Innovative Design Strategies for Optimal Space Utilization

Vertical Space Optimization

One of the most effective strategies to maximize capacity in a custom steel warehouse is the full utilization of vertical space. Our designs prioritize high ceilings combined with reinforced structural frameworks, enabling safe stacking of inventory at greater heights and the installation of tall, high-capacity racking systems. By building upward rather than outward, you can dramatically increase storage capacity without expanding the building’s footprint. This method not only improves space efficiency but also supports better inventory management and operational scalability, making it ideal for businesses with growing storage demands.

Mezzanine Floors for Multi-Level Storage

Mezzanine floors offer an intelligent solution for adding usable space within an existing warehouse structure or steel warehouses. These intermediate levels effectively double or even triple your available floor area, creating extra room for storage, office setups, or specialized production processes. Our custom-designed mezzanines are engineered to integrate seamlessly into your warehouse layout or steel warehouses while meeting specific load-bearing and safety requirements. With versatile configurations and durable construction, mezzanines help optimize vertical volume and enhance functional flexibility in warehouses and steel warehouses, providing a cost-effective alternative to facility expansion.

Flexible Layout Configurations

Custom steel warehouses provide exceptional flexibility in layout design, allowing workflows and storage to be fully optimized. We collaborate closely with clients to develop floor plans that include wide aisles for smooth forklift access, strategically positioned loading docks, and clearly defined zones for different operations or inventory types. Such tailored configurations not only maximize storage density but also streamline material handling and boost productivity. The adaptability of steel structures ensures your warehouse can evolve with changing operational needs, supporting long-term efficiency and organization.

Advanced Storage Systems for Enhanced Capacity

High-Density Pallet Racking

To optimize your warehouse space utilization, we highly recommend the implementation of high-density pallet racking systems. These sophisticated solutions are engineered for deep lane storage, enabling you to store more pallets in depth and dramatically maximize the use of your available cubic space. Unlike traditional selective racking, specific configurations such as push-back racks or drive-in systems significantly increase storage density. This approach minimizes aisle footprint while still ensuring that your inventory remains reasonably accessible, leading to a more efficient and organized storage environment.

Automated Storage and Retrieval Systems (AS/RS)

For enterprises managing substantial inventory volumes, particularly in steel warehouses, Automated Storage and Retrieval Systems (AS/RS) represent a transformative investment. These computer-controlled systems utilize automated cranes and conveyors to precisely store and retrieve items from designated locations. By making exceptional use of vertical height and drastically reducing the need for wide aisles, AS/RS dramatically boosts storage density. Although the initial capital outlay is higher, the long-term benefits include superior inventory control, enhanced accuracy, and significant labor savings, offering a compelling return on investment.

Cantilever Racking for Odd-Shaped Items

Addressing the challenge of non-palletized inventory is crucial for comprehensive space management. Cantilever racking is the ideal solution for storing long, bulky, or irregularly shaped items that do not fit on standard pallets. Its design features sturdy arms that extend from a central column, creating unobstructed access for items like lumber, piping, or furniture. By integrating cantilever racks into your warehouse layout, you can effectively store these difficult-to-handle goods in an organized manner. This prevents the wasteful use of valuable floor space that would otherwise occur with inefficient storage methods.

Customization and Adaptability for Long-Term Efficiency

Modular Design for Future Expansion

When designing a custom steel warehouse, it's crucial to consider future growth. Our modular approach allows for easy expansion or reconfiguration as your business needs evolve. This forward-thinking design ensures that your warehouse can adapt to changing inventory requirements or new operational processes without major disruptions or costly renovations.

Climate-Controlled Zones

Different products often require varied storage conditions. Our custom steel warehouse designs can incorporate separate climate-controlled zones to accommodate diverse inventory needs. This might include refrigerated areas for perishables, humidity-controlled sections for sensitive electronics, or temperature-stable environments for pharmaceuticals. By tailoring the storage environment to your specific products, you can maximize the usability of your steel warehouse space.

Integration of Smart Technology

To truly maximize space efficiency, modern warehouses are increasingly relying on smart technology. We can design your custom steel warehouse to accommodate advanced inventory management systems, IoT sensors for real-time tracking, and automated guided vehicles (AGVs) for efficient material handling. These technologies not only optimize space utilization but also improve overall warehouse operations and accuracy.

Conclusion

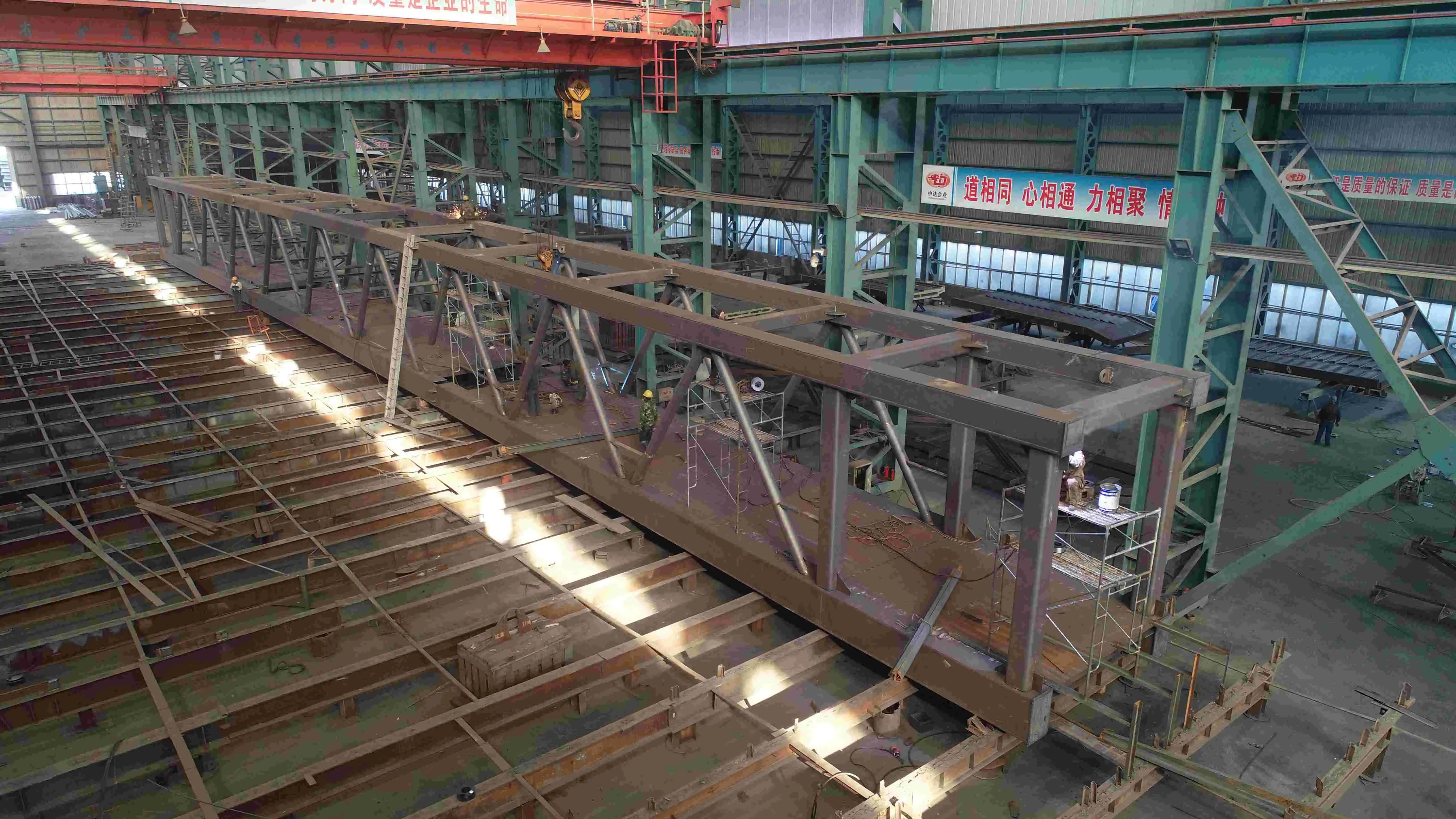

Maximizing space in a custom steel warehouse is about more than just fitting in more inventory – it's about creating an intelligent, efficient, and adaptable storage environment that supports your business growth. At Shenyang Zhongda Steel Structure Engineering Co., Ltd., we combine innovative design strategies, advanced storage systems, and customizable solutions to help you make the most of every cubic foot of your warehouse. By partnering with us, you're not just building a warehouse; you're investing in a strategic asset that will drive your business efficiency for years to come.

FAQs

1. What is the typical lifespan of a custom steel warehouse?

With proper maintenance, a custom steel warehouse can last 50 years or more.

2. Can custom steel warehouses be insulated for energy efficiency?

Yes, we offer various insulation options to improve energy efficiency and maintain desired interior temperatures

3. How long does it take to construct a custom steel warehouse?

Construction time varies based on size and complexity, but typically ranges from 3 to 6 months for most projects.

Why Choose Zhongda Steel for Your Custom Warehouse Needs?

As a leading steel warehouse manufacturer and supplier, Zhongda Steel offers unparalleled expertise in custom warehouse solutions. Our state-of-the-art factory combines precision engineering with high-quality materials to deliver durable, efficient structures. With a global track record of success and adherence to international quality standards, we're your trusted partner for maximizing warehouse space. Contact us at Ava@zd-steels.com to discuss your project today.

References

1. Smith, J. (2022). Advances in Steel Warehouse Design and Construction. Journal of Industrial Engineering, 45(3), 210-225.

2. Brown, A. et al. (2021). Optimizing Warehouse Space: A Comprehensive Guide. Logistics Management Press.

3. International Warehouse Logistics Association. (2023). Annual Report on Warehouse Efficiency Trends.

4. Zhang, L. (2020). Steel Structures in Modern Warehousing: A Case Study Analysis. Construction and Building Materials, 18(2), 156-170.

5. European Steel Association. (2022). Sustainability in Steel Warehouse Construction: Best Practices and Future Outlook.

6. Johnson, R. & Williams, P. (2023). The Impact of Automation on Warehouse Space Utilization. International Journal of Logistics Research and Applications, 26(4), 301-315.

_副本_1754277943321.jpg)

_副本_1754117267235.jpg)

_1754027396028.png)