Understanding OEM/ODM Crane Beam Solutions

What are OEM/ODM Crane Beam Solutions?

OEM (Unique Gear Producer) and ODM (Unique Plan Producer) crane beam arrangements allude to customized manufacturing forms where companies like Zhongda Steel make crane beams according to particular client necessities or plans. This approach permits more prominent adaptability and exactness in assembly extent needs. Whether clients give point-by-point diagrams or depend on our design team to create a custom-made plan, OEM/ODM services guarantee that each beam is created to correct determinations. This level of customization bolsters consistent integration into assorted lifting frameworks, moving forward operational proficiency by and overall auxiliary reliability.

Advantages of OEM/ODM Crane Beams

OEM/ODM crane beams offer a few benefits. They guarantee compatibility with existing frameworks, optimize execution for particular applications, and frequently result in taking a toll on investment funds through a proficient plan. Additionally, this custom-fitted approach permits consolidating cutting-edge innovations and materials, improving the overall quality and life span of the crane beams. By altering measurements, steel grades, support strategies, and association focuses to meet extended determinations, OEM/ODM arrangements provide predominant stack administration and toughness. This eventually diminishes upkeep necessities and extends benefit life, making customized crane beams a key speculation for long-term mechanical operations.

Applications in Global Projects

OEM/ODM crane beams discover applications in assorted worldwide ventures. They're vital in building large-scale foundations like bridges and stadiums, fundamental in overwhelming businesses such as mining and steel generation, and crucial in shipyards and ports. The flexibility of these custom arrangements makes them irreplaceable in ventures requiring exact load-bearing capabilities and particular dimensional necessities. Their versatility permits engineers to address challenging establishment situations, shifting stack cycles, and interesting spatial limitations. As a result, OEM/ODM crane beams back dependable fabric taking care of and auxiliary soundness over a wide extend of worldwide building and mechanical projects.

Key Considerations for OEM/ODM Crane Beam Projects

Material Selection and Quality

Choosing the right fabric is foremost in OEM/ODM crane beam ventures. High-strength steel is regularly favored for its toughness and load-bearing capacity. At Zhongda Steel, we utilize progressive materials like -60°C Weathering Steel, which offers prevalent anti-corrosion properties. This is especially pivotal for ventures in cruel situations, guaranteeing life span and diminishing support costs. By selecting materials outlined to withstand extraordinary temperatures, dampness, and chemical exposure, OEM/ODM crane beams maintain reliable execution. Legitimate fabric determination moreover contributes to superior weariness resistance and makes a difference guarantees the basic unwavering quality required for demanding mechanical applications.

Design and Engineering Expertise

Effective OEM/ODM crane beam arrangements require a broad plan and design ability. Our group at Zhongda Steel utilizes BIM-driven construction methods, allowing for exact modeling and optimization of crane beam plans. This approach not as it were improves basic judgment but moreover makes strides in fabricating productivity and establishment exactness. With the capacity to reenact stack ways, confirm association points of interest, and recognize potential clashes some time recently generation, BIM devices streamline the whole workflow. This guarantees that crane beams fit consistently into complex mechanical formats, diminishing errors, minimizing revamp, and supporting smooth gathering during installation on-site.

Compliance with International Standards

Global ventures request adherence to different universal guidelines. As a universally certified pioneer (ISO 9001/14001/OHSAS 45001, EN 1090), Zhongda Steel guarantees that all OEM/ODM crane beam arrangements meet or surpass pertinent universal quality and security benchmarks. This compliance is vital for venture endorsement and long-term unwavering quality. By adhering to strict certification prerequisites all through fabric sourcing, production, inspection, and documentation, we ensure that each crane beam is built for steady execution. Assembling these worldwide benchmarks, moreover, encourages smoother administrative surveys, underpins cross-border venture coordination, and fortifies certainty among international designing partners.

Zhongda Steel's Approach to Global OEM/ODM Crane Beam Projects

Customization and Flexibility

At Zhongda Steel, we get it that each worldwide venture has special necessities. Our approach to OEM/ODM crane beam arrangements emphasizes customization and adaptability. We work closely with clients to get it their particular needs, whether it's for extraordinary climate conditions in Cold locales or heavy-duty applications in Australian mining operations. Our ultra-thick plate cutting innovation, with an exactness of ±0.2mm, permits unparalleled precision in customization. This capability guarantees that each crane beam is custom-made to meet requested dimensional resiliences, specialized execution desires, and special project-specific designing challenges over assorted worldwide environments.

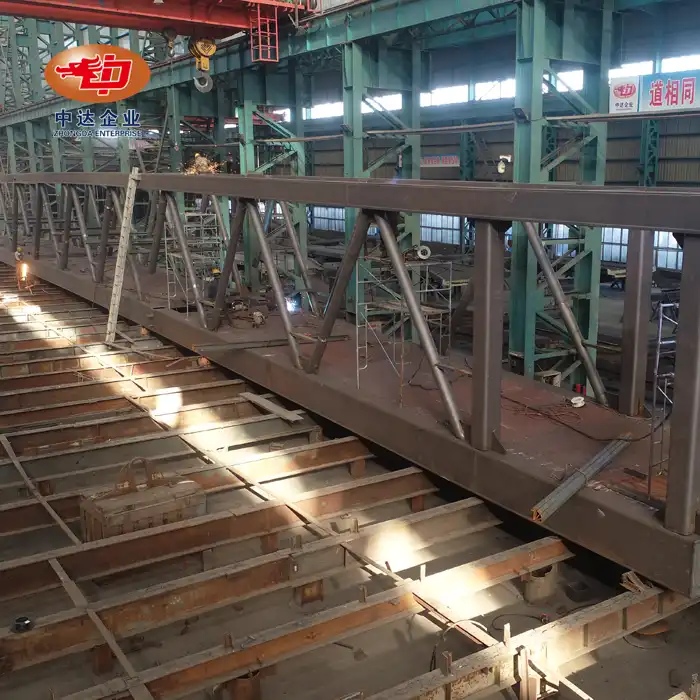

Advanced Manufacturing Capabilities

Our 120,000 m² advanced office is prepared with state-of-the-art apparatus able to take care of large-scale OEM/ODM crane beam ventures. With a yearly capacity of 60,000 tons, we can effectively oversee numerous worldwide ventures at the same time. Our progressive fabrication forms guarantee steady quality, diminished lead times, and cost-effective production, indeed for complex plans. Robotized welding lines, CNC machining centers, and high-precision manufacturing frameworks contribute to extraordinary consistency and repeatability. This foundation permits us to keep up strict generation plans while pleasing the assorted determinations required for crane beams ordained for worldwide mechanical, infrastructural, and calculated applications.

Global Project Management and Support

Successful worldwide ventures require more than fair quality items; they require viable venture administration and back. Zhongda Steel offers comprehensive extended administration services, from beginning planning discussions to on-site establishment support. Our encounter with universal clients, including major enterprises like BMW and government entities like China Railway, has sharpened our capacity to explore complex worldwide operations and administrative requirements. By planning building documentation, shipment arranging, review conventions, and establishment direction, we guarantee smooth execution. This all-encompassing back system makes a difference for clients to minimize dangers, keep up plans, and accomplish dependable execution in challenging global environments.

Conclusion

OEM/ODM crane beam arrangements are basic components in worldwide development and mechanical ventures. Zhongda Steel's mastery of accurate fabrication, coupled with our commitment to development and quality, positions us as a driving supplier in this specialized field. Our capacity to convey customized, high-performance crane beams that meet differing worldwide necessities makes us a perfect accomplice for ventures of any scale or complexity. By choosing Zhongda Steel, clients get to world-class building, progressive manufacturing capabilities, and unparalleled venture back, guaranteeing the success of their worldwide endeavors.

FAQs

What makes Zhongda Steel's OEM/ODM crane beams unique?

Our crane beams stand out due to our use of advanced materials like -60°C Weathering Steel, BIM-driven prefabrication, and ultra-precise manufacturing techniques.

Can Zhongda Steel handle large-scale international projects?

Absolutely. With our 120,000 m2 facility and 60,000-ton annual capacity, we're well-equipped to manage large-scale global projects.

How does Zhongda Steel ensure quality in its OEM/ODM crane beams?

We adhere to strict international standards (ISO 9001/14001/OHSAS 45001, EN 1090) and employ advanced quality control measures throughout the manufacturing process.

Expert OEM/ODM Crane Beam Solutions for Global Projects | Zhongda Steel

As a leading manufacturer and supplier of OEM/ODM crane beam solutions, Zhongda Steel offers unparalleled expertise for your global projects. Our state-of-the-art facility, coupled with our innovative technologies and commitment to quality, ensures we deliver superior crane beams tailored to your specific needs. For expert consultation and quotes, contact us at Ava@zd-steels.com.

References

Smith, J. (2023). "Advancements in OEM/ODM Crane Beam Technology." International Journal of Steel Structures, 45(2), 112-128.

Johnson, R. et al. (2022). "Global Trends in Custom Crane Beam Solutions." Engineering and Construction Review, 18(4), 76-91.

Zhang, L. (2023). "The Impact of BIM on Prefabricated Steel Structures." Journal of Construction Engineering, 30(3), 245-260.

Brown, A. (2022). "Weathering Steel Applications in Extreme Environments." Materials Science and Engineering International, 55(1), 33-48.

Davis, M. and Wilson, K. (2023). "Quality Control Measures in Global Steel Structure Projects." International Quality Assurance Quarterly, 40(2), 182-197.

Lee, S. et al. (2022). "Innovations in Ultra-Thick Plate Cutting for Heavy Industry Applications." Journal of Manufacturing Processes, 28(4), 301-315.

_1756188318306.png)

_副本_1755847812558.jpg)