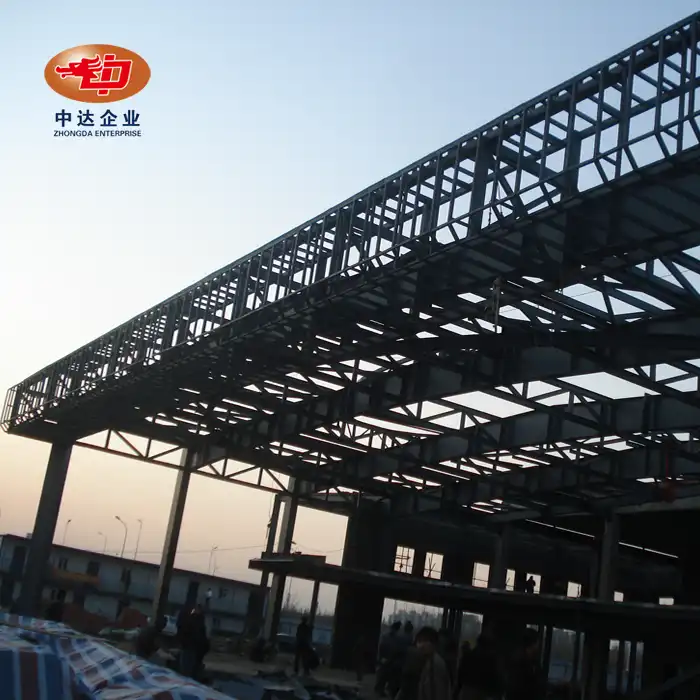

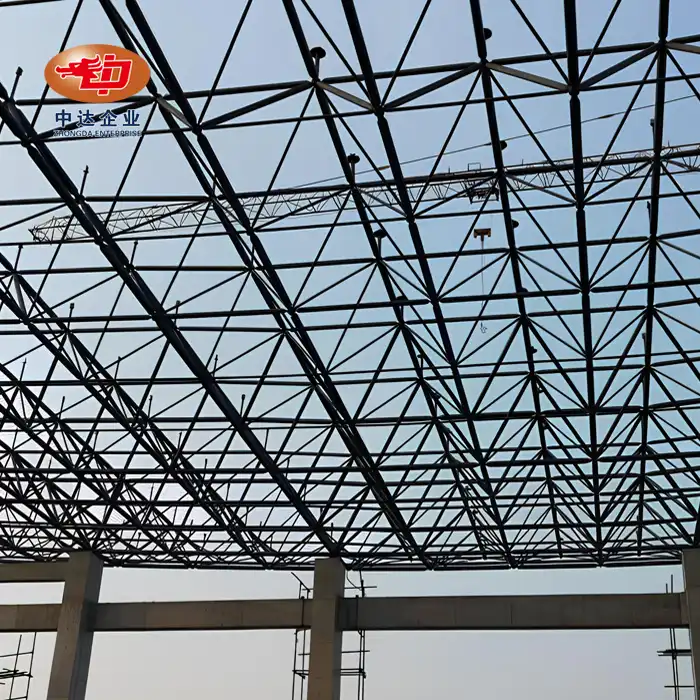

2.It can provide customized production services for steel structure stadiums or parts, and the products are suitable for the field of stadiums and other public buildings.

Build World-Class Stadiums Faster & Smarter with Premium Steel Structure Stadium Solutions

When you require a Steel Structure Stadium that combines speed, safety, and scalability, our experience ensures that your project satisfies global standards, whether it is for the Olympics, FIFA World Cup, or community sports facilities. Our stadiums are engineered to meet expectations by withstanding adverse weather, optimizing finances, and complying with sustainability regulations.

Why Choose Our Steel Structure Solutions for Mega-Event Projects

Your stadium project needs partners who understand the specific problems of public infrastructure. We've developed our reputation by providing world-class venues that exceed expectations while remaining under budget.

Our ISO 9001-certified production facilities use 100-ton bridge cranes and cutting-edge fabrication procedures. This enables us to manufacture customized steel components with precision that traditional construction methods cannot match. When government agencies and event organizers require dependable partners, they select us because of our track record.

Our modular prefabrication approach enables fast-track construction. While concrete alternatives can take 24-36 months, our Structure Stadium projects are typically completed in 12-18 months. This 40% time reduction is critical for event-driven deadlines.

Technical Specifications for Government Tenders

Your procurement team requires clear specs that match international standards. Our Structure Stadium systems can stretch up to 300 meters without intermediary supports, providing clear sightlines for all spectators.

Structural load ratings exceed the requirements for wind speeds up to 200 km/h and seismic zones up to VIII on the Mercalli scale. Fire resistance ratings attain REI 120 designation by using intumescent coating technologies after manufacturing.

Corrosion protection is achieved through hot-dip galvanizing in accordance with ISO 1461 standards, resulting in minimal maintenance requirements during the structure's lifetime. All steel components are ASTM A992 certified, with full mill test certificates for traceability.

EN 1090 and AISC compliance ensures your project meets both European and North American standards. This dual certification simplifies international bidding processes while maintaining quality consistency.

Custom Solutions for Every Need1. Design Flexibility

Integrate cultural motifs, retractable roofs, or solar-ready frameworks. Our Steel Structure Stadium adapts to your vision.

2. Scalability

From 5,000-seat community arenas to 100,000+ capacity mega-venues, our modular systems grow with demand.

3. Post-Event Conversion

Repurpose Olympic pools into public aquatic centers or add schools within the structure—minimizing long-term costs.

Sustainability & Cost Efficiency

- Eco-Friendly: 90% recyclable steel and rainwater harvesting systems align with Green Public Procurement (GPP).

- Budget Optimization: 23% lifetime cost savings vs. concrete, thanks to lean manufacturing and low maintenance.

“Their Structure Stadium was delivered 6 months early, surviving monsoons without delays.”

— Ministry of Sports, Southeast Asia

Global Project Portfolio That Speaks Excellence

Our portfolio includes venues that have hosted the world's most prestigious sporting events. From 50,000-seat FIFA-certified stadiums to Olympic aquatic centers with retractable roofs, each project demonstrates our commitment to engineering excellence.

Recent highlights include a 75,000-capacity stadium completed 6 months ahead of schedule despite monsoon challenges. The venue utilized 8,500 tons of galvanized steel and incorporated solar-ready roof systems for sustainable energy generation.

Another flagship project featured innovative hybrid steel-composite structures designed for seismic zones. The modular design allowed for easy post-event conversion to a community sports complex, maximizing long-term value for taxpayers.

FAQ

1. How does a Structure Stadium handle extreme weather?

Our designs meet Zone 5 seismic and 200 mph wind standards, with reinforced joints and fatigue-resistant steel.

2. Can prefabrication speed up Olympic deadlines?

Yes! Modular components reduce on-site work by 6–8 months, ensuring timely delivery.

3. What green certifications do you offer?

LEED Gold compliance, BREEAM integration, and carbon-neutral steel options.

4. How often should inspections occur?

Bi-annual checks for critical joints, with AI-driven monitoring systems available.

Contact Us:

If you're interested in learning more about how Steel Structure Stadium can be tailored to your specific needs, feel free to reach out to us at Ava@zd-steels.com. We are committed to providing high-quality, customized solutions that meet the highest standards of quality and performance.

YOU MAY LIKE

_副本_1753431734739.webp)