Steel truss bridges are complex structures that are built using new ideas and cutting-edge materials to make sure they can span long distances. These buildings use triangular frames that are linked together to spread out loads over long distances. This makes them an important part of modern transportation networks. For bridge spans of 30 to 150 meters, engineers use modular building methods that guarantee strength and save money while looking at load distribution patterns and choosing top-notch materials like ASTM A709 Gr.50 steel.

Understanding the Fundamentals of Steel Truss Bridge Design

The key to good long-span bridge design is knowing how trusses act when different types of weight are put on them. Modern steel truss bridges use the natural power of triangular shapes. The connecting parts of the bridge work together to keep the whole structure from falling apart under pushing and pulling forces.

Core Components and Material Selection

Each high-performance bridge starts with carefully chosen parts that make up the structure's backbone. The main parts are the top and bottom chords, which bend, the vertical and diagonal web members, which split, and the connection nodes, which link the parts and share the load. Choosing the right material is very important for long-span performance. ASTM A709 Gr.50 steel has amazing strength and Z35 Z-direction qualities that keep lamellar tears from happening in dynamic loading situations.

Advanced materials are tested very carefully to make sure they meet strict performance standards. The bridge's ability to handle Highway-I level loading conditions with maximum capacities hitting 100 tons depends on the steel's chemical makeup and its mechanical qualities. This material standard makes sure that it works well in a range of settings and keeps the structure intact over long periods of time.

Truss Configuration Options

Engineers choose from a range of truss configurations depending on the needs of the project and how the span is shaped. Warren trusses have lateral members that take turns facing one way and the other, without any vertical posts. This design is great for saving materials on medium to long lengths. Pratt trusses have diagonals and vertical parts. This makes the structure stronger and better at distributing weight, which works well for heavy-duty uses that need to be able to hold a lot of weight.

Each arrangement has its own benefits based on what it will be used for. Warren trusses are best for quick, modular building. Pratt designs are better for bridges that experience changing loads and weather pressures.

Structural Engineering Considerations and Calculations

In-depth structural analysis is the most important part of designing a good long-span steel truss bridge. It needs to look at a lot of different load situations and external factors that affect how the structure performs over its lifetime.

Load Analysis and Distribution Mechanisms

Engineers have to think about the different types of weight that can affect how well the bridge works when it is in use. While live loads include changing traffic patterns, foot traffic, and the placement of equipment, dead loads consist of the unchanging weight of deck systems, structural parts, and fixed installations. When you factor in things like wind, earthquakes, temperature changes, and the possibility of ice forming, it becomes a lot harder to predict how a structure will behave.

When figuring out load distribution, the truss network and how forces move through it must be taken into account using very advanced math. The triangular shape of truss design means that when weight is added at any point, it will be efficiently passed to the support points through the mix of compression and tension forces in each part. This method of spreading lets long buildings carry heavy loads without bending too much or creating areas of high stress.

Quality Assurance and Inspection Protocols

To keep the structure stability, the manufacturing and fitting method needs to include thorough checking steps. Before the system is put together, advanced non-destructive testing methods make sure that each part meets strict quality standards.

Quality control standards include a number of different testing methods that check the strength of the materials and the performance of the joints. These strict steps include

Magnetic Particle Testing (MT) looks for breaks in the surface or near the surface of ferromagnetic materials. This makes sure that all parts of a structure are well-welded and made of good metal.

Ultrasonic Testing (UT) uses high-frequency sound waves to check the state of a material's inside and find possible flaws that could hurt long-term performance.

Full-node inspection methods look at each link point where structure parts move forces. These methods make sure that the whole system can handle the loads correctly.

These inspection procedures make sure that they meet global standards, such as ISO 9001, and provide proof that supports the planning of long-term upkeep and structure health tracking programs.

Comparing Steel Truss Bridges with Other Bridge Types for Long Spans

When considering choices for long-span building projects, steel truss bridge designs have very useful benefits that make them the most suitable choice for many situations that need long reach and heavy-duty performance.

Performance Advantages Over Alternative Materials

Steel trusses have better strength-to-weight ratios than concrete ones. This allows for longer lengths with fewer base needs and lower costs for the whole project. When you use modular steel construction, you can make the big parts of the building in a workshop where you can control the environment. This makes sure that the quality is always high, and it also means that you don't have to wait for good weather to finish the project.

Durability tests show that steel buildings with the right design are much better at staying intact. With current covering systems, advanced anti-corrosion processes greatly extend the service life of materials beyond what was thought possible, giving them solid security for decades against damage from the environment. Using 160μm of thermal spray zinc, an epoxy mica middle covering, and a polyurethane top coat forms a multi-layer defense system that protects the structure in any kind of weather.

Economic and Operational Benefits

Long-term running costs favor steel truss designs because they are easy to keep and their parts can be replaced. Unlike concrete buildings that may need a lot of work to fix them after they get damaged, steel bridges can be fixed in a way that targets the problem and replaces parts. This lowers the cost of the service's lifetime and keeps it running.

The ability to quickly put together flexible steel systems is a big help for jobs that need to be done quickly. This ability can be seen in emergency bridge uses. Their removable designs allow for the installation of 200-meter spans in about 50 hours, which shows that infrastructure can be put in place quickly when needs appear suddenly.

Procurement and Custom Fabrication of Steel Truss Bridges

To ensure project success and long-term performance stability, manufacturers' skills, quality standards, and technical knowledge must be carefully studied during purchase.

Manufacturer Selection Criteria

There are a lot of things that affect both the short-term and long-term needs of a steel truss bridge project, and these things must be considered when picking a manufacturing partner. Key factors for evaluation are agreement with ISO certification, output capacity, and proven experience with similar projects that need similar technical specs.

Manufacturing centers need to have enough space to work on big projects in an efficient way. Today's factories with a 60,000-ton yearly capacity and advanced cranes that can lift 50-ton parts make sure that heavy-duty materials needed for long-span uses are processed without a hitch. These skills let producers keep the quality up while meeting tight delivery deadlines.

Customization and Turnkey Solutions

Advanced manufacturing skills make it possible to fully customize things so that they meet the needs of the project and the conditions at the site. With turnkey solutions, customers have single-source duty and efficient project management for the whole project lifecycle, from initial design input through final installation and approval.

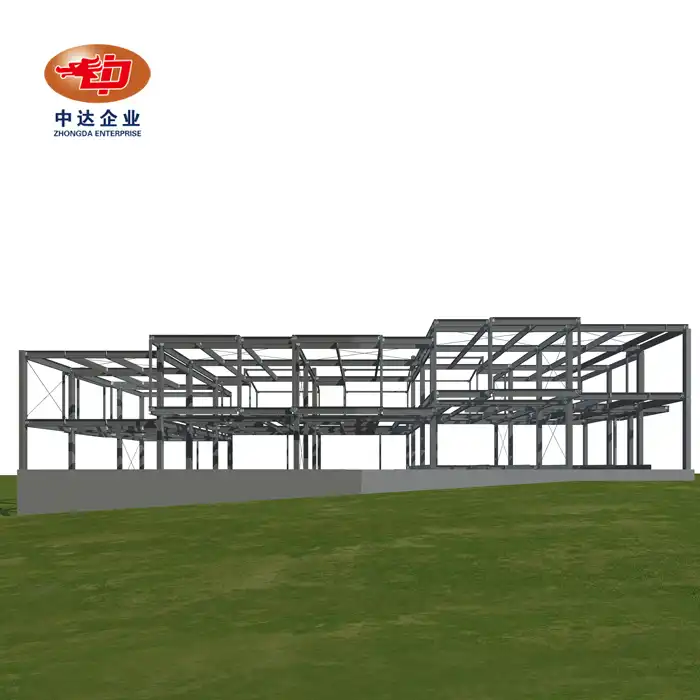

The custom manufacturing method keeps the strength and performance of the structure intact while allowing the span length to change between 30 and 150 meters. Engineers can make trusses work better by optimizing things like a truss's shape, the size of its members, and its link details. This can help meet certain load capacity standards while also using less material and making the build easier.

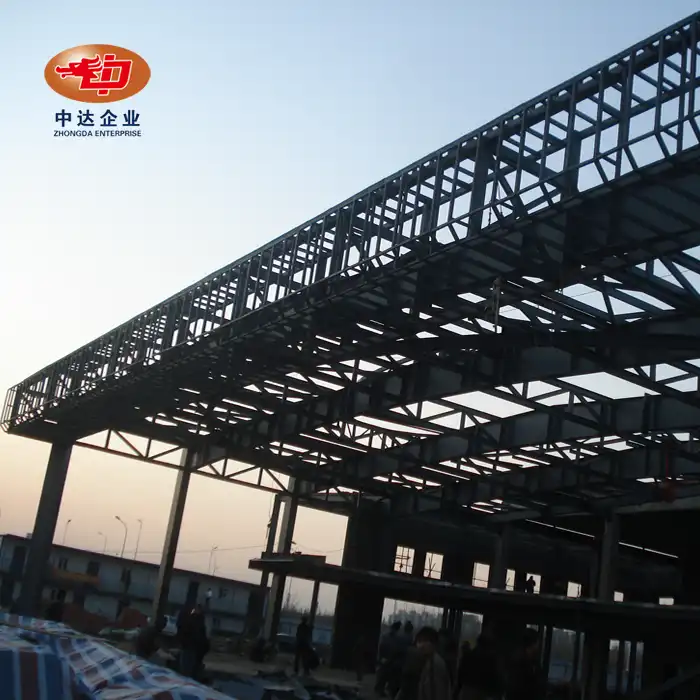

Company Introduction and Our Turnkey Steel Truss Bridge Solutions

For twenty years, Shenyang Zhongda Steel Structure Engineering Co., Ltd. has been providing building projects around the world with amazing and inventive engineering as a top maker of heavy-duty bridge parts. Our company, which was founded in 2004 and is based in the Shenyang Economic-Technological Development Zone, has become a world-certified leader in precision steel solutions.

Manufacturing Excellence and Capabilities

Our new 120,000 m² building is the height of current steel production technology. It has high-tech BIM-driven prefabrication tools and can cut ultra-thick plates with an exact range of ±0.2mm. With a yearly production capacity of 60,000 tons, the plant can handle big orders while keeping a close eye on quality at every stage of production.

For spans of 30 to 150 meters, our steel truss bridges with flexible Warren and Pratt truss setups get the job done. ASTM A709 Gr.50 steel was used to build these buildings because its Z35 Z-direction performance traits keep it from lamellar breaking even when the load conditions are tough. The use of 160μm zinc spray, epoxy mica, and polyurethane finish are examples of advanced anti-corrosion protection methods that make sure the service life is longer in a variety of weather conditions.

Quality Assurance and Certifications

Our production process, from getting materials to transport and installation, is controlled by strict quality checks at every stage. Our steel truss bridges are inspected with the latest Magnetic Particle Testing and Ultrasonic Testing technologies at every link point to make sure they are safe. These steps make sure that foreign standards are followed. These include ISO 9001, ISO 14001, ISO 45001, EN 1090, AWS, and JIS.

Our history of successful work includes more than 60 major projects, such as the 18,000-ton Shenyang Dongta Cross-Hunhe River Bridge and several large-scale infrastructure projects for CSCEC, CCCC, and China Railway. This experience shows that we can provide difficult tech solutions that meet the most exacting performance standards.

Conclusion

With smart engineering that makes sure the bridge is safe and reliable while using materials in the most efficient way, steel truss bridges work amazingly well over long spans. Using modern materials, tried-and-true design methods, and strict quality control makes infrastructure that can meet the needs of different projects in a range of industries. Today’s manufacturing methods make it possible to customize and quickly build things that can be used for both planned infrastructure growth and emergency reaction. Understanding these design principles gives procurement professionals the power to make smart choices that meet performance needs and keep costs in mind while making sure that long-term stability and business success are not compromised.

FAQs

What determines the longest span that can be made with steel truss bridges?

Maximum span length varies on a number of important things, such as how the truss is set up, how big the members are, what the materials are like, and what the loading needs are. Using strong materials like ASTM A709 Gr.50 steel, modern steel truss designs can build lengths up to 150 meters. These designs also keep their load capacities suitable for Highway-I level traffic, with maximum loads of 100 tons.

How do the upkeep needs of steel truss bridges differ from those made of concrete?

It is usually easier to fix steel truss bridges and repair their parts, but they need to be checked more often than concrete ones. Advanced anti-corrosion methods lower the need for care by a lot, and flexible design lets you do focused fixes without major service interruptions.

Which testing methods are best for making sure the structure stays sound over the long term?

Magnetic Particle Testing (MT) finds defects on the surface, Ultrasonic Testing (UT) checks the material inside, and full-node inspection methods look at all of the connection points. These techniques find possible problems before they affect how well the structure works.

Partner with Zhongda for Your Next Steel Truss Bridge Project

Zhongda Steel Structure Engineering uses both cutting-edge engineering and manufacturing that is known for its quality to make top-of-the-line, heavy-duty bridges. We can help you with building projects that need to meet strict budget and schedule standards while still getting the best results. This is because we have a lot of experience with long-span steel truss bridge design and construction. We offer full solutions that simplify projects without lowering quality. Our extensive skills in planning, manufacturing, and installation make this possible.

Our tech team is ready to talk with you about your project needs and come up with custom solutions that take into account how the project site will be used. Our flexible method gets great results and speeds up delivery times in ways that other companies can't. This is true whether you need standard setups or custom emergency bridge systems. To talk about how our knowledge of making steel truss bridges can help with your next building project, please email us at Ava@zd-steels.com.

References

American Association of State Highway and Transportation Officials. "LRFD Bridge Design Specifications, 9th Edition." AASHTO Publications, 2020.

Connor, Robert J., et al. "Manual for Design, Construction, and Maintenance of Orthotropic Steel Deck Bridges." Federal Highway Administration, 2019.

Kulicki, John M., and David R. Mertz. "Load and Resistance Factor Design of Steel Highway Bridges." AISC Design Guide Series No. 31, 2018.

Taly, Narendra. "Design of Modern Highway Bridges." McGraw-Hill Professional, 2017.

Wright, William J., and Michael P. Engesser. "Steel Bridge Design Handbook: Truss Bridges." Federal Highway Administration, 2020.

Zhao, Zhongwei, and Hanbin Ge. "Fatigue Design of Steel and Steel-Concrete Composite Bridges." Elsevier Academic Press, 2021.

_副本_1755575879773.jpg)