuring reliable inspection outcomes. Different techniques - such as ultrasonic testing (UT), magnetic particle testing (MT), radiographic testing (RT), and dye penetrant testing (PT) - offer unique advantages depending on the structure's material, weld type, and expected flaw characteristics. At Zhongda Steel, our engineers carefully evaluate each project's technical requirements and environmental conditions to recommend the most suitable combination of NDT methods, ensuring comprehensive coverage and precise detection of any potential imperfections in welds or materials.

Preparing for NDT: Surface Preparation and Access

Accurate NDT results depend heavily on the quality of steel structure surface preparation and accessibility. Before testing, surfaces must be free from contaminants such as rust, oil, paint, and welding residues that may obscure indications. Depending on the inspection method, surfaces are cleaned, ground, or coated with appropriate testing media. Zhongda Steel's technicians ensure all critical weld areas are accessible and properly prepared for inspection. This meticulous approach guarantees that NDT instruments can operate effectively, allowing for accurate signal interpretation and reliable assessment of weld integrity.

Interpreting and Documenting NDT Results

The accurate interpretation of NDT results requires both technical skill and experience. Trained inspectors at Zhongda Steel carefully analyze test data to distinguish between acceptable variations and true structural defects. Every finding is meticulously documented, including the defect's type, size, and precise location. This comprehensive reporting ensures full traceability and supports data-driven decisions on weld acceptance, repair, or further testing. Through systematic documentation and quality review, we help clients maintain compliance with international standards while ensuring long-term structural safety and performance.

Conclusion

Conducting non-destructive tests on steel structure welds is a critical aspect of ensuring structural integrity and safety. By employing a combination of visual inspection, surface testing methods like penetrant and magnetic particle testing, and advanced techniques such as ultrasonic and radiographic testing, you can comprehensively evaluate weld quality. At Shenyang Zhongda Steel Structure Co., Ltd., we emphasize the importance of thorough NDT in our steel fabrication processes, ensuring that our structures meet the highest standards of quality and reliability.

FAQs

1. How often should non-destructive tests be conducted on steel structure welds?

The frequency depends on factors such as the structure's criticality, environmental conditions, and regulatory requirements. Generally, initial testing is done during fabrication, with periodic inspections throughout the structure's lifecycle.

2. Can NDT detect all types of weld defects?

While NDT methods are highly effective, no single method can detect all types of defects. A combination of techniques is often used for comprehensive inspection.

3. Is NDT necessary for all welded structures?

NDT is crucial for structures where weld failure could lead to significant safety risks or economic losses. It's particularly important in industries such as construction, aerospace, and oil and gas.

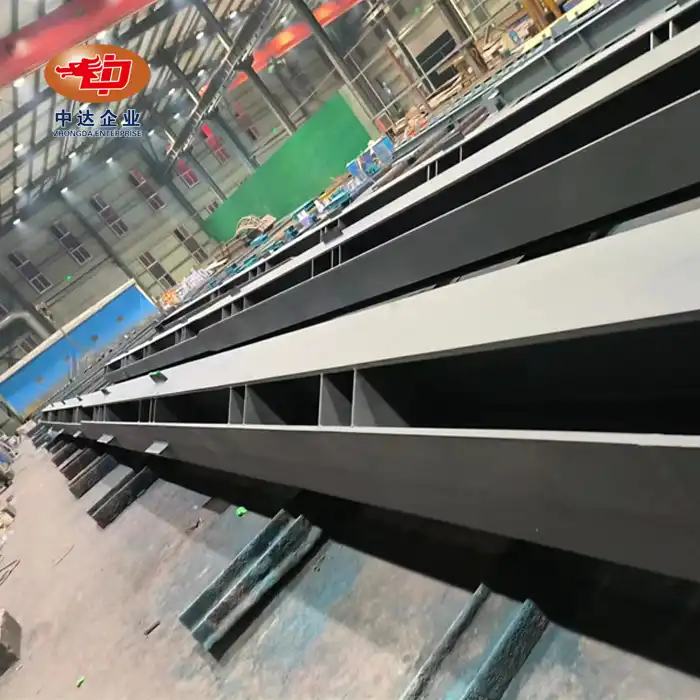

Expert Steel Structure Welding and NDT Services | Zhongda Steel

At Shenyang Zhongda Steel Structure Co., Ltd., we offer comprehensive steel structure solutions, including expert welding and non-destructive testing services. As a leading steel structure manufacturer, we ensure the highest quality and safety standards in all our projects. For professional NDT services or custom steel fabrication, contact our experienced team at Ava@zd-steels.com.

References

1. American Welding Society. (2020). "Welding Inspection Handbook."

2. International Institute of Welding. (2019). "Guidelines for Non-Destructive Testing of Welded Structures."

3. Journal of Nondestructive Evaluation. (2021). "Advances in Non-Destructive Testing for Steel Structures."

4. American Society for Nondestructive Testing. (2022). "NDT Handbook: Volume 1, Visual Testing."

5. Structural Integrity Associates. (2018). "Best Practices in Weld Inspection for Steel Structures."

6. Materials Evaluation Journal. (2020). "Comparative Analysis of NDT Methods for Steel Weld Inspection."

_副本_1753167843741.webp)